Electric machine and method for manufacturing and/or assembling electric machine

A technology of armature shaft and starting mechanism, which is applied in the direction of machine/engine, engine control, engine starting, etc., and can solve the problems of function loss, starter noise, power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

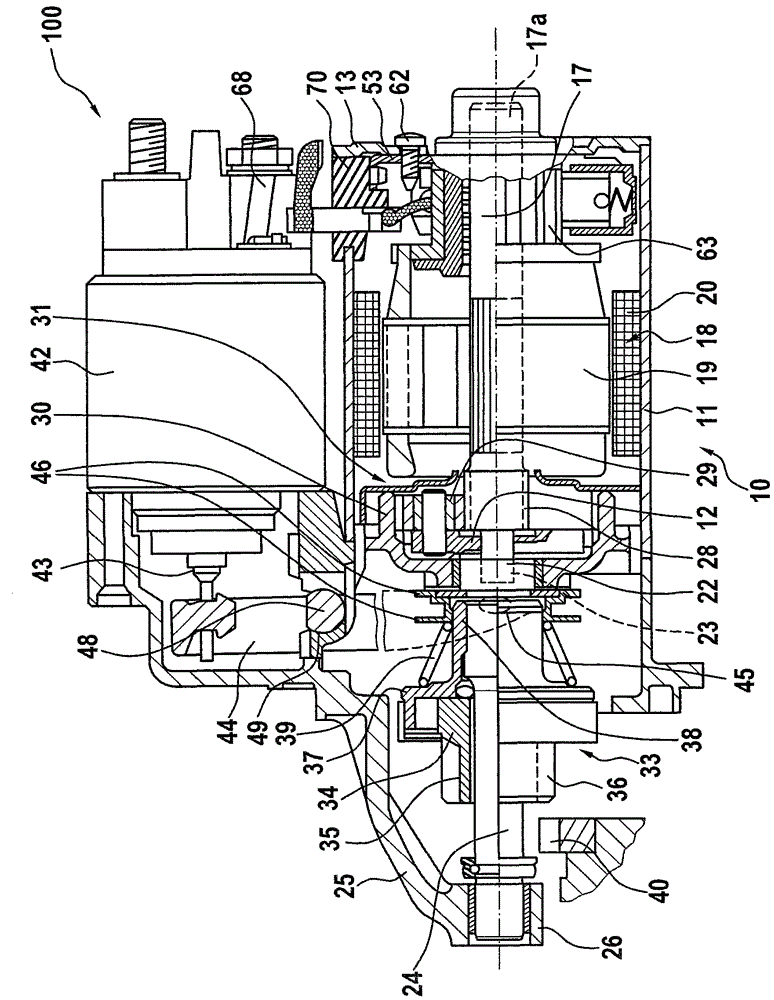

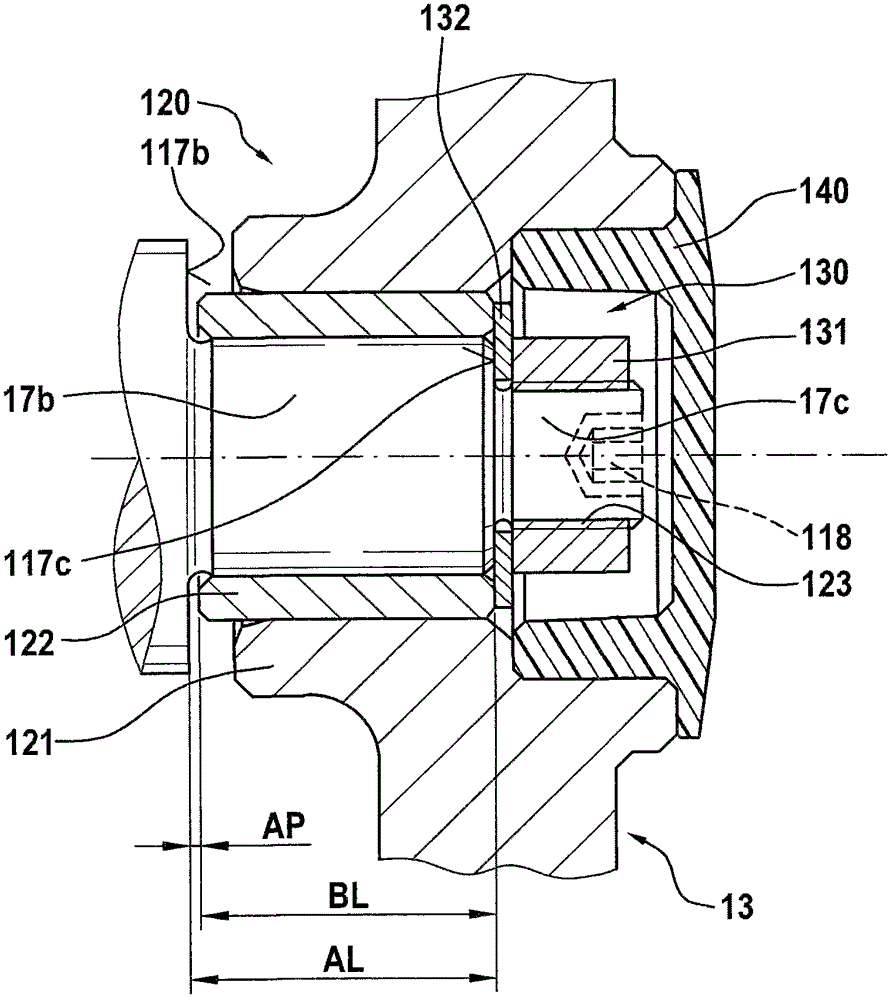

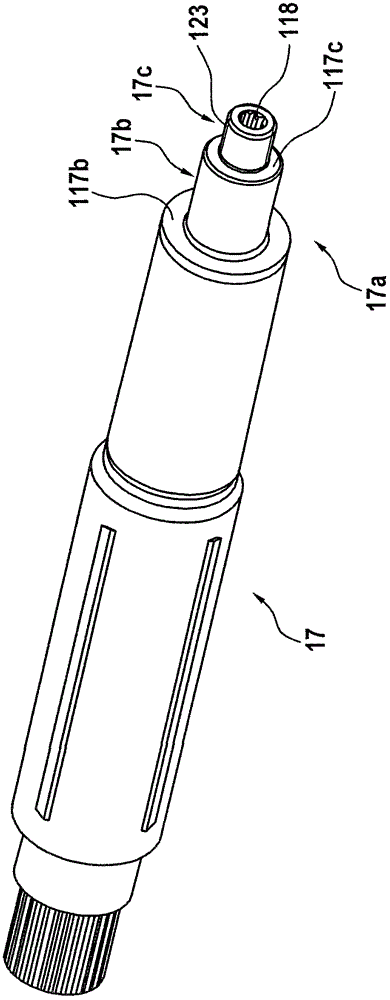

[0035] figure 1 An electric machine 100 in the form of a starter or starter motor is shown in section with a relay 42 arranged as a switching relay or switching relay. The starter housing 10 of the starting device comprises a cylindrical housing part 11 and a housing cover or housing cover 13 which are connected to each other by screws (not shown). The cylindrical housing part 11 is closed at the rear by said cover 13 . In the central area of the cover 13 is formed a hub or (drive) collar 121 directed towards the outside of the starter. A bearing region is formed on the inside of the collar 121 , in which the armature shaft of the electric starter motor 18 , the rotor shaft or the rear end 17 a of the drive shaft 17 is supported. The armature of the electric starter motor 18 is identified with the reference numeral 19 . Radially outside the armature 19 , a plurality of (permanent) magnets 20 of the electric starter motor 18 are arranged on the wall of said housing part 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com