Blasting drilling device used for tunnel blasting construction

A drilling device and tunnel technology, which is applied to supporting devices, drilling equipment and methods, drilling equipment and other directions, can solve the problems of long time consumption, large manpower and material resources, affecting the tunnel construction period, etc., and achieves convenient installation and layout and investment cost. Low, easy to manufacture and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

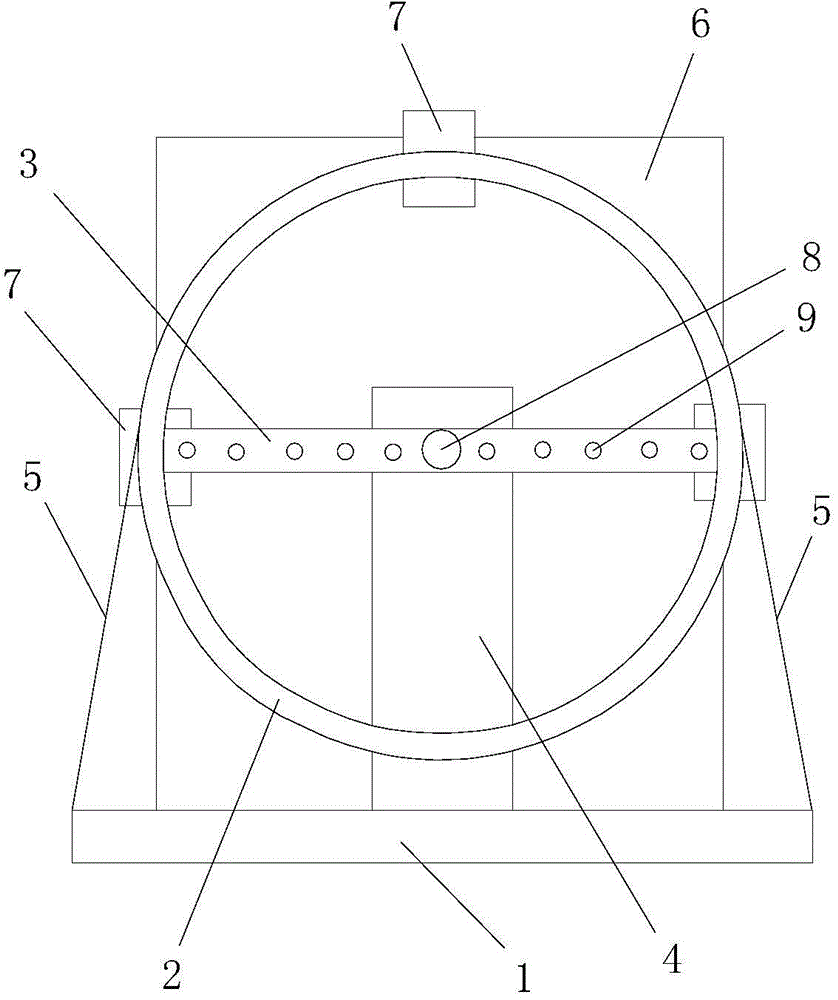

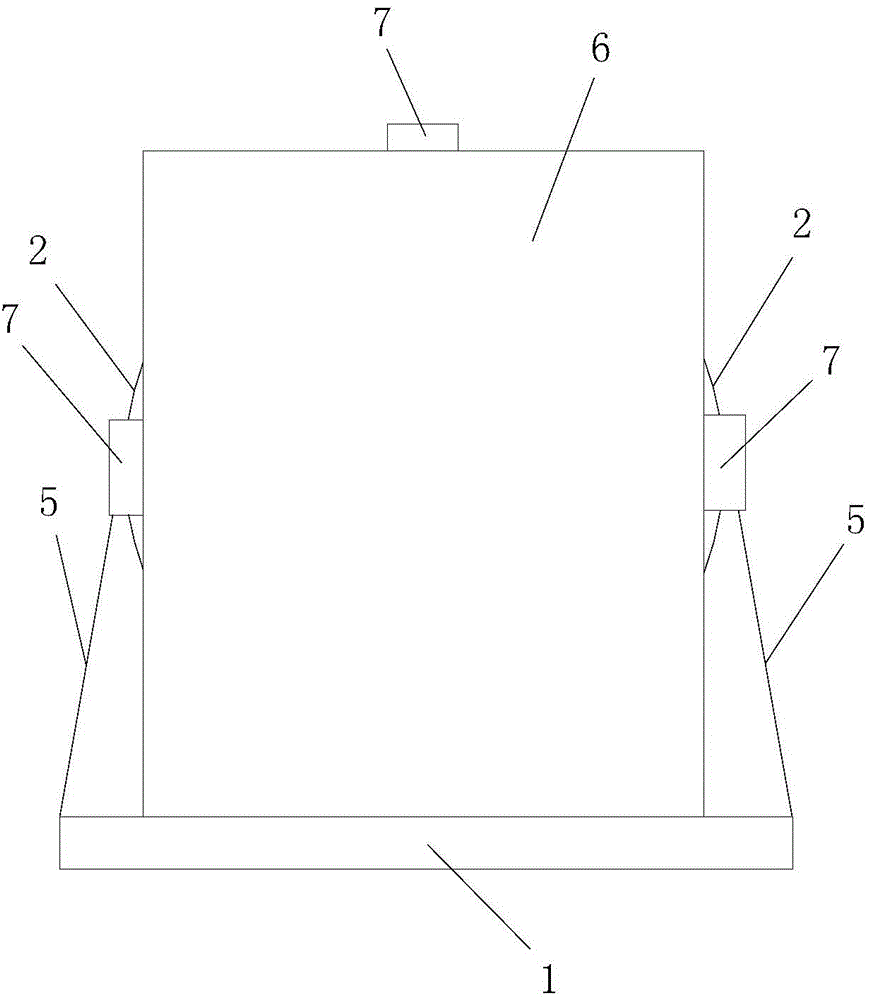

[0023] Such as figure 1 , figure 2 As shown, the present invention includes a horizontal platform base 1, a circular track 2 positioned above the front side of the horizontal platform base 1, a circular track 2 installed on the circular track 2 and capable of rotating 360° along the circular track 2 on a vertical plane. The drilling frame 3, the vertical mount 4 positioned at the rear side of the circular track 2 and the push plate 6 arranged on the rear side of the vertical mount 4, the push plate 6 is a rectangular shape arranged vertically plate. The circular track 2 is arranged vertically, and the drilling frame 3 is a strip frame and it is arranged on the same vertical plane as the circular track 2. The drilling frame 3 The length is the same as the diameter of the circular track 2 and its two ends are clamped on the circular track 2 . The horizontal platform base 1 is provided with two left and right track support seats 5 for supporting the circular track 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com