Precast block for building

A prefabricated block, construction technology, applied in building materials, building components, thermal insulation, etc., can solve the problems of inability to meet people's needs, inability to achieve thermal insulation effect, inability to split and reuse, etc., to save manpower and construction. Materials, excellent thermal and sound insulation performance, and low cost of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

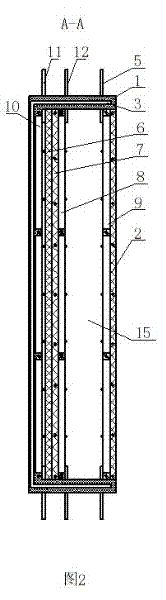

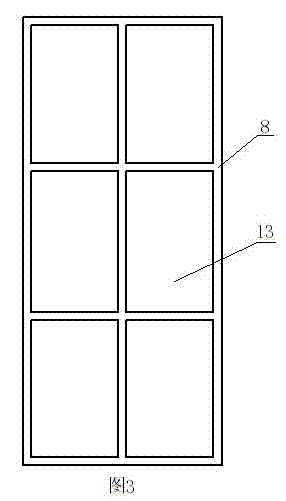

[0009] The building prefabricated block of the present invention comprises shell 1, according to common construction needs, such as figure 1 The front of the housing 1 shown can be rectangular or square. A cavity 15 is provided in the housing 1, and several second connectors 11 are installed on the side walls around the cavity 15; in the cavity 15, the insulation board 6, the partition plate 7 and the first fixing frame 8 are sequentially installed from the inside to the outside; Several third connectors 12 are installed on the side walls around the cavity 15, and one end of the third connectors 12 is positioned at the position of the first fixed frame 8 in the cavity 15; One connecting piece 5, one end of the first connecting piece 5 is located in the cavity 15, the second fixing frame 9 and the cover plate 2 are installed in the cavity 15, and the second fixing frame 9 is located between the cover plate 2 and the first connecting piece 5 , the cover plate 2 is located on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com