Seed crystal cutting machine

A cutting machine and seed crystal technology, applied in stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems of low efficiency of removing seed crystals, harsh working environment, etc., and achieve the goal of improving efficiency, reducing environmental pollution, and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

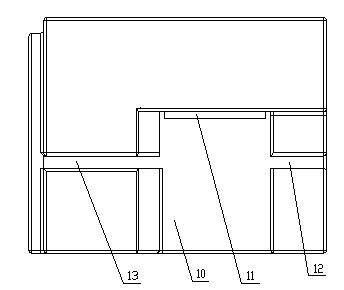

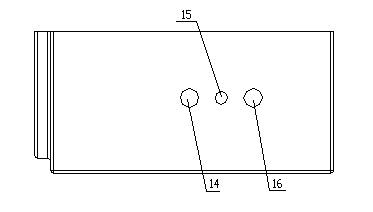

[0023] In conjunction with the accompanying drawings, the present invention mainly relates to the feed device of the multi-knife cutting machine. First, the cam handle 1 is used to drive the cam 2 to rotate, and the positioning cylinder 3 on the cam 2 is connected to the connecting rod 6 by the bolt 4, and the slider is connected by the bolt 5. 7 is connected with the connecting rod 6, and the concave surface module 8 on the slide block is used to clamp the sticky wafer to carry out the excision of the seed crystal. Place the wafer on the reference plane 10, adjust the position of the x-axis reference movable block 11 through bolts 14, 15, 16, so that the seed crystal part is aligned with the grinding wheel blade.

[0024] The following describes the engineering process of the present invention in conjunction with the accompanying drawings: first, the seed crystal of the sticky mound is placed on the reference plane 10 to fix the z-axis direction, and then the tool setting is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com