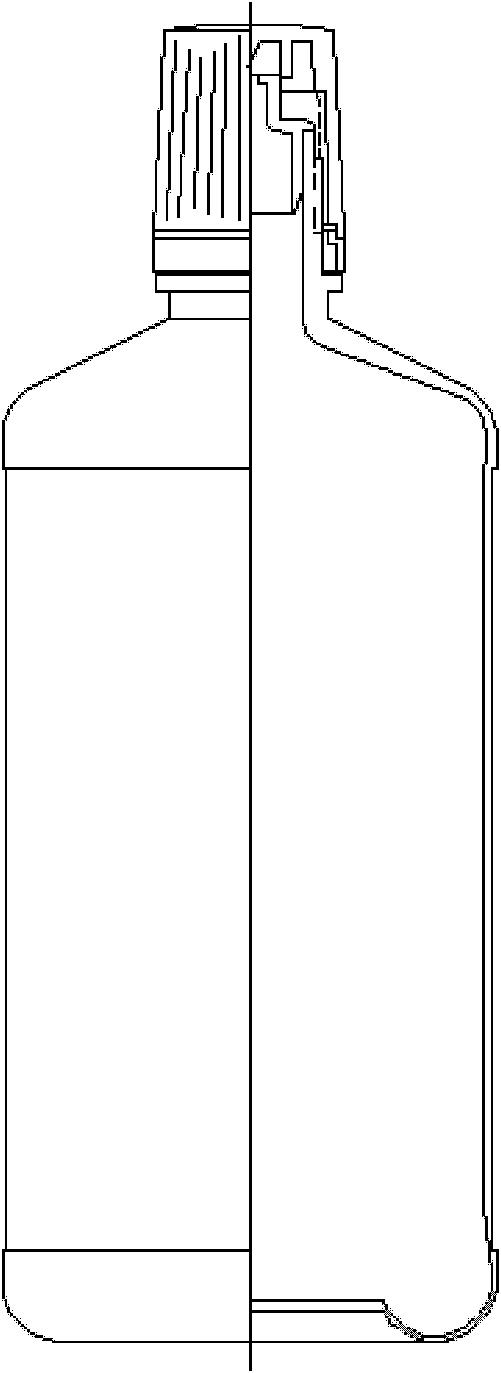

Container for preventing microbial contamination after contact lens care solution is unsealed and preparation method thereof

A technology for preventing microbial contamination and contact, which is applied in the direction of capping with auxiliary devices, sealing parts with auxiliary devices, closing, etc., which can solve the problems of nursing solution pollution and achieve the effect of uncomplicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

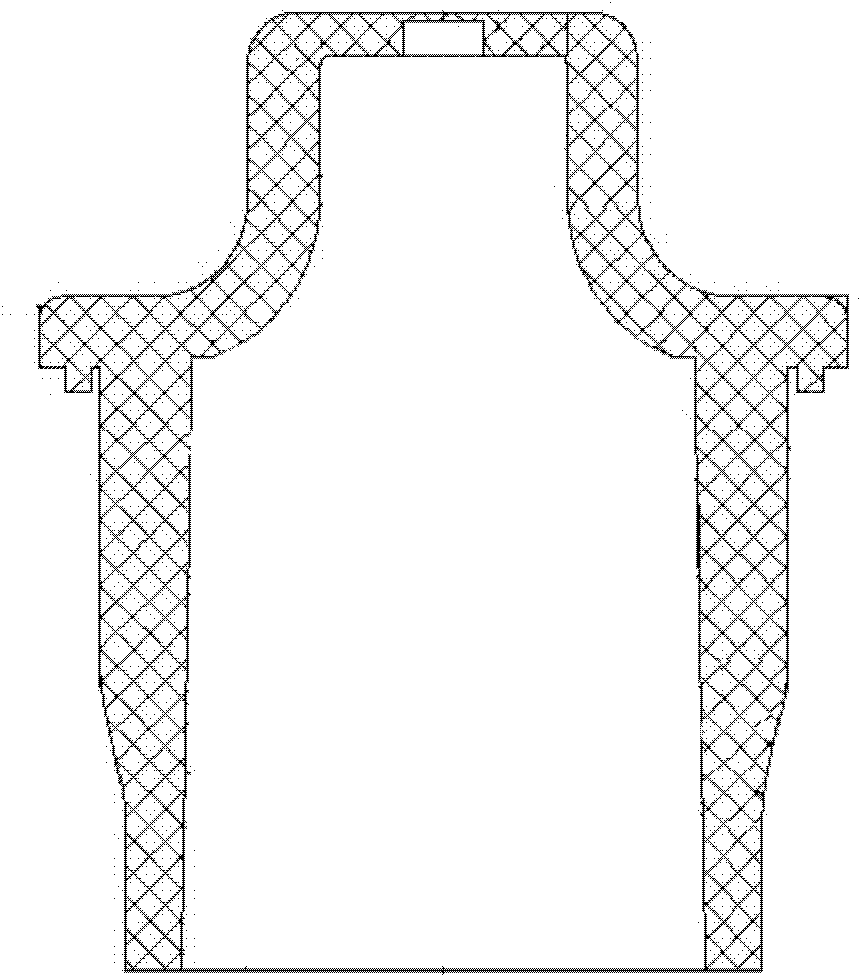

Method used

Image

Examples

Embodiment 1

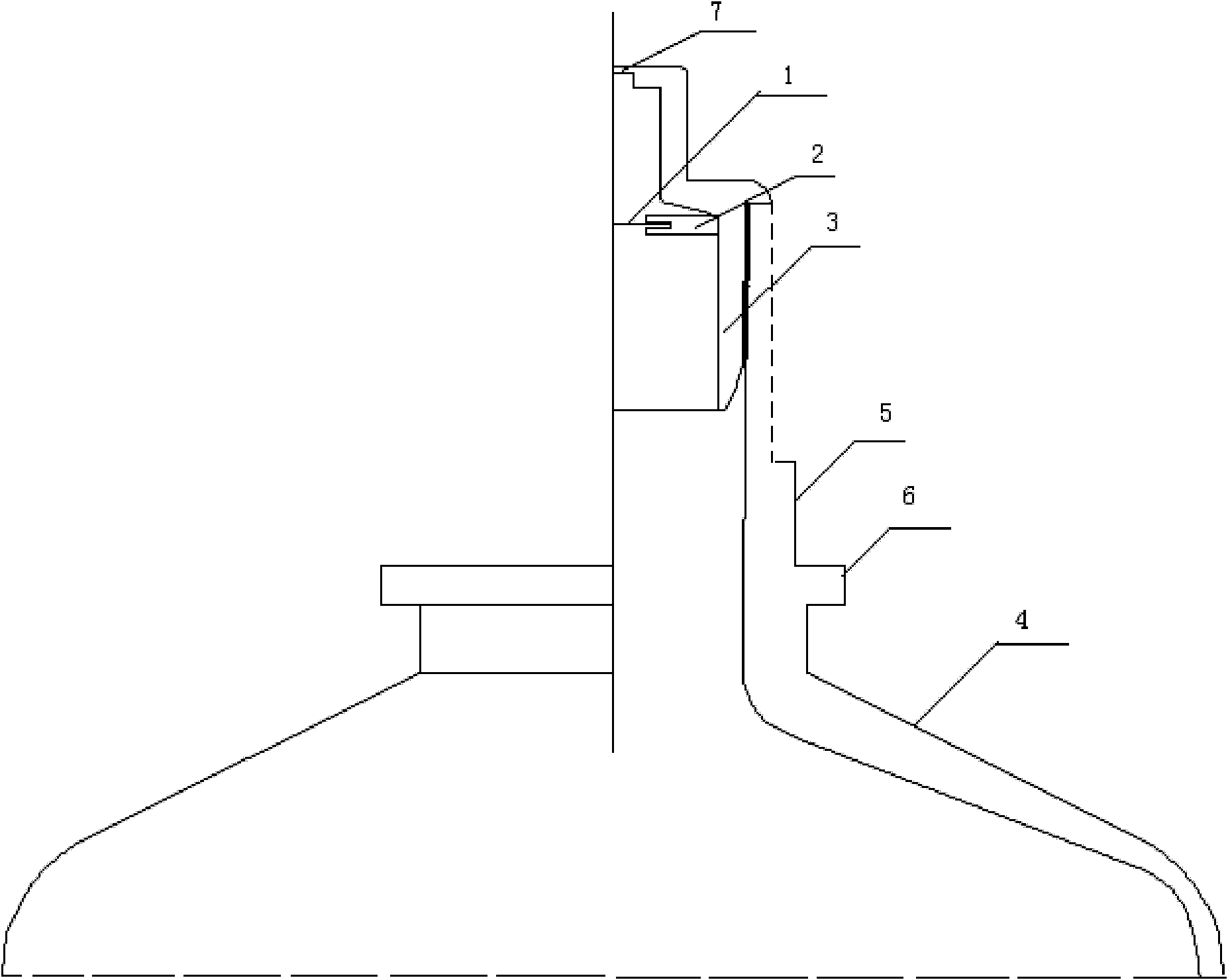

[0034] the above Figure 3-5 The preparation method of the container for preventing microbial contamination after the contact lens care solution is unsealed comprises the steps:

[0035] (1) Container processing and molding: fully mix the low-density polyethylene pellets and high-density polyethylene materials at a mass ratio of 70:30, and then pour them into the barrel of the blow molding machine (Yexing SYC-45). The blow molding process is carried out according to the following blow molding process conditions: ①Plasticizing temperature: the temperature of main barrel 1 is controlled at 168°C, and the temperature of main barrel 2 and main barrel 3 is controlled at 172°C; ②The temperature of the die head is controlled at 175°C; ③Molding unit The cycle time is 20Sec.

[0036] (2) Fabrication of the surrounding sterilizing filter membrane with low-density polyethylene: the polyvinylidene fluoride fiber membrane (Millipore Company) with a thickness of 0.15 mm and a 0.45 μm pore ...

Embodiment 2

[0044] The preparation method of the container that prevents contact lens care solution from being contaminated by microorganisms after unsealing comprises the steps:

[0045] (1) Container processing and molding: fully mix the low-density polyethylene pellets and high-density polyethylene materials at a mass ratio of 70:30, and then pour them into the barrel of the blow molding machine (Yexing SYC-45). The blow molding process is carried out according to the following blow molding process conditions: ①Plasticizing temperature: the temperature of main barrel 1 is controlled at 168°C, and the temperature of main barrel 2 and main barrel 3 is controlled at 175°C; ②The temperature of the die head is controlled at 175°C; ③Molding unit The cycle time is 20Sec.

[0046] (2) Fabrication of the surrounding sterilizing filter membrane with low-density polyethylene: a polyvinylidene fluoride fiber membrane (Millipore Company) with a thickness of 0.15 mm and a 0.45 μm pore size of the st...

Embodiment 3

[0054] The preparation method of the container that prevents contact lens care solution from being contaminated by microorganisms after unsealing comprises the steps:

[0055] (1) Container processing and molding: fully mix the low-density polyethylene pellets and high-density polyethylene materials at a mass ratio of 70:30, and then pour them into the barrel of the blow molding machine (Yexing SYC-45). The blow molding process is carried out according to the following blow molding process conditions: ①Plasticizing temperature: the temperature of main barrel 1 is controlled at 168°C, and the temperature of main barrel 2 and main barrel 3 is controlled at 172°C; ②The temperature of the die head is controlled at 175°C; ③Molding unit The cycle time is 20Sec.

[0056] (2) Fabrication of the sterilizing filter membrane with low-density polyethylene surroundings: the polyethersulfone (Millipore Company) membrane with a thickness of 0.15mm and a 0.45 μm pore size of the sterilizing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com