Lifting punching device

A technology of punching device and punch, which is applied in the direction of punching tools, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing mold manufacturing cost, reducing production efficiency, and increasing mold change time, so as to achieve low manufacturing cost and improve production Efficiency, the effect of saving development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

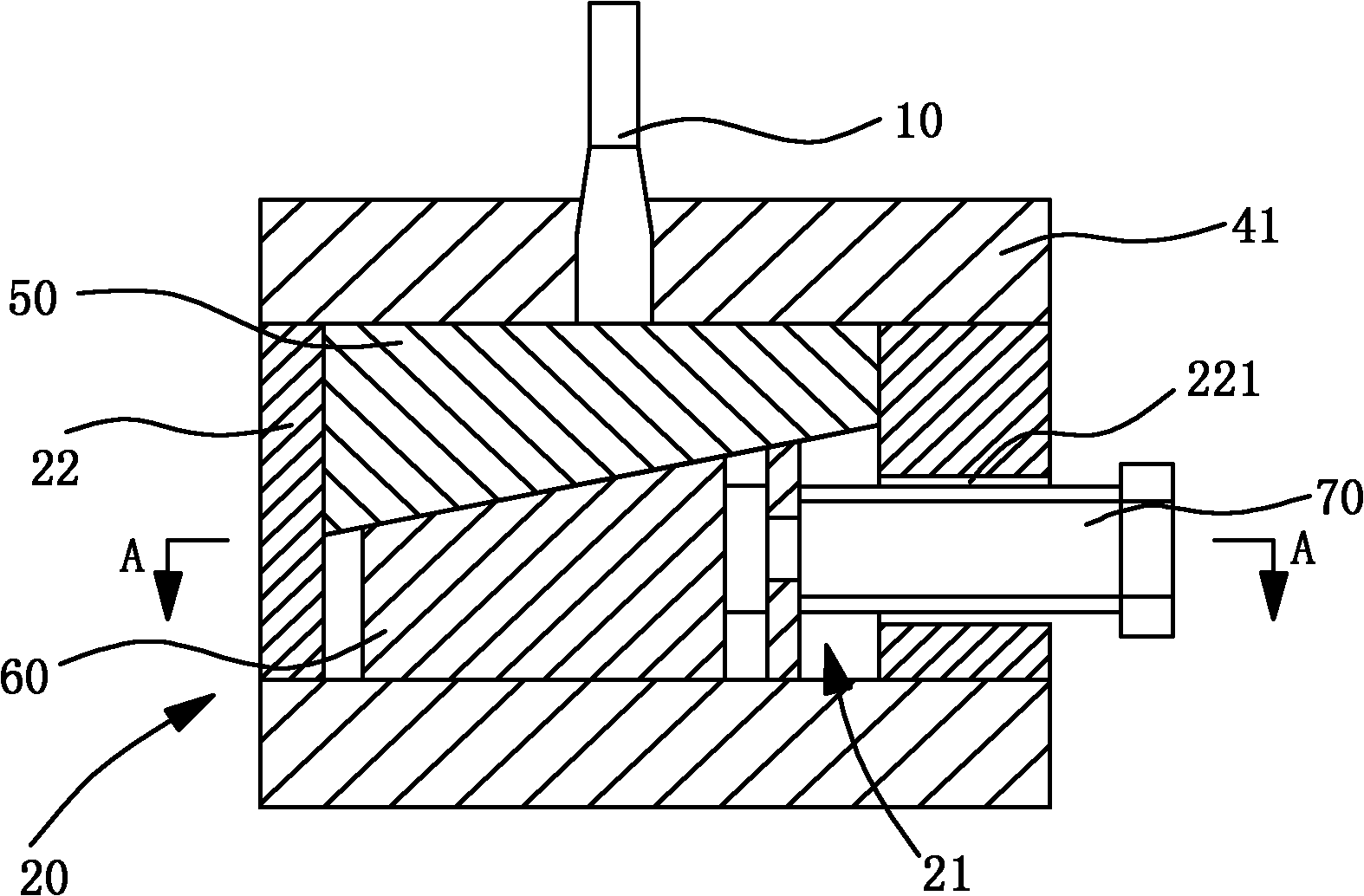

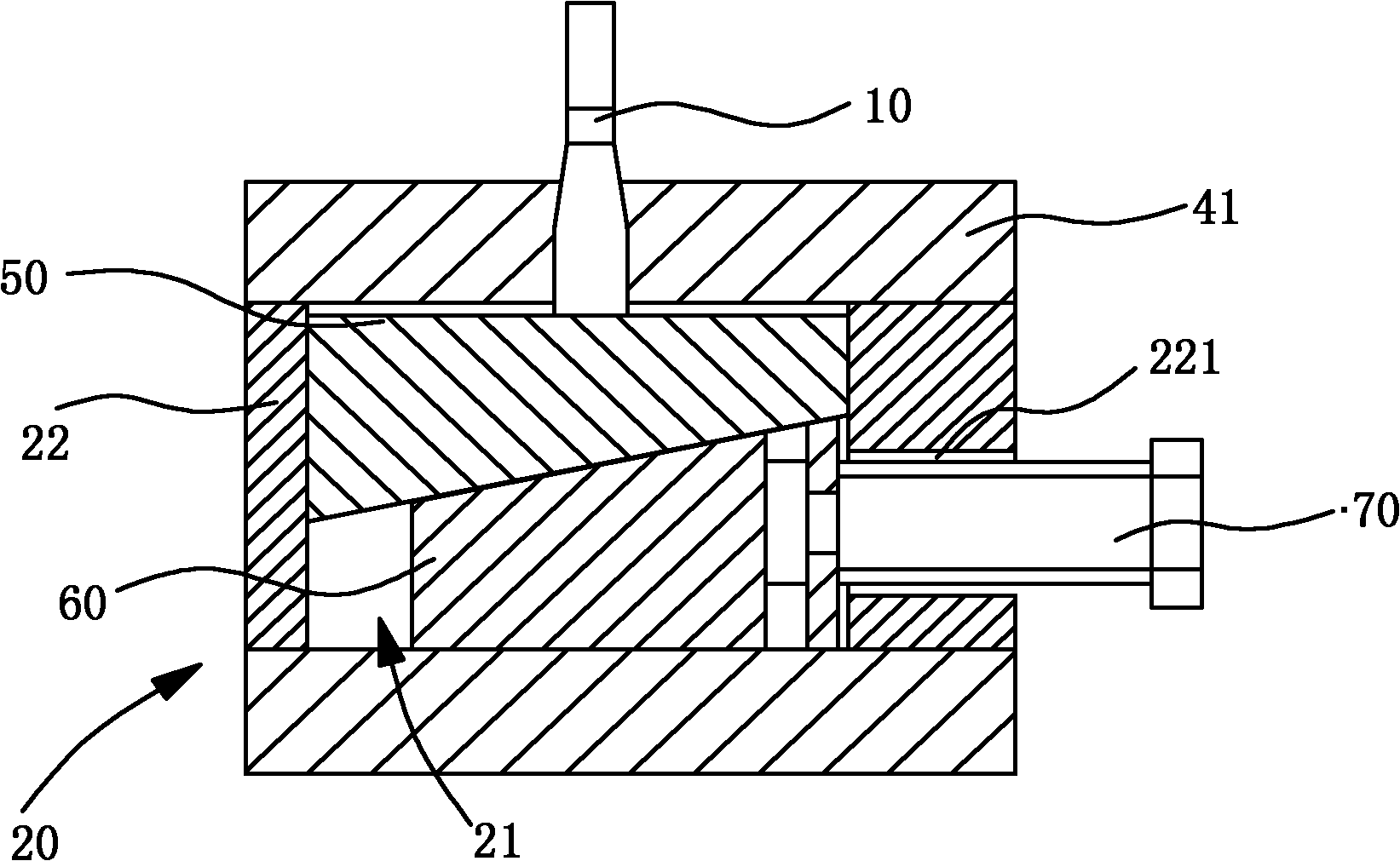

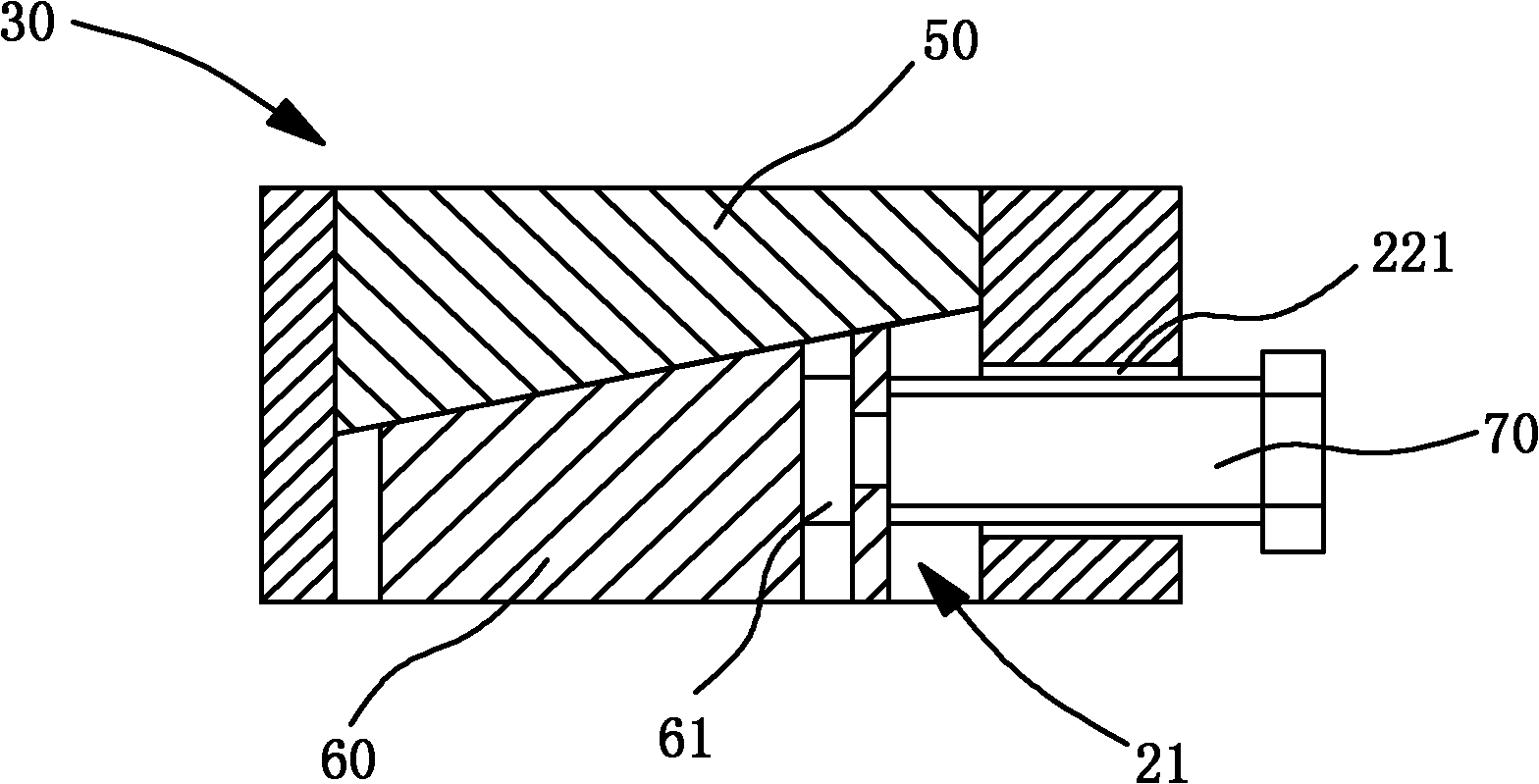

[0011] A lifting punching device, the punch 10 is set on the die base 20, and the die base 20 is provided with an adjustment mechanism 30 for adjusting the height of the punch 10 and a limit mechanism 40 for limiting the movement direction of the punch 10. When punching is required, the punch 10 can be raised by the adjusting mechanism 30 ; when punching is not needed, the punch is also lowered by the adjusting mechanism 30 . The limit mechanism 40 is mainly used to ensure that the punch 10 is always lifted and lowered in the vertical direction during the process of raising and lowering, so as to achieve the purpose of accurate punching.

[0012] The adjustment mechanism 30 includes upper and lower sliders 50, 60 that move in opposite directions, the mating surface between the upper and lower sliders 50, 60 is an inclined plane, and the upper and lower sliders 50, 60 are located in the mold cavity of the mold base 20 21, the upper end surface of the upper slider 50 is attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com