Brake lining for a disc brake and brake lining system

A technology of disc brakes and brake linings, applied in the direction of brake components, brake types, gear transmission mechanisms, etc., can solve the problems of disturbing brake noise, uneven distribution of brake bands, and increased wear, and achieve small wear , weight saving, high shape stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

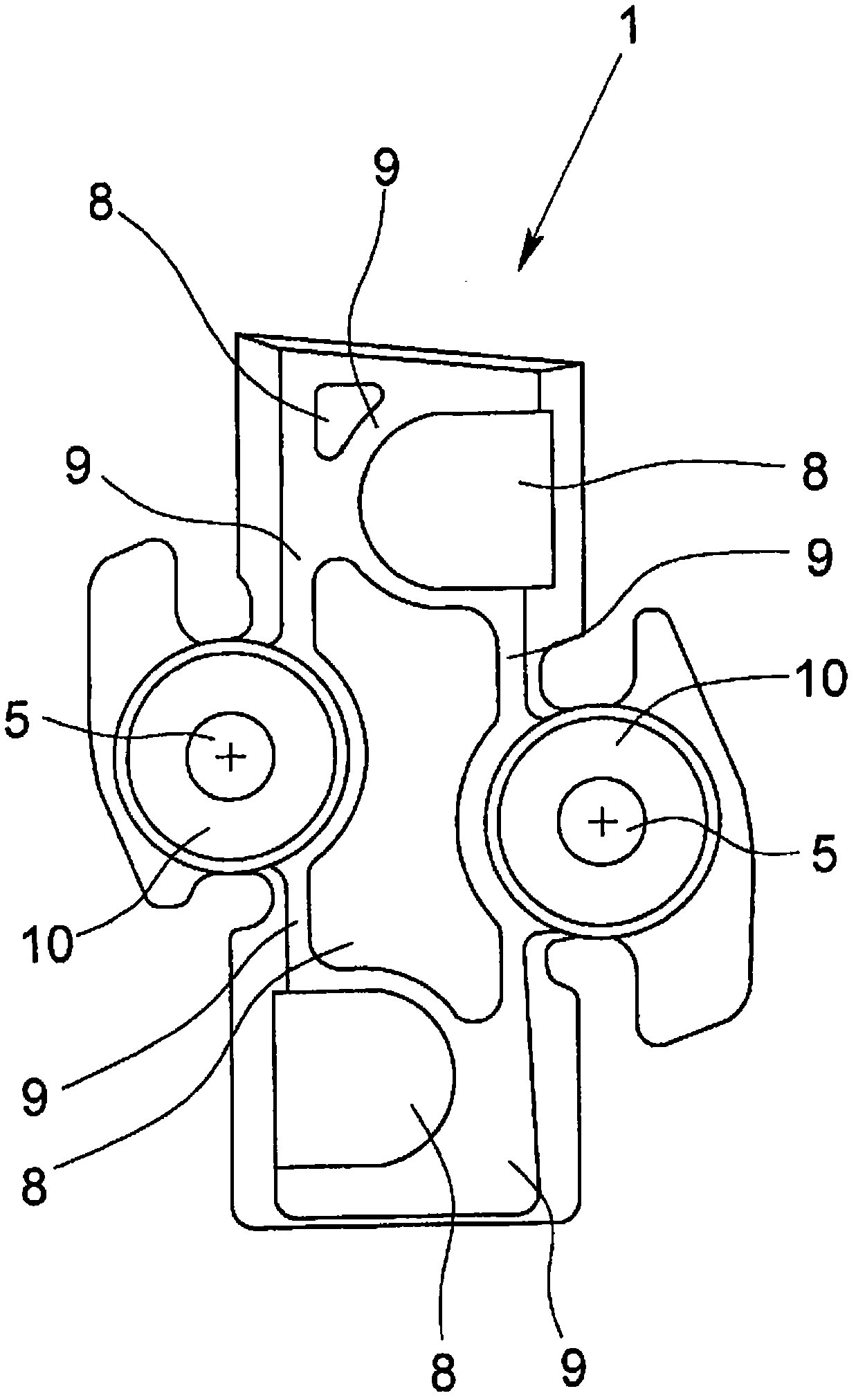

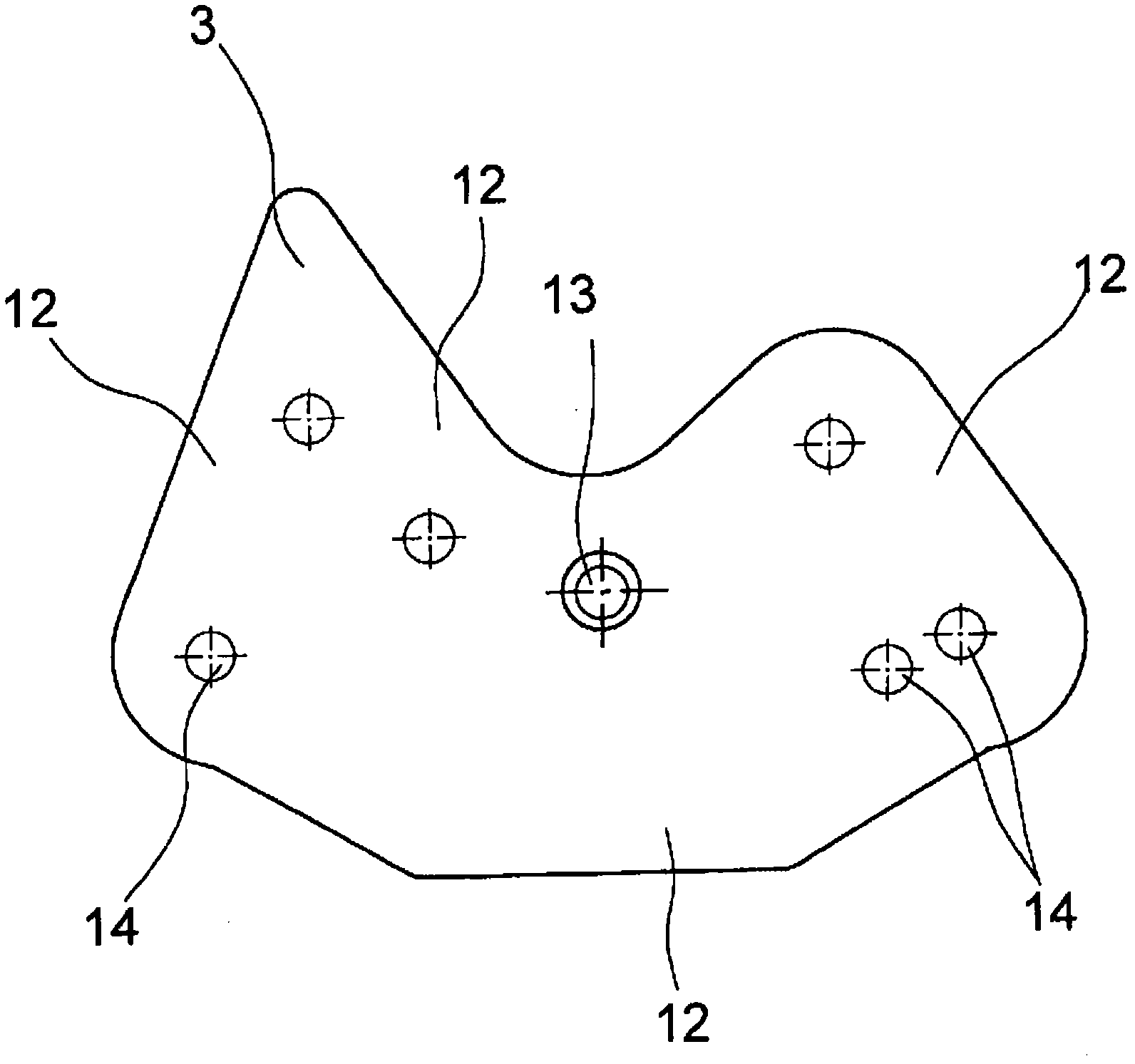

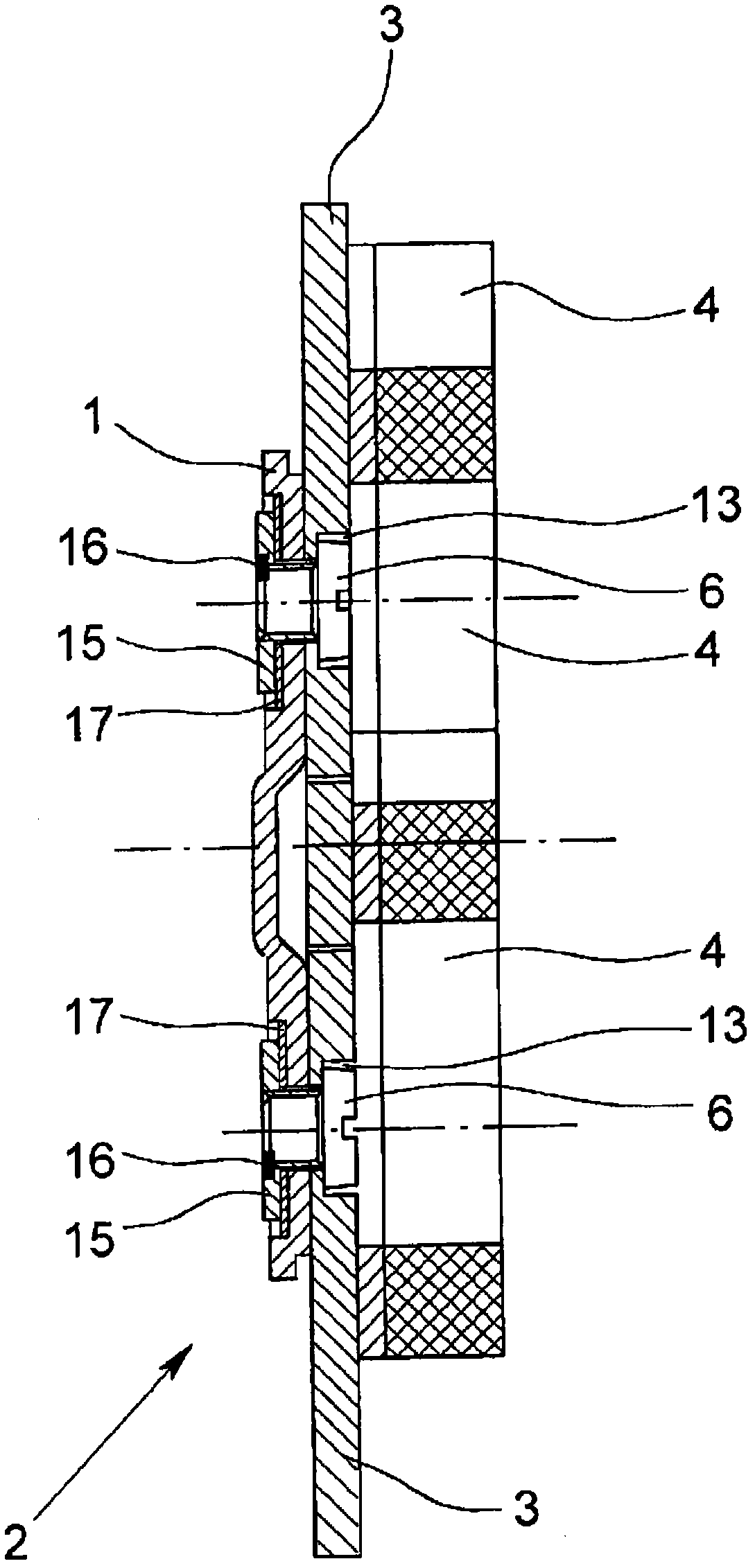

[0035] figure 1 shown for disc brakes for vehicles not shown image 3 A plan view of a back part 1 configured as a casting for a brake lining 2 shown in , wherein the back part 1 is provided for use with two figure 2The carrier plate 3 shown in is fixed, and wherein a plurality of friction segments 4 are fixed at the carrier plate 3, which is especially shown in Figure 5 middle. The back part 1 is made of malleable cast iron and is distinguished by its high thermal conductivity. In addition, the back part 1 has high strength and stability under mechanical loads.

[0036] For the fastening of the carrier plate 3, the back part 1 has two holding holes 5, which are provided for receiving image 3 with 5 The holding element 6 shown in , wherein each carrier plate 3 is held or fixed in a non-lost manner (unverlierbar) at the back part 1 by means of a holding element 6 . The holding element 6 can be a screw, which prevents loss after the carrier plate 3 has been fastened on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com