Characteristic testing system of semiconductor laser

A characteristic test and laser technology, which is applied in the direction of semiconductor laser, single semiconductor device test, laser, etc., can solve the problem of not having the functions of polarization test, near-field nonlinear test and spatial spectrum test, low test power, and unable to realize test functions at the same time and other problems, to achieve the effect of facilitating large-scale detection applications, realizing accurate measurement, and realizing automatic continuous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

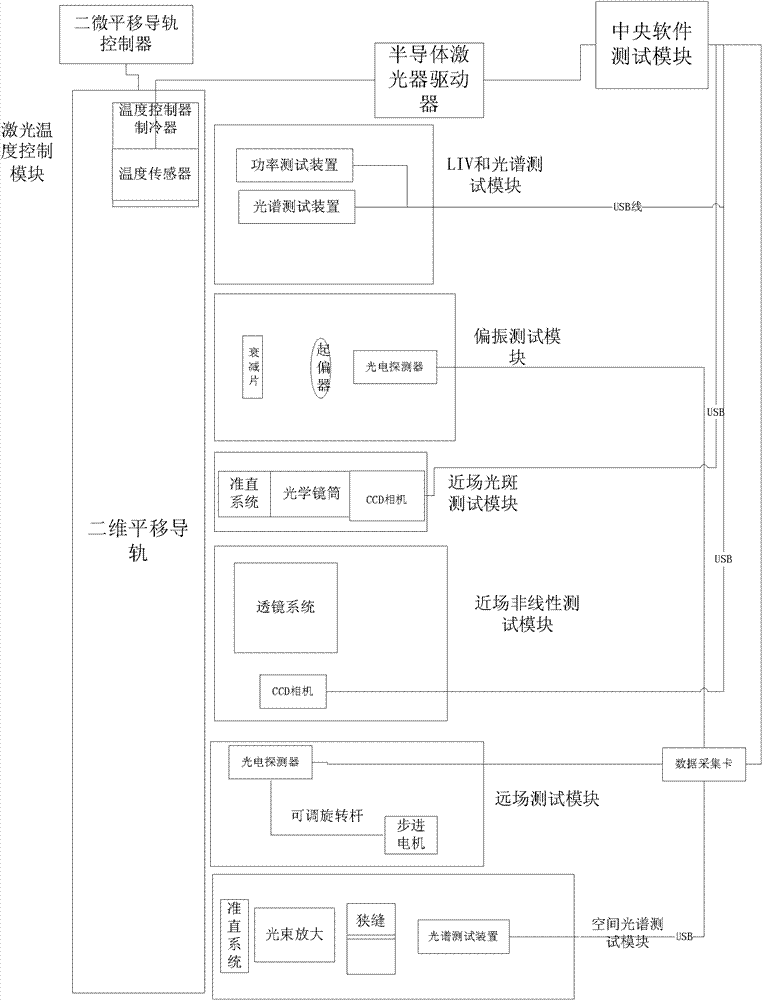

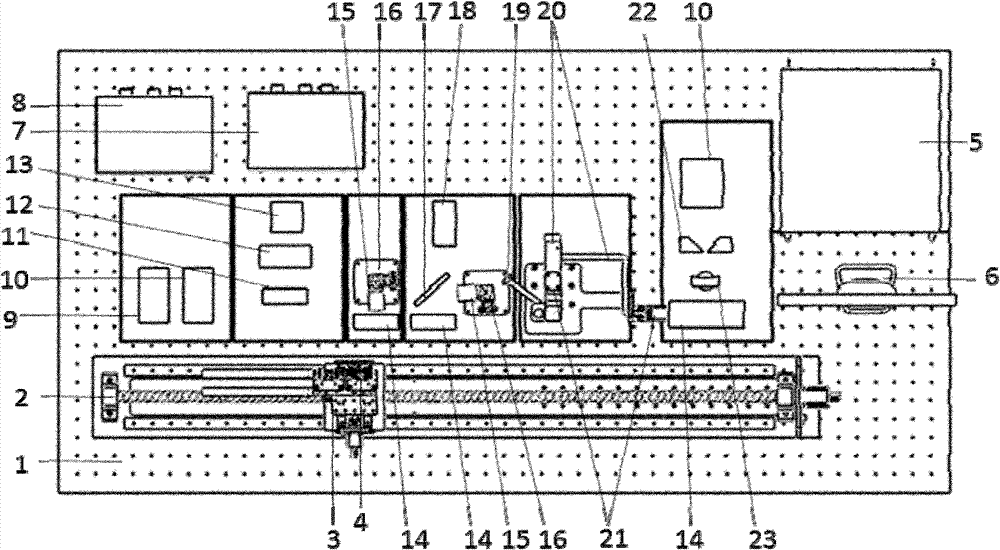

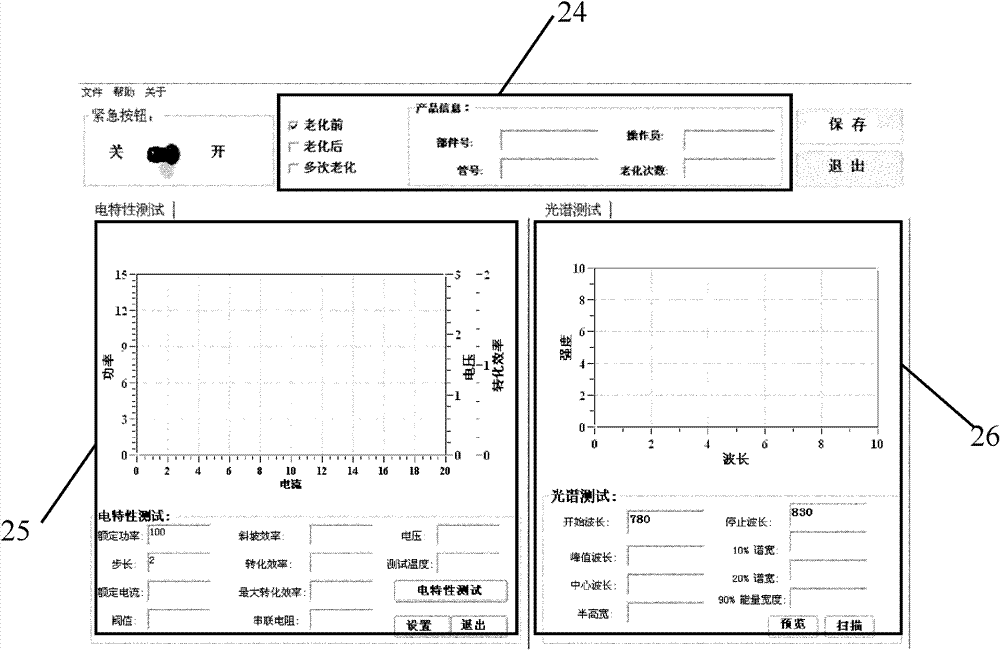

[0032] see figure 1 and figure 2 , the semiconductor laser characteristic testing system of the present invention comprises an optical platform 1 and a computer system, wherein the optical platform 1 is fixedly provided with a two-dimensional translation guide rail 2, and the two-dimensional translation guide rail 2 is fixedly provided with a laser fixing seat through a slider, and the laser is fixed The test laser 4 is arranged on the seat, and the laser temperature control module for controlling the temperature of the test laser 4 is also provided on the laser fixing seat. The LIV and spectrum test modules connected to the computer system are arranged on the side of the two-dimensional translation guide rail 2, respectively. Polarization test module, near-field spot test module, near-field nonlinear test module, far-field test module and spatial spectrum test modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com