Compound ceftiofur sodium freeze-dried power injection used for injection

A technology of ceftiofur sodium and freeze-dried powder injection, which is applied in the field of compound ceftiofur sodium freeze-dried preparations for injection, can solve the problems of bacterial drug resistance and high cost, and achieve the purpose of inhibiting the rise of body temperature and PGF-A concentration , reduce drug resistance, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Control the temperature at 10±5°C, add 1 part by weight of sulbactam sodium and 1 part by weight of flunixin meglumine into a sterile container, add water for injection to 85% of the total amount, and turn on the vacuum (to make the system slightly negative). pressure), stir to dissolve, then add 2 parts by weight of ceftiofur sodium to the above solution, turn on the vacuum, stir to dissolve, adjust the pH value to 4.5-6.5, add water for injection to the full amount, and stir evenly.

[0019] Sampling was taken to determine the pH value and the content of ceftiofur sodium, sulbactam sodium, and flunixin meglumine. After the test indicators were qualified, it was first filtered with a 0.45 μm cellulose filter, and then filtered with a 0.22 μm cellulose filter. Remove impurities.

[0020] The filtered filtrate is divided into control glass bottles, half-stopped, and vacuum freeze-dried to obtain the compound ceftiofur sodium freeze-dried powder injection of the present i...

Embodiment 2

[0022] Control the temperature at 10±5°C, add 4 parts by weight of ceftiofur sodium into a sterile container, add water for injection to 85% of the total amount, turn on the vacuum, stir to dissolve, and then add 1 part by weight of sulbactam sodium and 1 Add the flunixin meglumine in parts by weight to the above solution, turn on the vacuum, stir to dissolve, adjust the pH value to 4.5-6.5, add water for injection to the full amount, and stir evenly.

[0023] Sampling was taken to determine the pH value and the content of ceftiofur sodium, sulbactam sodium, and flunixin meglumine. After the test indicators were qualified, it was first filtered with a 0.45 μm cellulose filter, and then filtered with a 0.22 μm cellulose filter. Remove impurities.

[0024] The filtered filtrate was divided into control glass bottles, half-stopped, and vacuum freeze-dried to obtain the compound ceftiofur sodium / sulbactam sodium freeze-dried powder of the present invention.

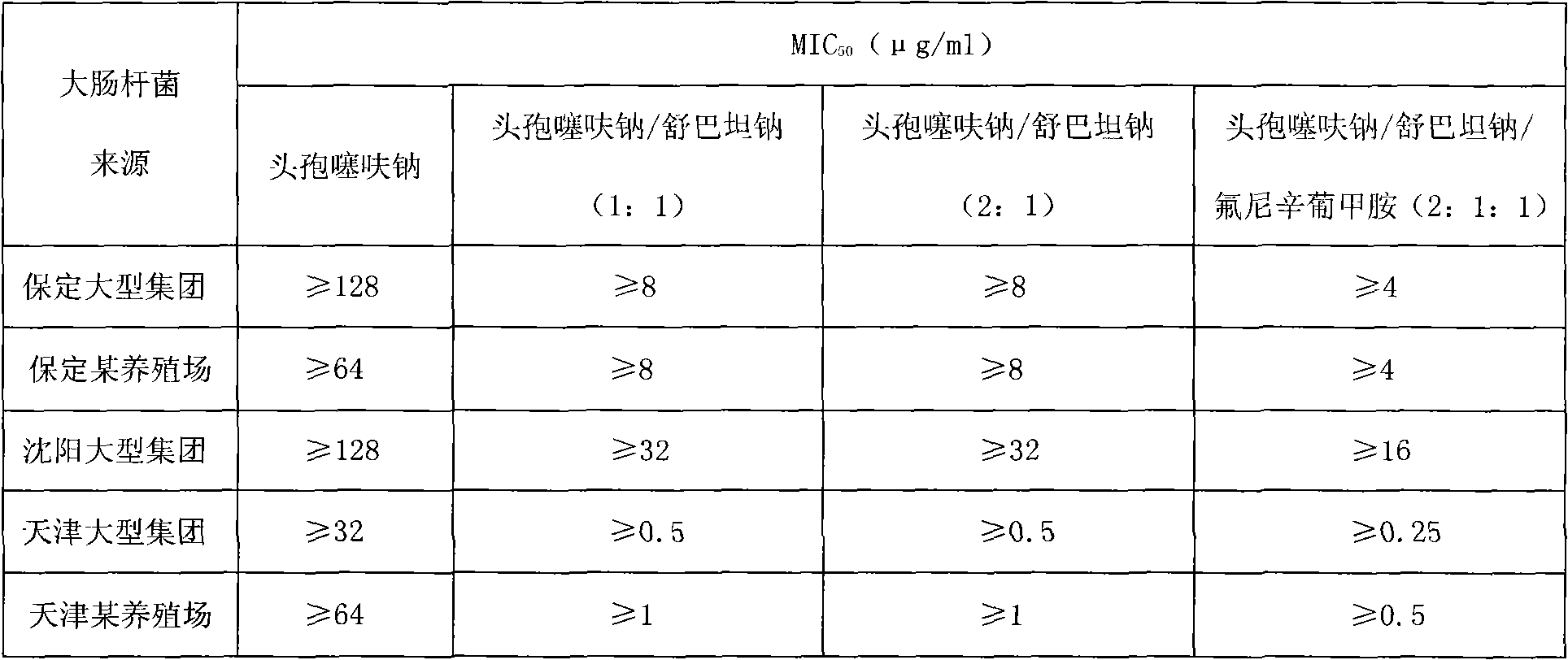

[0025] For the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com