Anti-rotation ejection mechanism for automotive mold

A technology of jacking mechanism and automobile mould, which is applied in the field of anti-rotation jacking mechanism, which can solve the problems of high cost, large demand space, and unstable lifting of parts, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

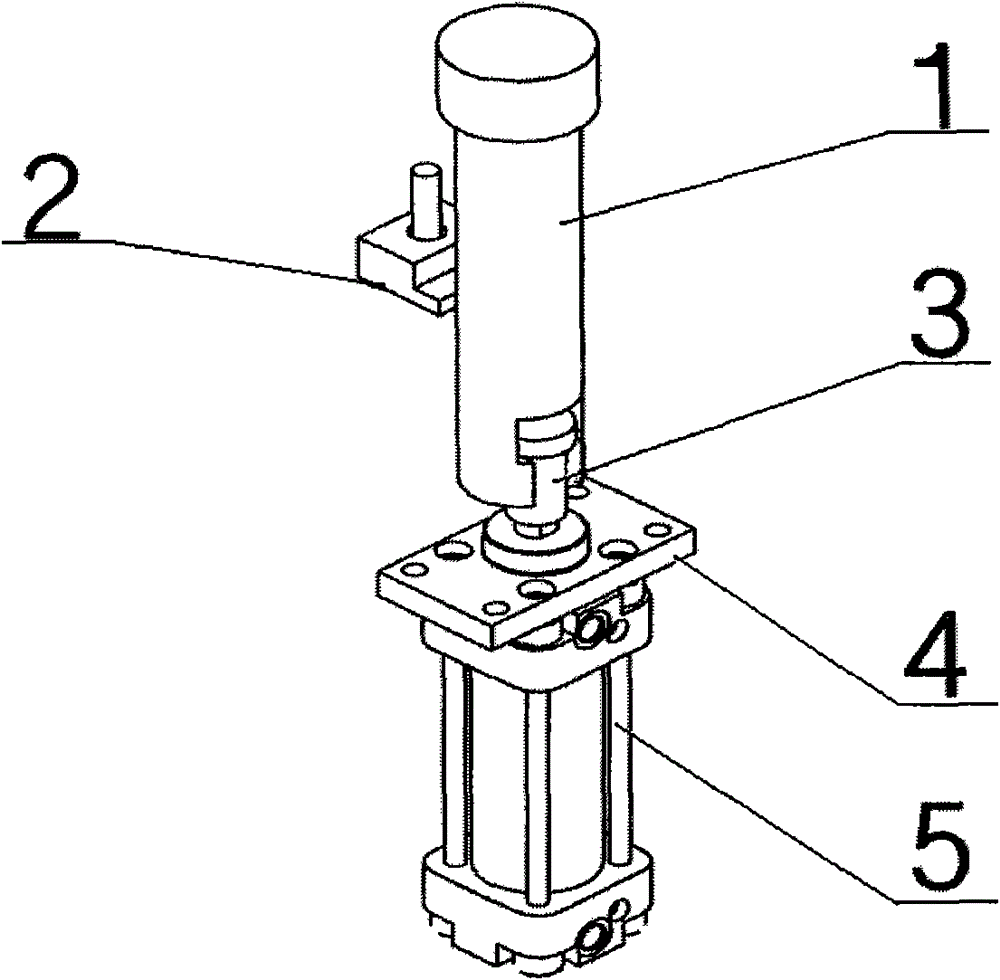

[0011] An anti-rotation jacking mechanism for automobile moulds, including a piston rod connecting rod 1, a pressure plate 2, a cylinder joint 3, a cylinder front flange 4 and a cylinder 5, and the piston rod connecting rod 1 is a T-shaped cylinder and is arranged on the mold In the lower mold body 6, the piston rod connecting rod 1 includes a T-shaped top at the upper end, a connecting rod in the middle and a groove at the lower end. The height is the same, and there is an anti-rotation plane on the connecting rod; the cylinder 5 is fixed on the lower mold body 6 of the mold through the cylinder front flange 4, the cylinder joint 3 is fixed with the cylinder 5 through threaded connection, and the cylinder joint 3 is inserted into the piston rod connecting rod 1 In the groove; the pressure plate 2 is fastened on the lower mold body 6 of the mold by screws, and its vertical surface is slidingly matched with the anti-rotation plane on the piston rod connecting rod 1.

[0012] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com