Method for forming coil with flat coiling machine

A forming method and coil technology, applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc., can solve the problems of large equipment footprint, large dimensional tolerance, and high operating skills, and achieve small footprint and easy operation. Easy, high dimensional accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] winding rectangular coil

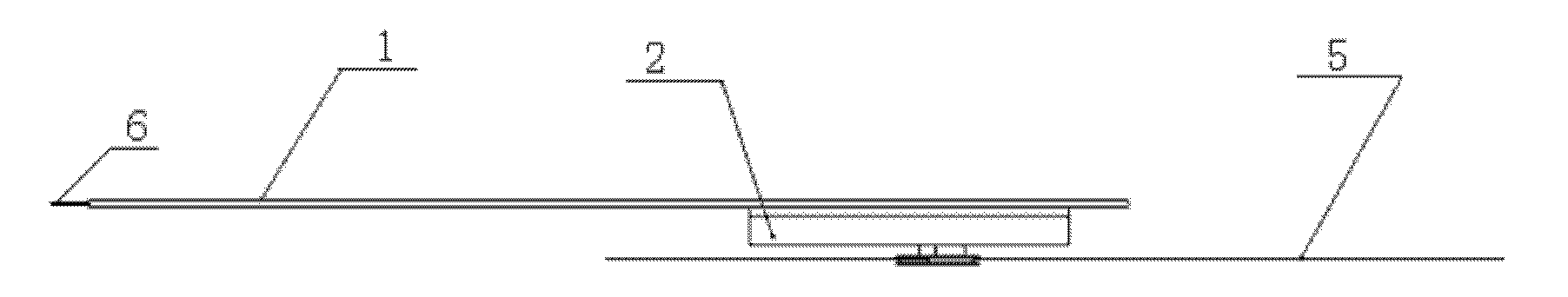

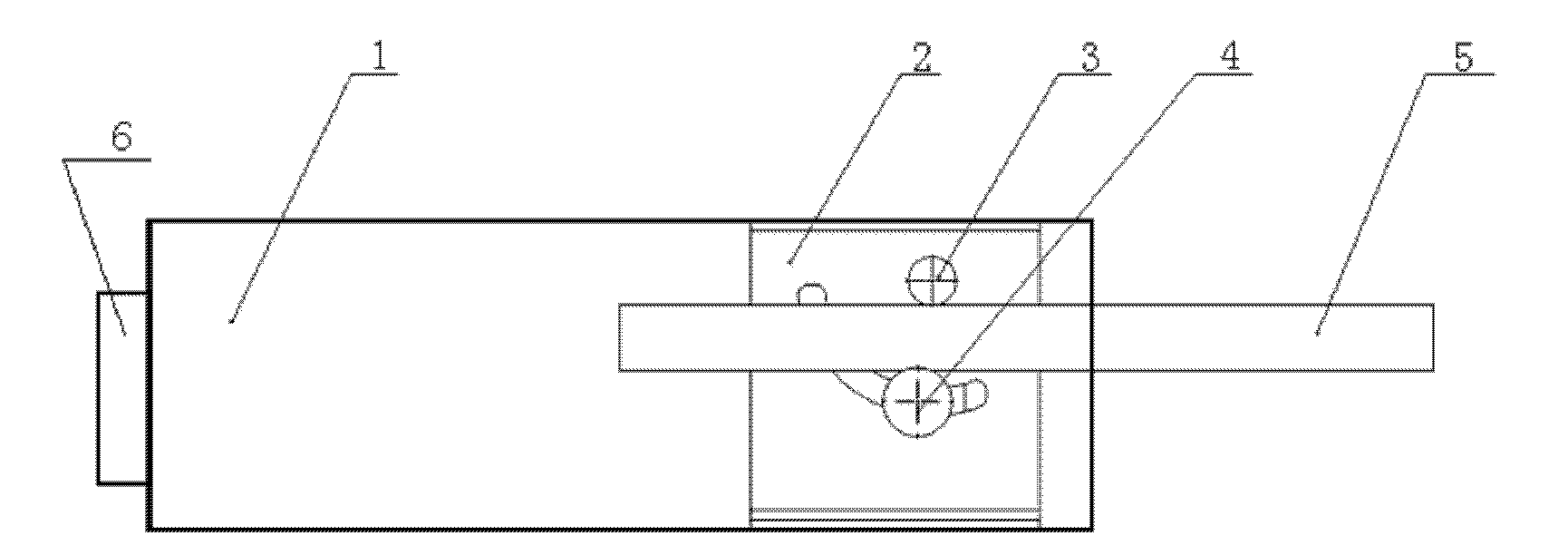

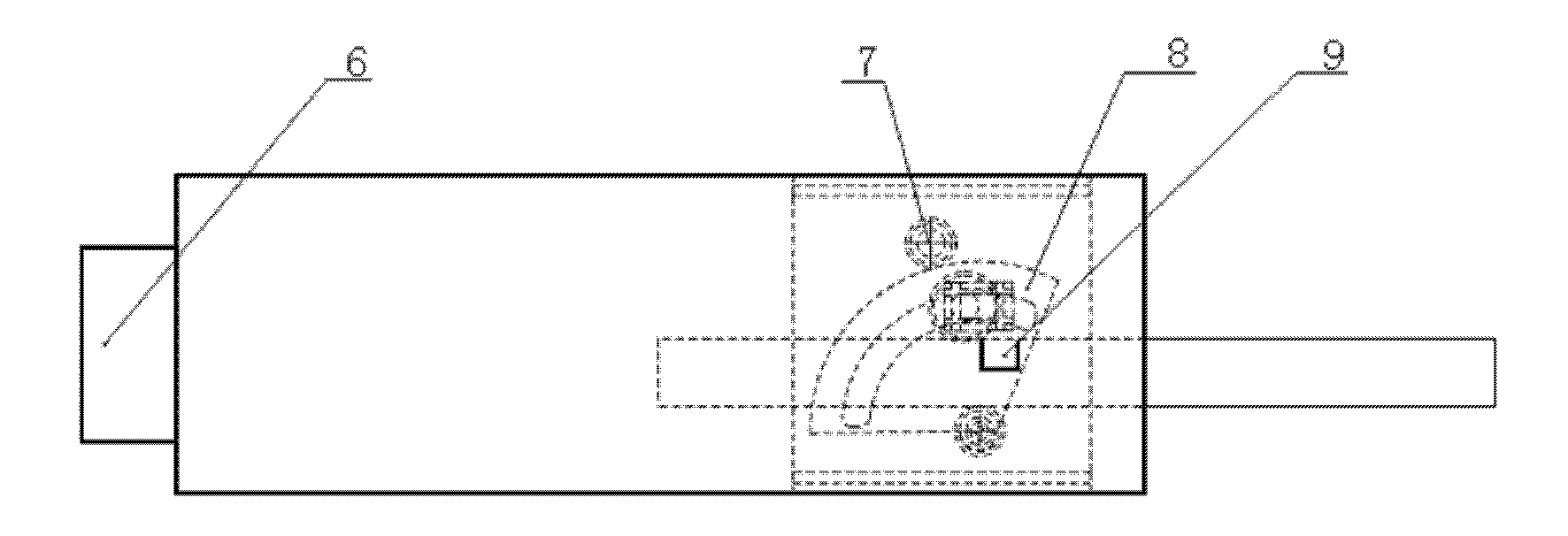

[0021] The coil edge-winding machine of the present invention is composed of a slide base 1 and a slide table 2 arranged on the slide base 1 . Slide table 2 is provided with slide table servo motor 6, corner wheel servo motor 9 with external gear 7, R angle guide wheel 3 and gear 8 with rounded corner roller 4, copper sheet 5 is placed on R angle guide wheel 3 and belt Between the fillet rollers 4; the slide servo motor 6 controls the movement of the slide 2 on the slide base 1, and the external gear 7 drives the gear 8 to make the fillet rollers rotate along the center of the R angle guide wheel to form the R angle of the coil.

[0022] Method of the present invention comprises the steps of following order:

[0023] Step 1: Set the length and width of the coil to be wound, the number of turns of the coil and the width of the copper sheet 5;

[0024] The second step: according to the width of the coil, set the stroke of the sliding table 2 a...

Embodiment 2

[0032] Adopt the method of the present invention, other steps are the same, only need to adjust the center-to-center distance of the rounded roller 4 and the R-angle guide wheel 3, can wind the coil of tower shape, ellipse and irregular shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com