Lock cylinder and antitheft mortise door lock adopting same

A technology of lock cylinder and lock cylinder shell, which is used in construction locks, cylinder pin locks, locks with turning keys, etc. Anti-technical opening ability, good bending strength, high sheet density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

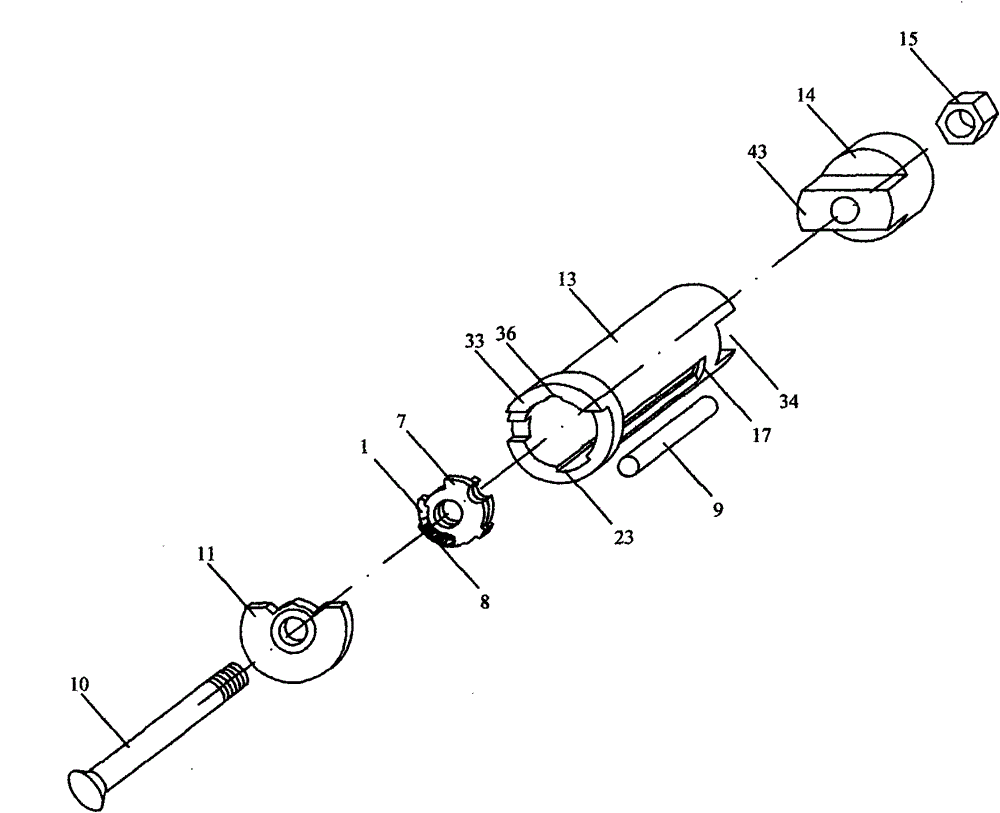

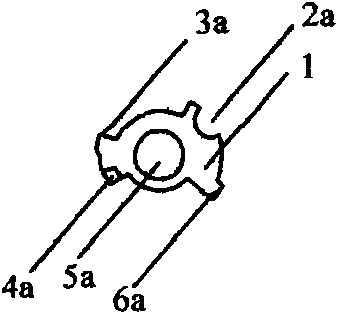

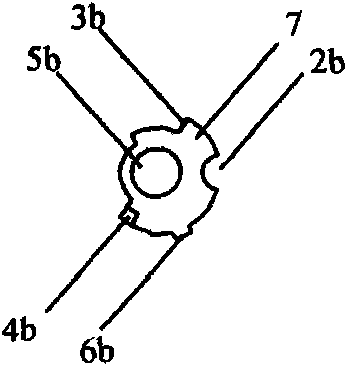

[0073] figure 1 It is an exploded view of the first embodiment of the lock cylinder of the present invention. The first embodiment of the lock cylinder 16 of the present invention includes a rotating shaft 10 , a front cover 11 , a left leaf 1 , a right leaf 7 , a spring 8 , a locking post 9 , a lock cylinder case 13 , a tail 14 and a nut 15 . The lock cylinder shell 13 is a hollow cylinder, with a first boss 33 at its front end and a groove 34 at its rear end. The front end of the tail part 14 has a second boss 43 . figure 1 Only a set of leaves consisting of left leaf 1, right leaf 7 and spring 8 is shown. In this embodiment, there are actually 5 sets of leaves. Each set of leaves is connected to the shaft 10. The left leaf 1 and the right leaf The pieces 7 can rotate around the rotating shaft 10 . Lock core outermost is the front cover 11 that is used for anti-drilling, and the central hole of front cover 11 is a circular hole, and the first boss 33 of front cover 11 and...

Embodiment 2

[0085] In the first embodiment of the lock cylinder 16 of the present invention, the position of the rotating shaft 10 is determined by the shaft holes on the front cover 11 and the tail 14, but the shaft holes on the front cover 11 and the tail 14 are difficult to ensure the axis of the rotating shaft 10 Aligned with the axis line of the lock cylinder shell 13, if the axis of the rotating shaft 10 deviates greatly from the axis line of the lock cylinder shell 13, the blades may rub against the inner wall of the lock cylinder shell 13, making the lock cylinder 16 does not work properly. In order to solve this problem, the front positioning sheet 12 can only be placed in front of the sheet group, and the rear positioning sheet 19 can only be placed behind the sheet group. Figure 14 , Figure 15 , Figure 16 with Figure 17 As shown, the second embodiment adopts the technical scheme of placing the front positioning piece 12 and the rear positioning piece 19 at the front and ...

Embodiment 3

[0089] In Embodiments 1 and 2 discussed above, the rotating shaft 10 encapsulates the leaf group in the lock cylinder case 13 through the front cover 11 , the tail portion 14 and the nut 15 . In this structure, the nut 15 takes up a lot of space, so that the number of sheets of the lock core 16 fails to reach the maximum. Figure 18 , Figure 19 with Figure 20 A third embodiment of the lock cylinder 16 of the present invention is shown. In this embodiment, there is a screw hole 56 on the tail part 14. Therefore, the screw hole 56 on the tail part 14 is directly used to screw on the thread at the tail end of the rotating shaft 10, and the nut 15 is eliminated to save the space it occupies. Figure 20 In the sectional view of the present embodiment, under the same lock cylinder length (the length of the mortise lock is 75 millimeters as the design length), a group of leaf sheets is added to reach 6 groups of 12 leaf sheets. In order to prevent the rotating shaft 10 from bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com