Printing bottoming method and device adopting same

A technology of laying the background and color blocks, which is applied in the direction of image communication, electrical components, etc., can solve the problems of inability to handle objects with special effects in images, poor support for gradient objects, etc., and achieve clear and bright printing effects, undistorted printing effects, good visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

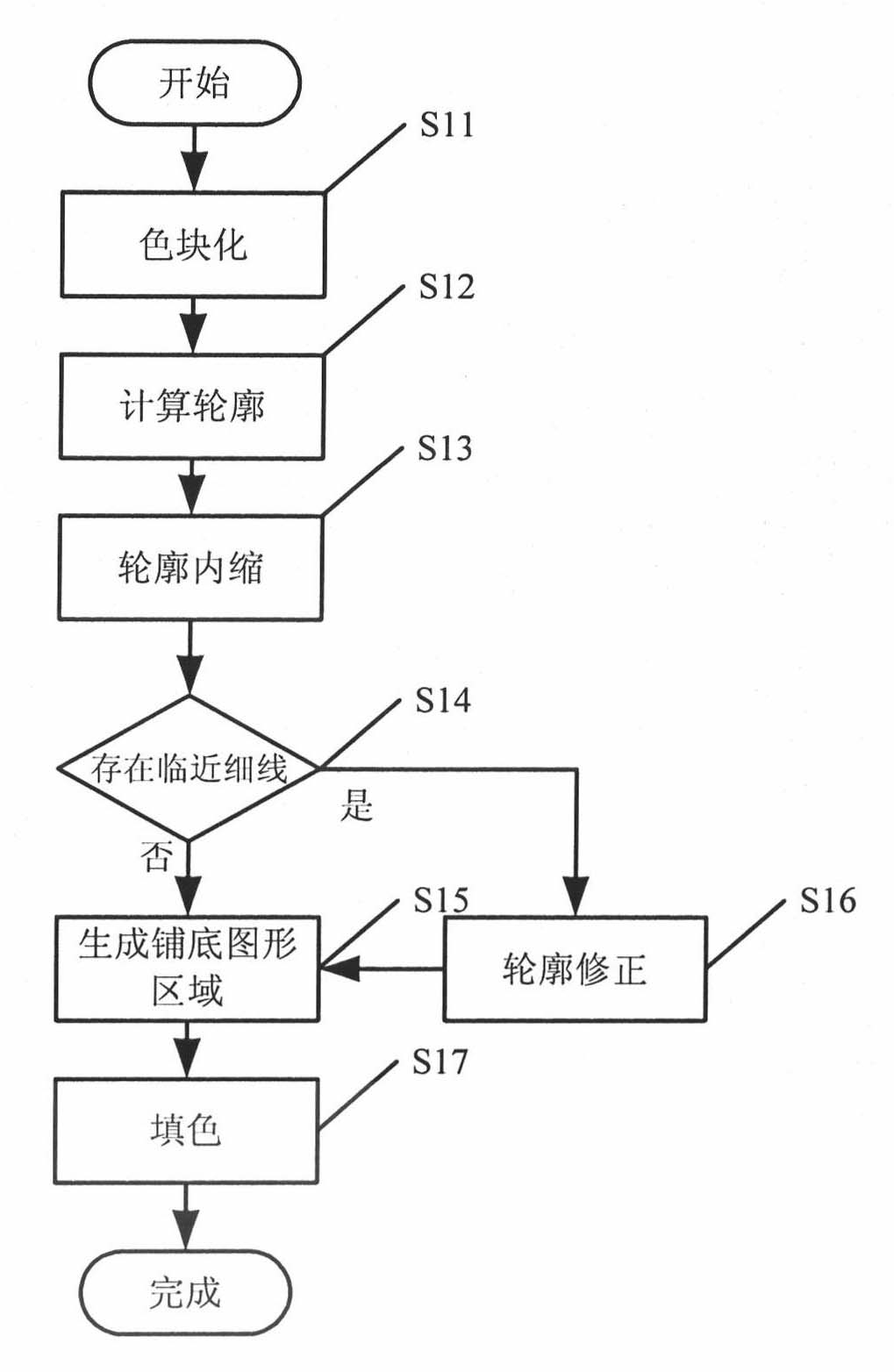

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0044] The invention provides a printing bottom laying device, which mainly includes the following modules:

[0045] Color block generation module: used for color block processing of all objects on the layout to generate color blocks, and to mark the color block type;

[0046] Bottom contour generation module: used to obtain the overall contour of adjacent color blocks according to the above-mentioned generated color blocks, and shrink back to obtain the bottom contour;

[0047] Pavement contour correction module: used to correct the pavement contour when there are adjacent thin line objects in the pavement contour;

[0048] Pavement graphic block generation module: used to merge the corrected pavement outline with the color-blocked graphic outline to generate a new pavement graphic block;

[0049] Base color filling module: used to fill the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com