High-temperature resistant and radiation-resistant inorganic insulating hollow cable as well as manufacturing method and mold thereof

An inorganic insulation and radiation-resistant technology, applied in the direction of insulated cables, insulated conductors, rigid tube cables, etc., can solve the problems of unusable, low ambient temperature, and poor temperature control effect, and achieve the effect of good electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

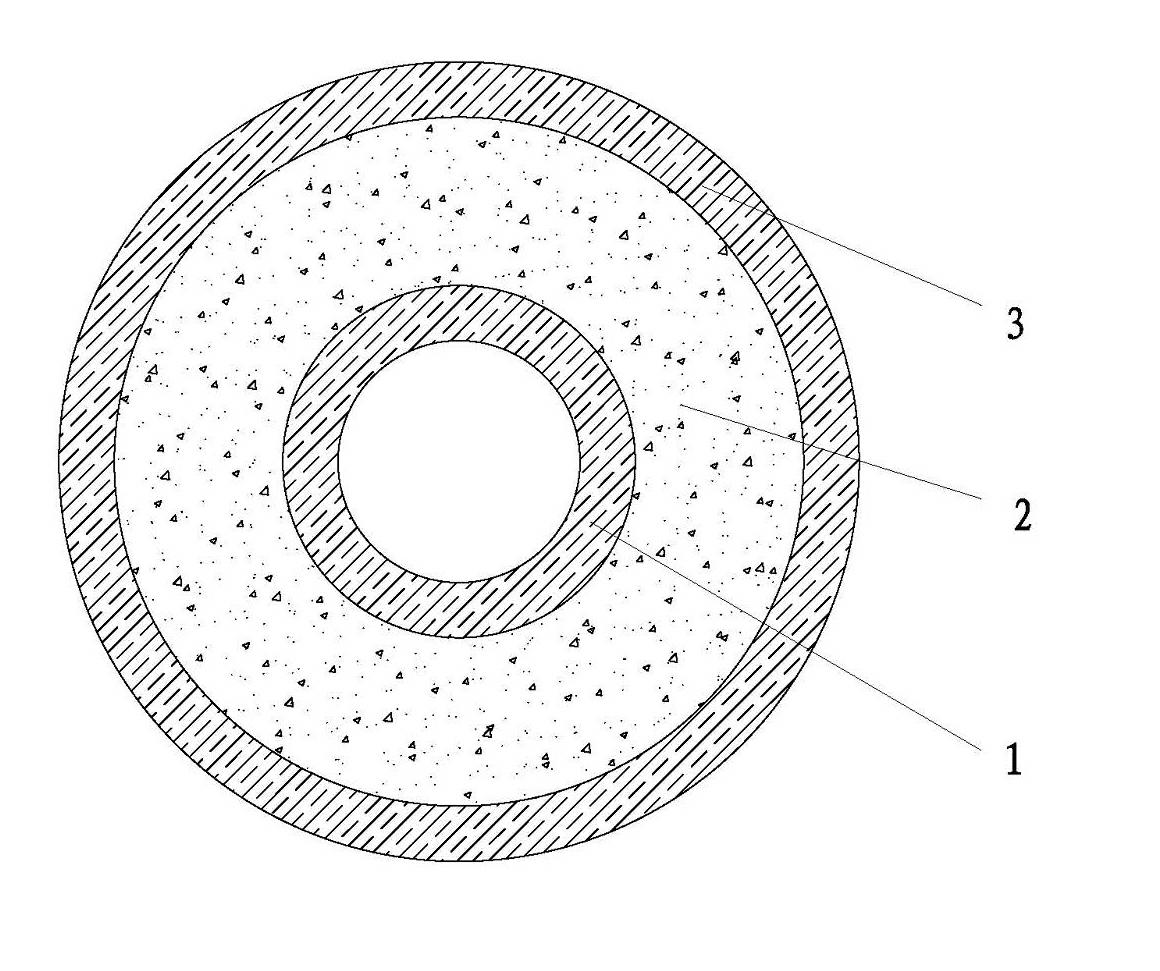

[0034] Such as figure 1 As shown, the high temperature and radiation resistant inorganic insulated hollow cable is composed of a conductor 1, an insulating layer 2 and a sheath layer 3 in sequence from the inside to the outside. The conductor 1 is a single-layer hollow seamless copper tube, the insulating layer 2 is a magnesium oxide insulating layer, and the sheath layer 3 is a stainless steel tube.

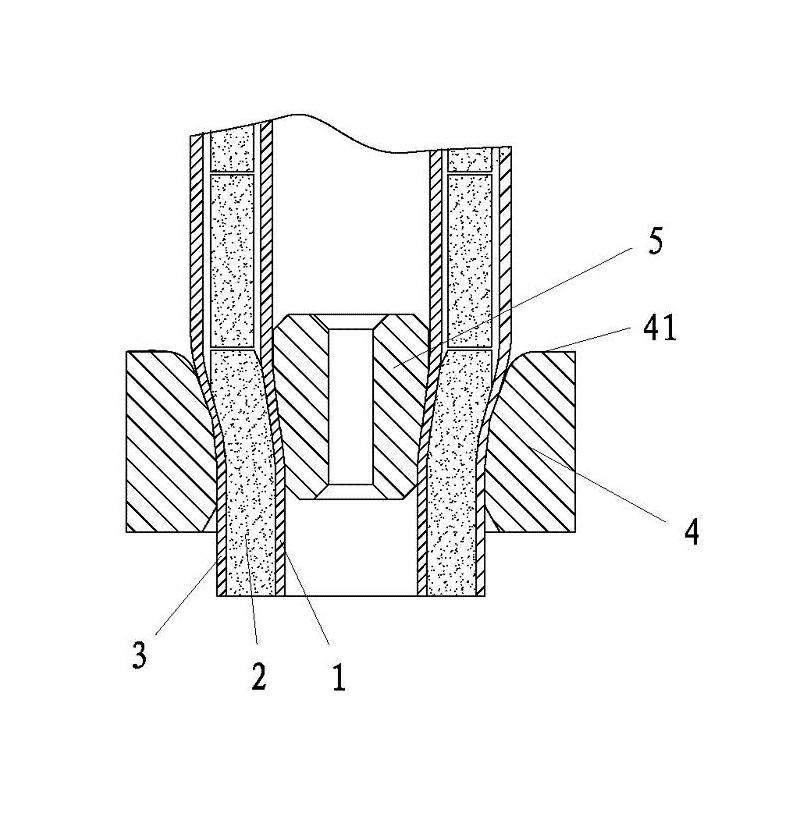

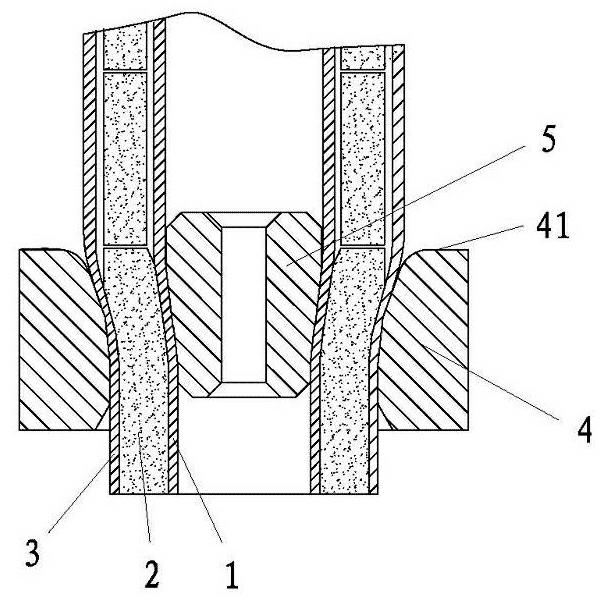

[0035] Such as figure 2 Shown, a kind of mold that is used to manufacture above-mentioned cable, it comprises annular outer mold 4 and cylindrical inner mold 5, and the inner edge of the entrance of said outer mold is an inclined plane, and this inclined plane and outer mold edge mouth plane 41 The included angle is 108°, and the slope is connected with the outer mold edge plane 41 with a smooth transition of an arc; the inner mold 5 is matched with the outer mold 4 and free from the outer mold 4, and the inner mold 5 is cylindrical The two ends have different diameters and a...

Embodiment 2

[0052] Such as figure 1 As shown, the high temperature and radiation resistant inorganic insulated hollow cable is composed of a conductor 1, an insulating layer 2 and a sheath layer 3 in sequence from the inside to the outside. The conductor 1 is a pure nickel tube, the insulating layer 2 is an alumina insulating layer, and the sheath layer 3 is a stainless steel tube.

[0053] Such as figure 2 Shown, a kind of mold that is used to manufacture above-mentioned cable, it comprises annular outer mold 4 and cylindrical inner mold 5, and the inner edge of the entrance of said outer mold is an inclined plane, and this inclined plane and outer mold edge mouth plane 41 The included angle is 112°, and the inclined plane is connected with the outer mold edge plane 41 with an arc smooth transition; the inner mold 5 is matched with the outer mold 4 and is free from the outer mold 4, and the inner mold 5 is cylindrical The slopes with different diameters at both ends and a 7° slope tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com