Engaging relay for starters of internal combustion engines

A starting relay and starter technology, which is applied in the direction of engine starting, relay, engine motor starting, etc., to achieve the effect of avoiding space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

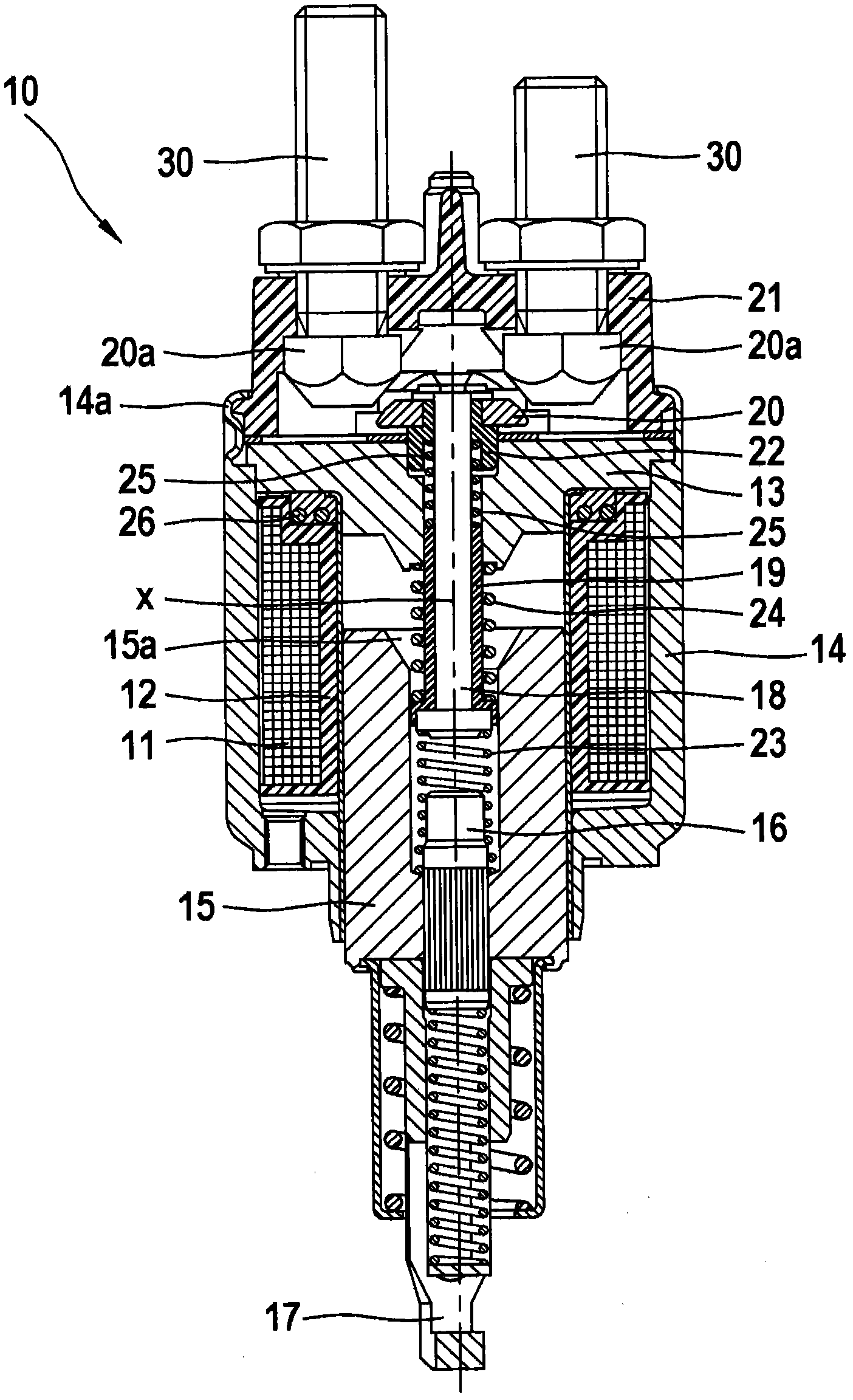

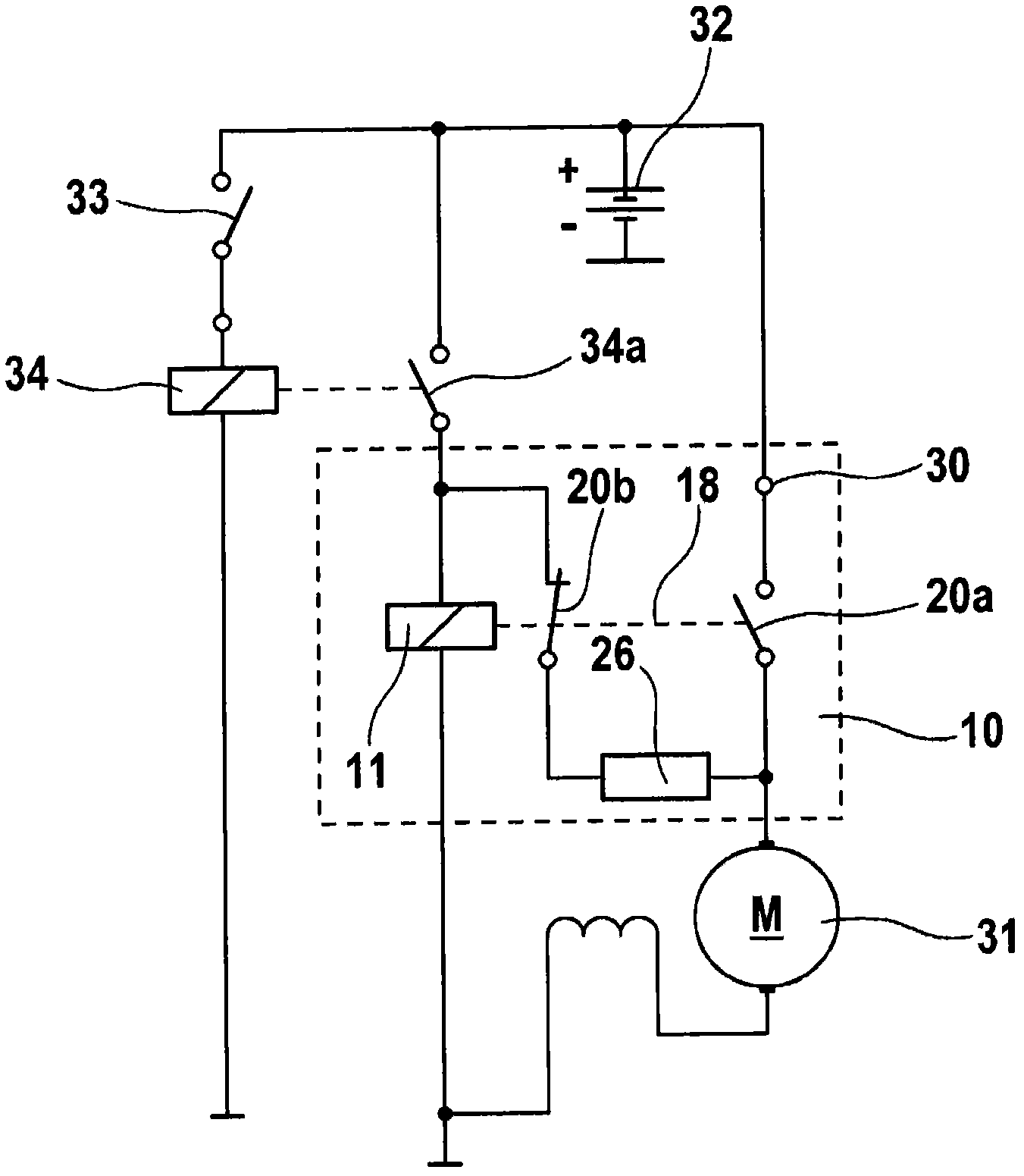

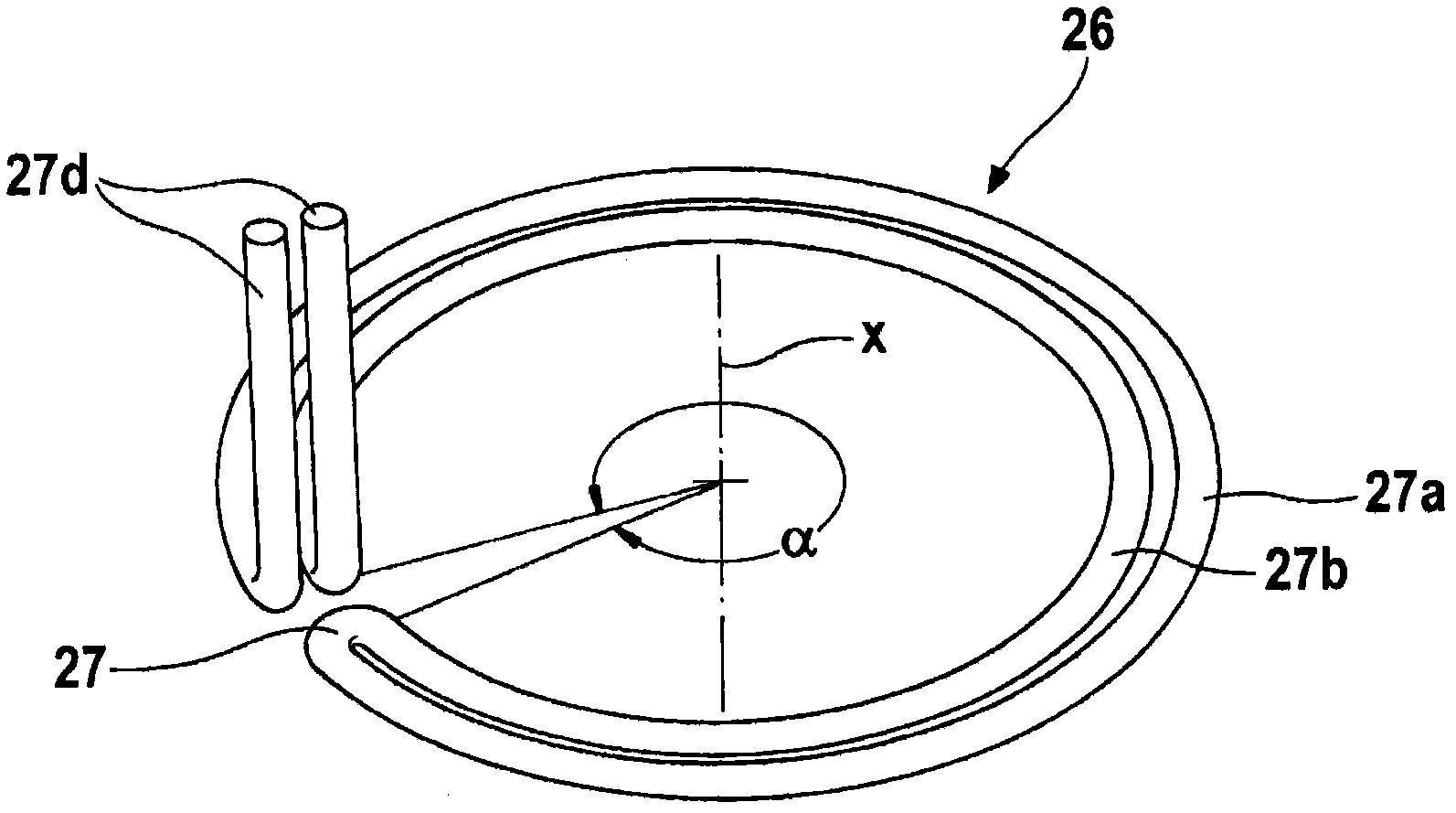

[0026] figure 1 Designated at 10 is a design of a starter relay for a starter of an internal combustion engine in a motor vehicle. The starter relay 10 has a relay coil 11 on a coil carrier 12 made of plastic, which is fastened to a pole core 13 . In this case, the relay coil 11 is accommodated in a metal housing 14 in which a pole core 13 is accommodated in its open front end. On the bottom of the housing 14 , an armature 15 of the relay, which sinks into the relay coil 11 , is guided axially in a bore. A push rod 16 is fixed in the central hole of the armature 15, the top end of which has a so-called paddle 17 to accommodate a meshing rod for a not shown starter pinion. In the through-opening of the pole core 13 , an actuating rod 18 is guided by means of an insulating sleeve 19 , wherein the front end of the actuating rod 18 is arranged at a distance from the end of the push rod 16 . On the rear end of the operating rod 18 is accommodated axially displaceably a contact b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com