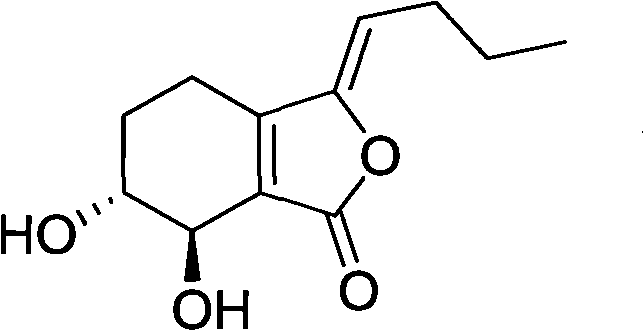

Method for preparing senkyunolide I from extract of Chinese angelica

A technology of angelica extract and ligusticolactone, which is applied in the field of preparation of lisanthemum lactone I, can solve the problems of cumbersome preparation methods and low yield, and achieve the effect of simplifying the preparation process and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1 Ligustilide I

[0021] Angelica decoction pieces 1kg, after removing impurities, pulverized into powder, the volume concentration is 95% ethanol 10L reflux extraction 2 times, each time 2 hours, combined extracts, recovered solvent to obtain about 200g of extract A.

[0022] Dilute the extract A to about 2000mL with deionized water (the concentration of the aqueous solution is equivalent to 0.5g·ml crude drug -1 ) and then put on HPD-100 macroporous resin column [the weight ratio of macroporous resin to raw medicinal material (danggui decoction pieces) is 0.3:1, the size of macroporous resin column is Φ150*1500mm], and the adsorption flow rate is 2BV h -1 , discard the eluent after eluting 6BV with deionized water, then elute 4BV with 50% ethanol with a volume concentration, collect the 50% ethanol eluate, and recover the solvent under reduced pressure to obtain about 30 g of extract B.

[0023] Disperse extract B with 100mL deionized wa...

Embodiment 2

[0026] The preparation of embodiment 2 Ligustilide I

[0027] Angelica decoction pieces 1kg, after removing impurities, pulverized into powder, the volume concentration is 95% ethanol 10L reflux extraction 2 times, each time 2 hours, combined extracts, recovered solvent to obtain about 200g of extract A.

[0028] Dilute the extract A to about 2000mL with deionized water (the concentration of the aqueous solution is equivalent to 0.5g·ml crude drug -1 ) on the HPD-100 macroporous resin column (the weight ratio of the macroporous resin to the original medicinal material is 0.3:1, the macroporous resin column specification Φ150*1500mm), and the adsorption flow rate is 1BV h -1 , discard the eluent after eluting 4BV with 10% ethanol, then elute 6BV with 40% ethanol with a volume concentration, collect the 40% ethanol eluate, reclaim the solvent under reduced pressure to obtain about 30 g of extract B.

[0029] Disperse extract B with 100mL deionized water (the concentration of th...

Embodiment 3

[0032] The preparation of embodiment 3 Ligustilide I

[0033] Angelica decoction pieces 1kg, after removing impurities, pulverized into powder, the volume concentration is 50% ethanol 10L reflux extraction 2 times, each time 2 hours, the extracts were combined, and the solvent was recovered to obtain about 200g of extract A.

[0034] Dilute extract A to about 1250mL with deionized water (the concentration of this aqueous solution is equivalent to crude drug 0.8g·ml-1 ) on the HPD-100 macroporous resin column (the weight ratio of the macroporous resin to the original medicinal material is 0.4:1, the macroporous resin column specification Φ150*1500mm), and the adsorption flow rate is 1.5BV h -1 , with a volume concentration of 5% ethanol to elute 5BV and then discard the eluent, then use a volume concentration of 45% ethanol to elute 5BV, collect the 45% ethanol eluate, reclaim the solvent under reduced pressure to obtain about 30g of extract B.

[0035] Disperse the extract B w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com