Direct cable weaving and hanging method for cable strand of suspension bridge

A suspension bridge and cable technology, applied in the field of suspension cables of bridges, can solve the problems of only a few tens of wires to more than one hundred wires, the bulk of the anchorage, and the increase of material consumption, saving manpower and reducing the size of the anchorage. The effect of reducing the number of anchors and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for directly weaving and hanging cables on site for main cable strands of a suspension bridge, comprising sequentially setting weaving equipment, weaving unit strands, pulling unit strands, hot-casting anchors, cooling anchors, installing strand anchors and linear adjustment. 7 steps, the specific steps are as follows:

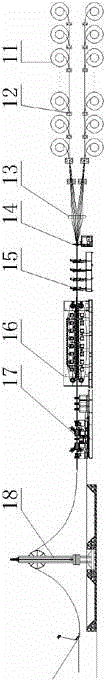

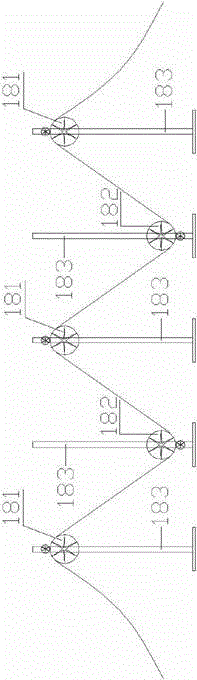

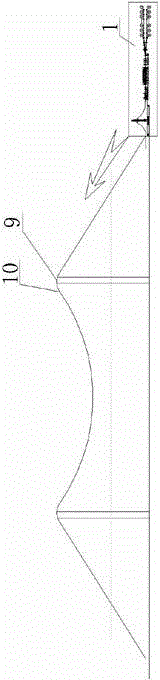

[0018] When setting up the compilation device, such as figure 1 As shown, the weaving area is set at one end of the suspension bridge tower at the main cable hanging cable construction site, and the weaving equipment 1 is set in the weaving area. Closing device 14, shaping wheel 15, traction unit machine 16, wrapping machine 17 and transition device 18 are formed, and transition device 18 is as figure 2 As shown, it consists of 3 fixed pulleys 181, 2 movable pulleys 182 and 5 pillars 183, the fixed pulley 181 is fixed on the pillars 183, the movable pulley 182 is set on the pillars 183 and slides up and down along the pillars 183, the fixed p...

Embodiment 2

[0026] A method for directly weaving and hanging cables on site for main cable strands of a suspension bridge, comprising sequentially setting weaving equipment, weaving unit strands, traction unit strands, hot-casting anchors, cooling anchors, installing strand anchors, tensioning and Linearly adjust these 8 steps. After setting up the braiding equipment, the braiding unit strands and the traction unit strands are carried out at the same time, that is, the front end of the steel wire starts to pull the unit strands after the braiding of the unit strands is completed, and the rear end of the steel wire continues to weave the unit strands. Strands, and the speed of the traction unit of the steel wire when compiling the unit strands is consistent with the speed of the traction unit of the unit strands when pulling the unit strands. Other steps are all the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com