Powerful grinding sand disk

A powerful grinding and sanding disc technology, applied in the direction of abrasives, bonded grinding wheels, metal processing equipment, etc., can solve the problems of poor moisture resistance or water resistance, unstable safety performance, unsuitable for outdoor operations, etc., and achieve low cost and excellent structure. Simple, anti-centrifugal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

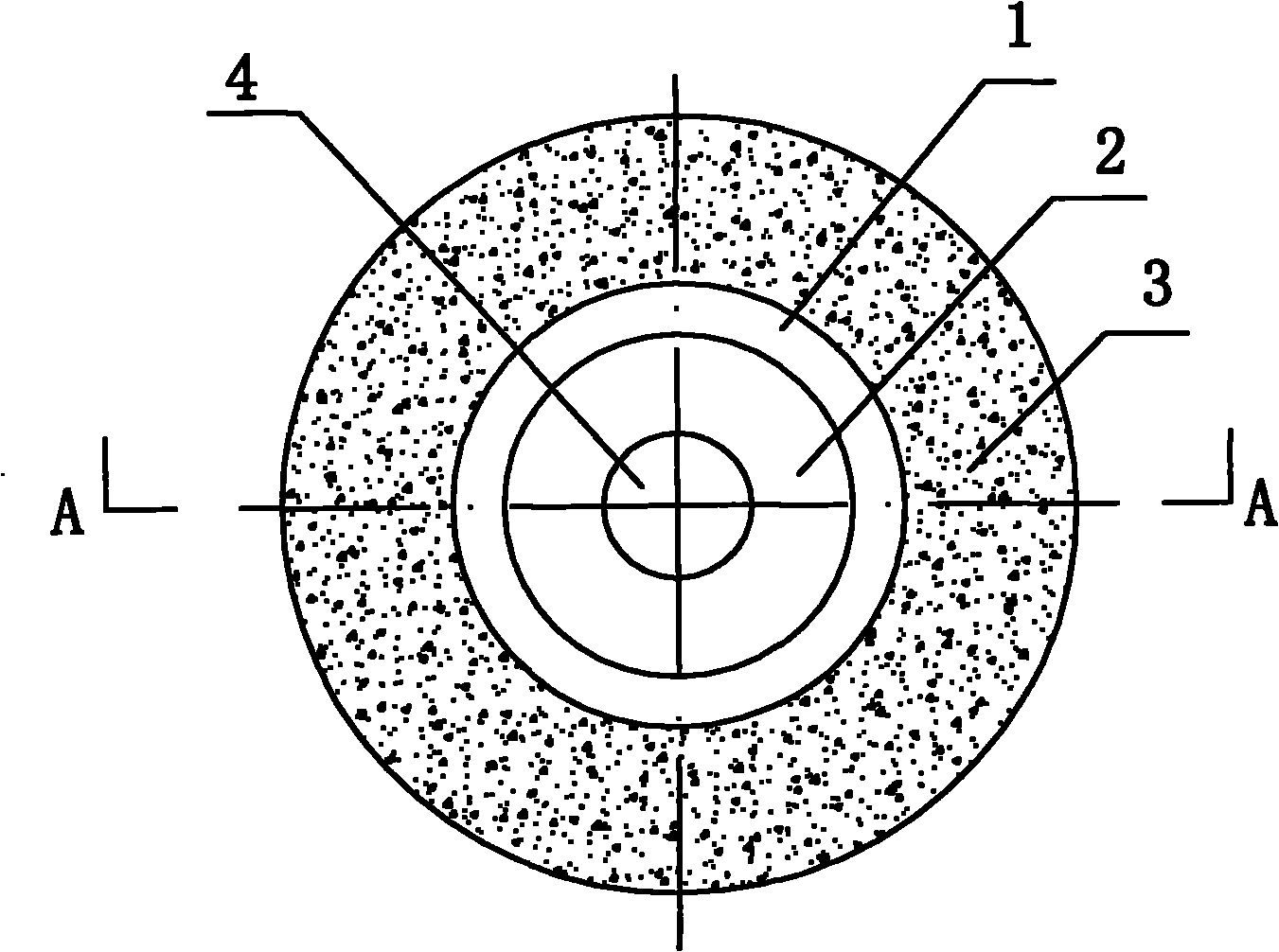

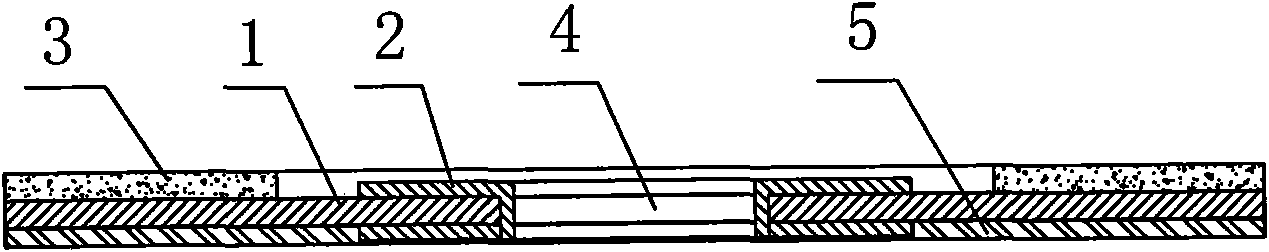

[0012] Such as figure 1 , figure 2 , image 3 As shown, the powerful grinding sand disc includes a base body 1, a reinforcement ring 2, and a grinding working layer 3; a through hole 4 is provided in the middle of the base body 1, and a reinforcement ring 2 (or called Reinforcement ring, the periphery is wrapped with a reinforcement ring); the front of the substrate 1 is provided with a ring-shaped grinding working layer 3, and the reinforcing ring 2 is located on the inner side of the grinding working layer 3 (such as figure 1 shown); the material of the base body 1 contains glass fiber or polyester cotton (or contains glass fiber and polyester cotton).

[0013] The material of the reinforcing ring 2 is metal (or other materials).

[0014] The opposite side (or claiming the back side) of described base body 1 is glued with one deck ring-shaped paper 5 (20g / m 2 -200g / m 2 ), the middle part of paper 5 is a through hole.

[0015] The preparation of matrix 1 includes any o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com