High-voltage battery charging system architecture of electric automobile

A high-voltage battery and electric vehicle technology, which is applied in the direction of electric vehicle charging technology, electric vehicles, battery circuit devices, etc., can solve the problems of complex winding process of transformers, increased circuit loss, long charging time, etc., and achieves low manufacturing cost and reduced loss , The effect of short charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention is capable of various changes in different ways without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature rather than limiting the present invention.

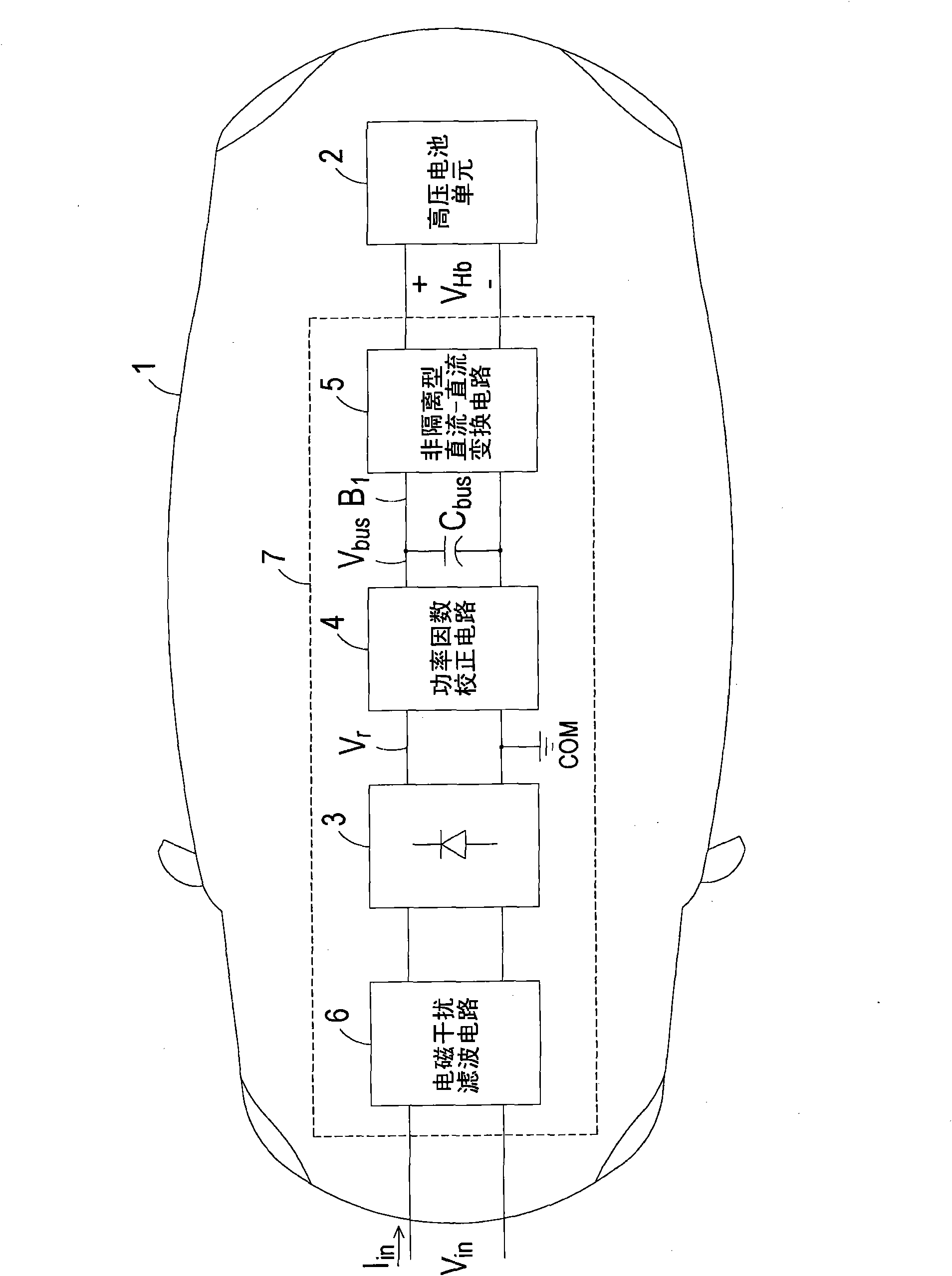

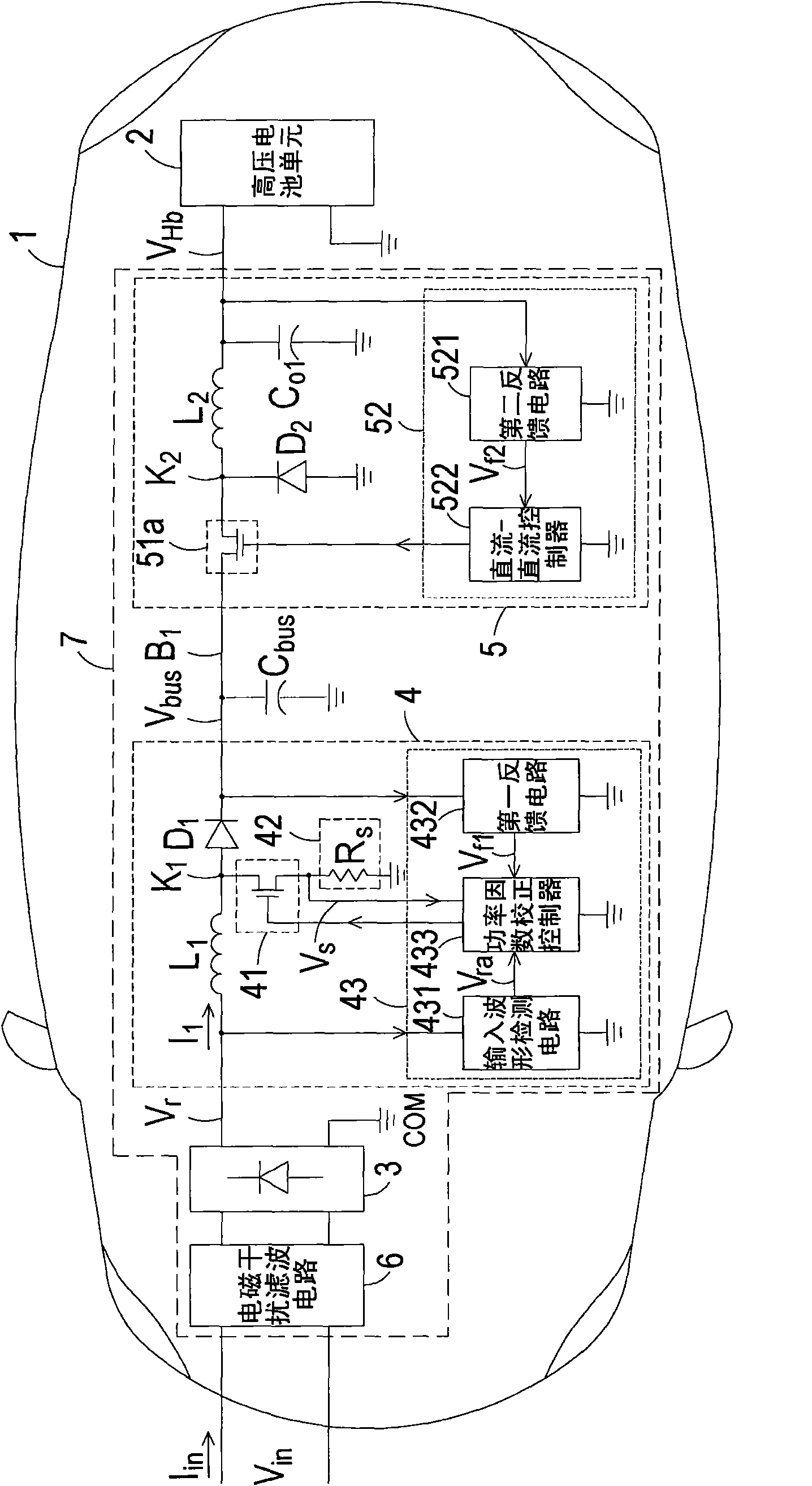

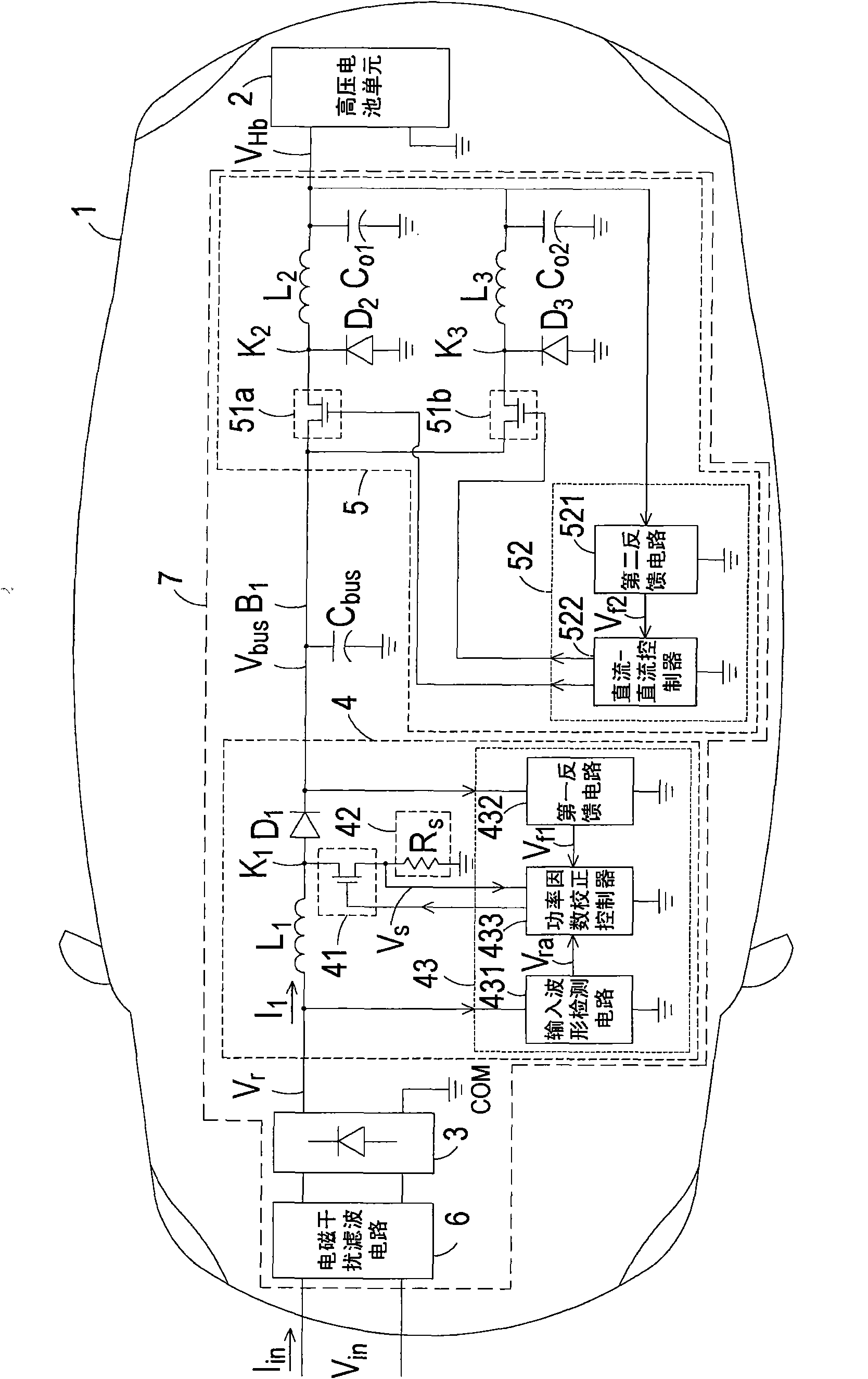

[0037] see figure 1 , which is a schematic diagram of the structure of the high-voltage battery charging system for electric vehicles according to a preferred embodiment of the present invention. Such as figure 1 As shown, the architecture of the high-voltage battery charging system of the electric vehicle is set in the body 1 of the electric vehicle to receive the AC input voltage V in (mains power) to charge the high-voltage battery unit 2, which includes: a rectifier circuit 3, a power factor correction circuit 4 (Power Factor Corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com