Full-automatic computerized flat knitting machine

A flat knitting machine and full computer technology, applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of many components of the linkage mechanism, short life of the electromagnet, high manufacturing cost, etc., achieve high motion stability, improve The effect of weaving precision and simple structure

Inactive Publication Date: 2011-06-29

JIANGSU ZOJE MACHINERY TECH

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Linkage drives often use electromagnets and cams to drive and control the movable triangular mechanism, but the linkage mechanism has many components, relatively complex structure, high manufacturing cost, complicated operation and prone to failure. In addition, the life of the electromagnet is short and easy cause noise pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

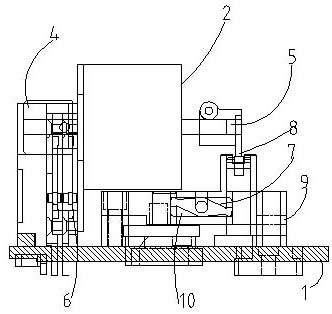

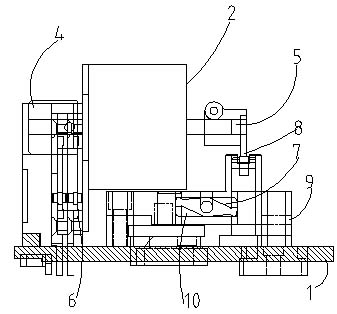

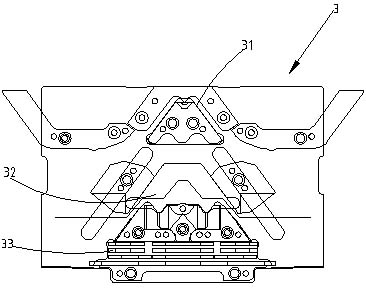

The invention discloses a full-automatic computerized flat knitting machine, which comprises a hill-shaped plate, a fixed seat arranged above the hill-shaped plate, a triangle mechanism arranged on the fixed seat, and a step motor arranged above the fixed seat, wherein the triangle mechanism comprises a turning-needle triangle moving up and down, a pressing-needle triangle, and a knitting triangle moving in a direction opposite to the moving direction of the turning-needle triangle; two ends of the output shaft of the step motor are respectively provided with a gear and a cam; the gear is in transmission connection with the pressing-needle triangle through a rack; and the cam drives the turning-needle triangle and the knitting triangle to move up and down through a lever rotationally arranged on the fixed seat. The full-automatic computerized flat knitting machine is reasonable in design and simple in structure; a plurality of actions of the triangle mechanism are controlled by one step motor; the transmission connection lines are concise and the combined drive is carried out according to movement relations of the triangles; the movement stability is high; the lifting speed of the triangle mechanism is greatly improved; and the positioning accuracy of various triangles is improved, so that the work efficiency and the knitting accuracy of the flat knitting machine are improved, and the fabric knitting quality is improved further.

Description

A fully computerized flat knitting machine technical field The invention relates to a fully computerized flat knitting machine, which belongs to the technical field of knitting machinery. Background technique On the fully computerized flat knitting machine, the cam mechanisms such as the transfer cam, the knitting cam and the pressing cam are movably embedded on the mountain board, and need to be driven by a corresponding driving mechanism. In the existing knitting mechanisms, some of these triangular mechanisms can be driven independently, and some can be driven in linkage according to the mutual kinematic relationship. Linkage drives often use electromagnets and cams to drive and control the movable triangular mechanism, but the linkage mechanism has many components, relatively complex structure, high manufacturing cost, complicated operation and prone to failure. In addition, the life of the electromagnet is short and easy cause noise pollution. Contents of the inven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D04B15/36

Inventor 吕正祥钱雪东

Owner JIANGSU ZOJE MACHINERY TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com