Single-stage boost inverter

An inverter, single-stage technology, applied in the field of new energy power generation inverters, can solve the problems that the devices cannot be turned on at the same time, increase the system cost, and reduce the conversion efficiency.

Inactive Publication Date: 2013-05-29

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For DC / AC power conversion applications with low DC voltage and higher AC output voltage, an additional DC / DC boost converter is required. This additional power conversion stage increases the cost of the system and reduces the conversion efficiency.

[0005] (3) The upper and lower devices of each bridge arm cannot be turned on at the same time, whether it is intentional or caused by electromagnetic interference, otherwise, a direct short circuit will occur and the device will be damaged

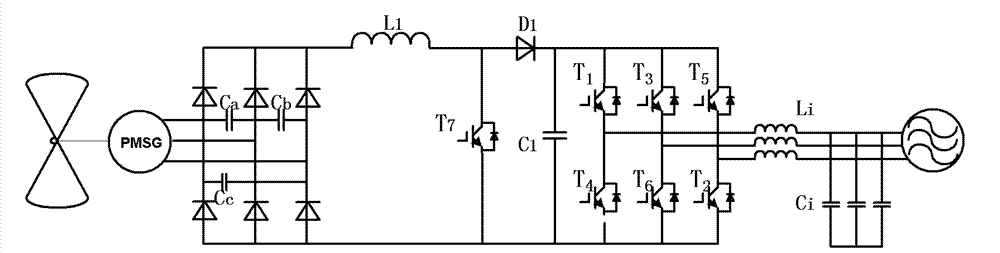

However, this topology inserts a first-stage Boost chopper circuit before the voltage-type grid-connected inverter, which increases the cost of the system, and the aforementioned shortcomings of the voltage-type inverter itself have not overcome

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

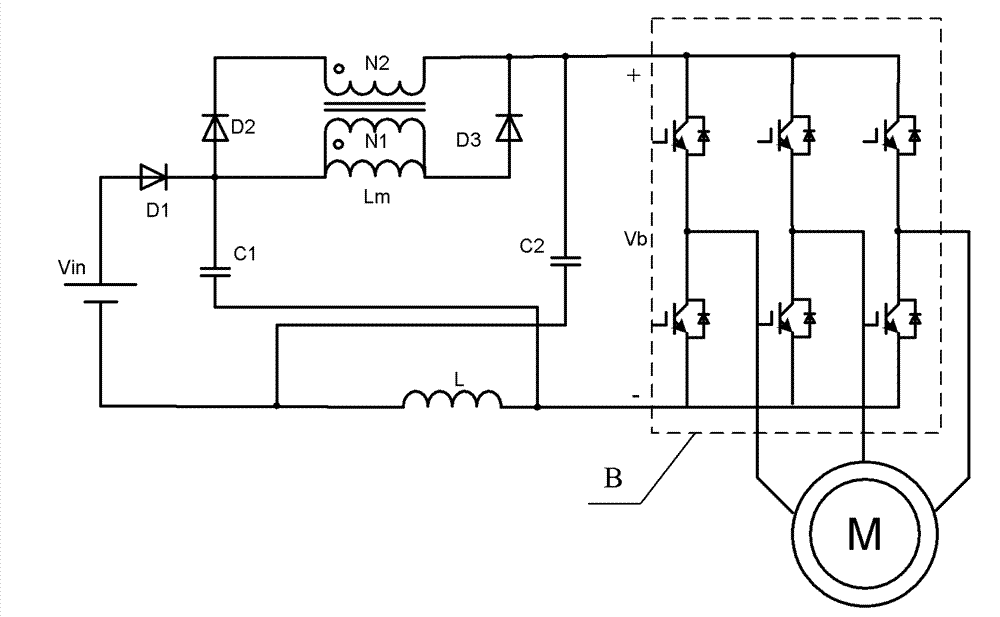

[0023] as attached image 3 As shown, the single-stage boost inverter topology of the present invention adds a boost network composed of passive devices before the three-phase switching bridge B of the traditional voltage-type inverter: a primary and secondary windings are tightly coupled and N1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a single-stage boost inverter, which comprises a coupling inductor of which a primary secondary-side winding is tightly coupled and N1 is smaller than N2; one end of an excitation inductor is connected with the cathode of a first diode, the anode of a second diode, and one end of a first capacitor, and the other end of the first capacitor is connected with the anode of a third diode; the anode of the first diode is connected with the anode of a power supply; the cathode of the second diode is connected to one end of a secondary-side winding of the coupling inductor; the other end of the secondary-side winding is connected with the cathode of the third diode and the direct current (DC) bus positive terminal of an inverter; one end of a second capacitor is connected with the DC bus positive terminal, and the other end of the second capacitor is connected with the cathode of the power supply; the other end of the first capacitor is connected with the DC bus negative terminal of the inverter and one end of the inductor, while the other end of the inductor is connected with the cathode of the power supply. By employing a shoot-through zero vector which is not allowed by a conventional inverter by the invention, the DC bus voltage of the inverter is boosted, the deficiency of a conventional voltage inverter is overcome, and the inverter is free from shoot-through phenomenon caused by electromagnetic interference, and is not needed to be inserted into a dead area.

Description

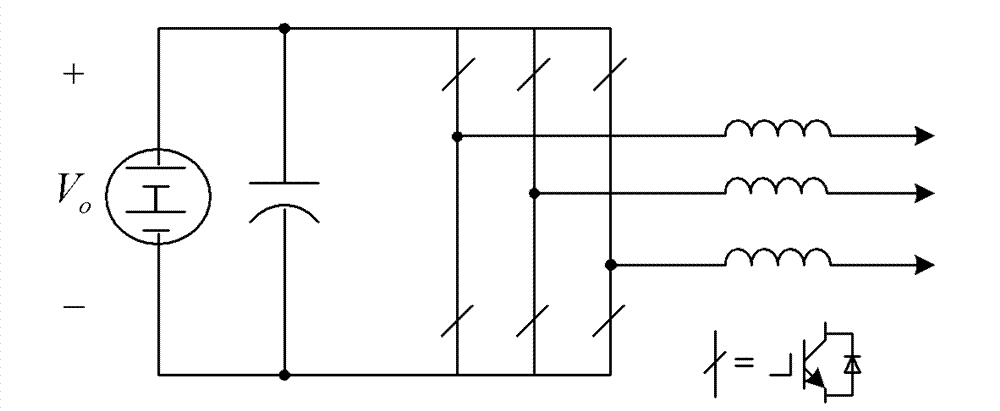

technical field [0001] The invention relates to a single-stage step-up inverter, which is especially suitable for a motor drive system in which a DC bus needs to be powered by a low-voltage step-up and a new energy power generation inverter adapting to a relatively large input voltage range. Background technique [0002] The traditional voltage source inverter inputs DC voltage and outputs AC voltage, and has a wide range of applications. The input DC voltage of the voltage source inverter can be obtained from the power grid or the rotating AC motor through rectification and filtering, and can also be obtained from batteries, fuel cells or photovoltaic cells, corresponding to general industrial applications (such as frequency converters), electric vehicles, renewable energy Distributed power generation and other occasions. In the voltage source inverter, due to the input DC voltage, the power semiconductor device is always kept forward biased, so the self-controlled forward...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02M7/521

Inventor 周玉斐黄文新

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com