Sealing structure for pole post and intermediate cover of storage battery

A technology of sealing structure and storage battery, applied in the direction of structural parts, battery pack parts, circuits, etc., can solve the problems of low pass rate, pole scratches, and inability to assemble, so as to improve pass rate and production efficiency, and reduce position tolerance Requirements, design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

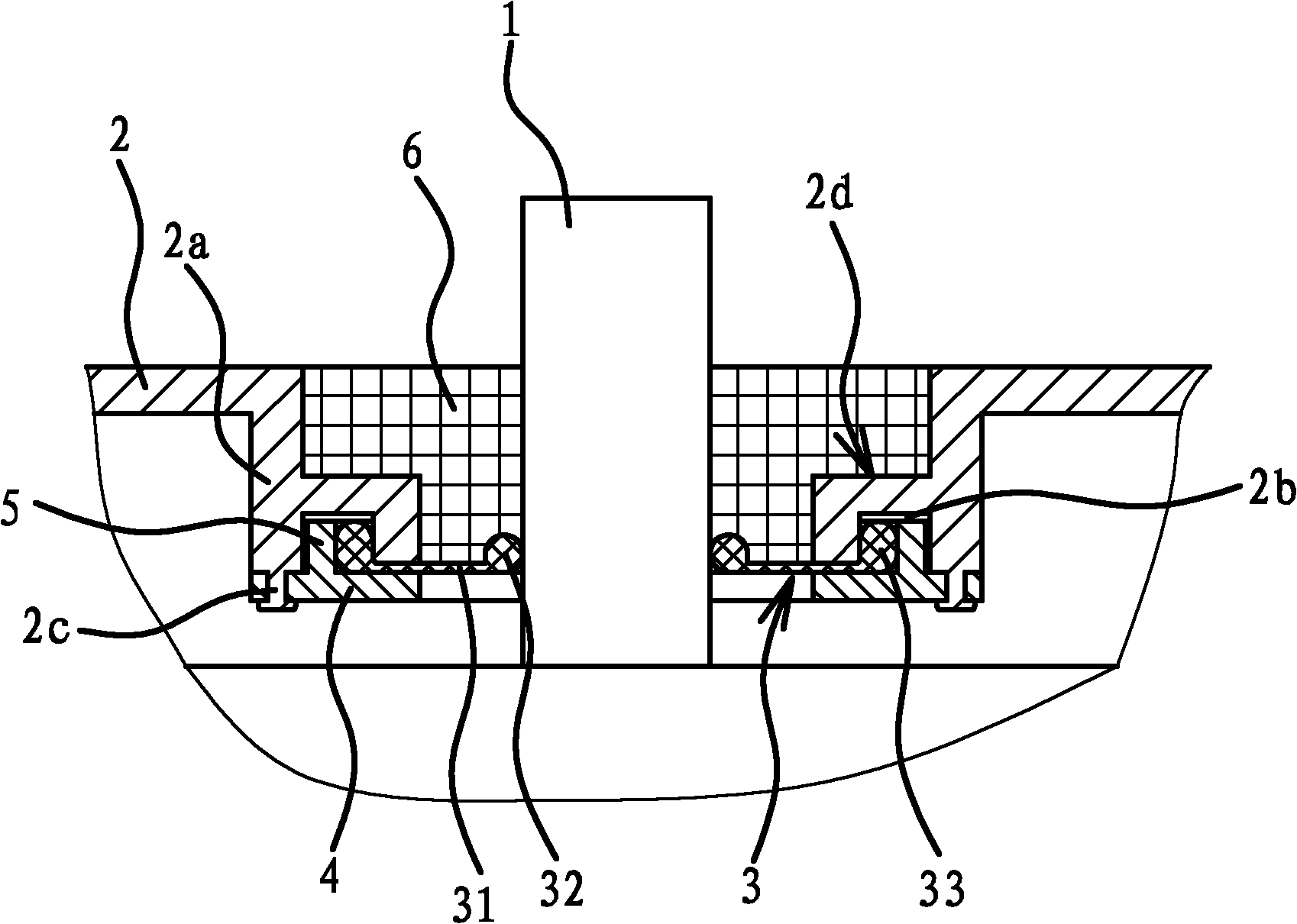

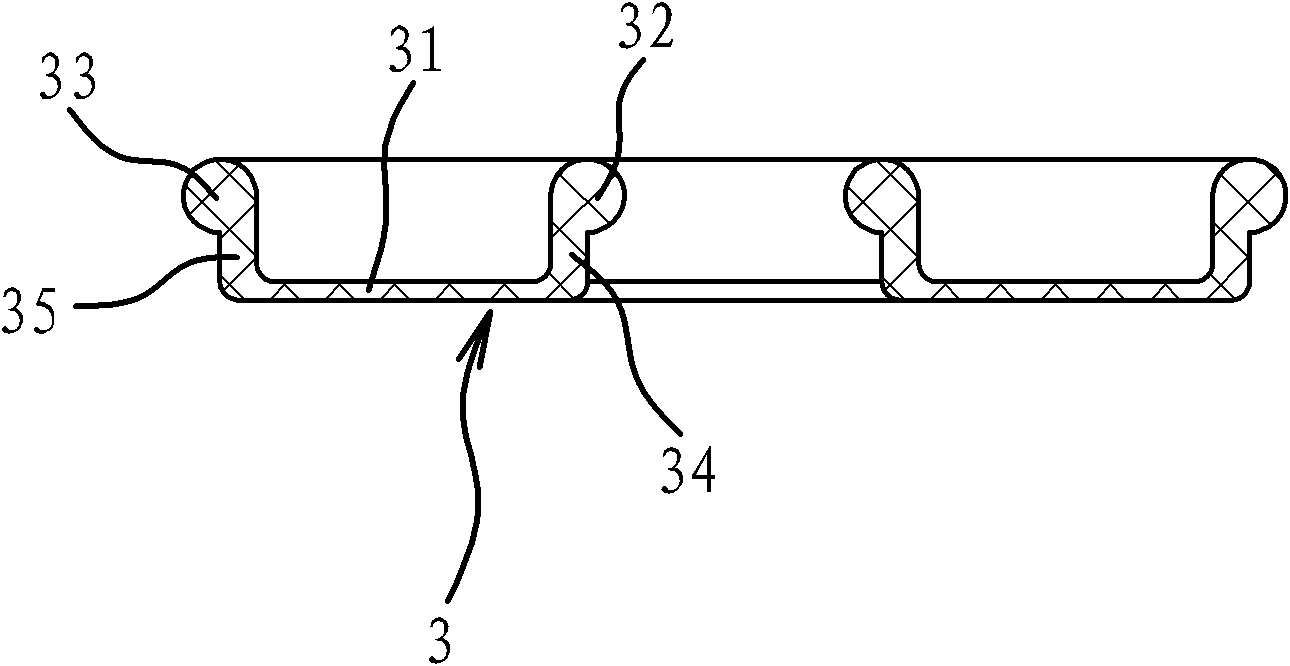

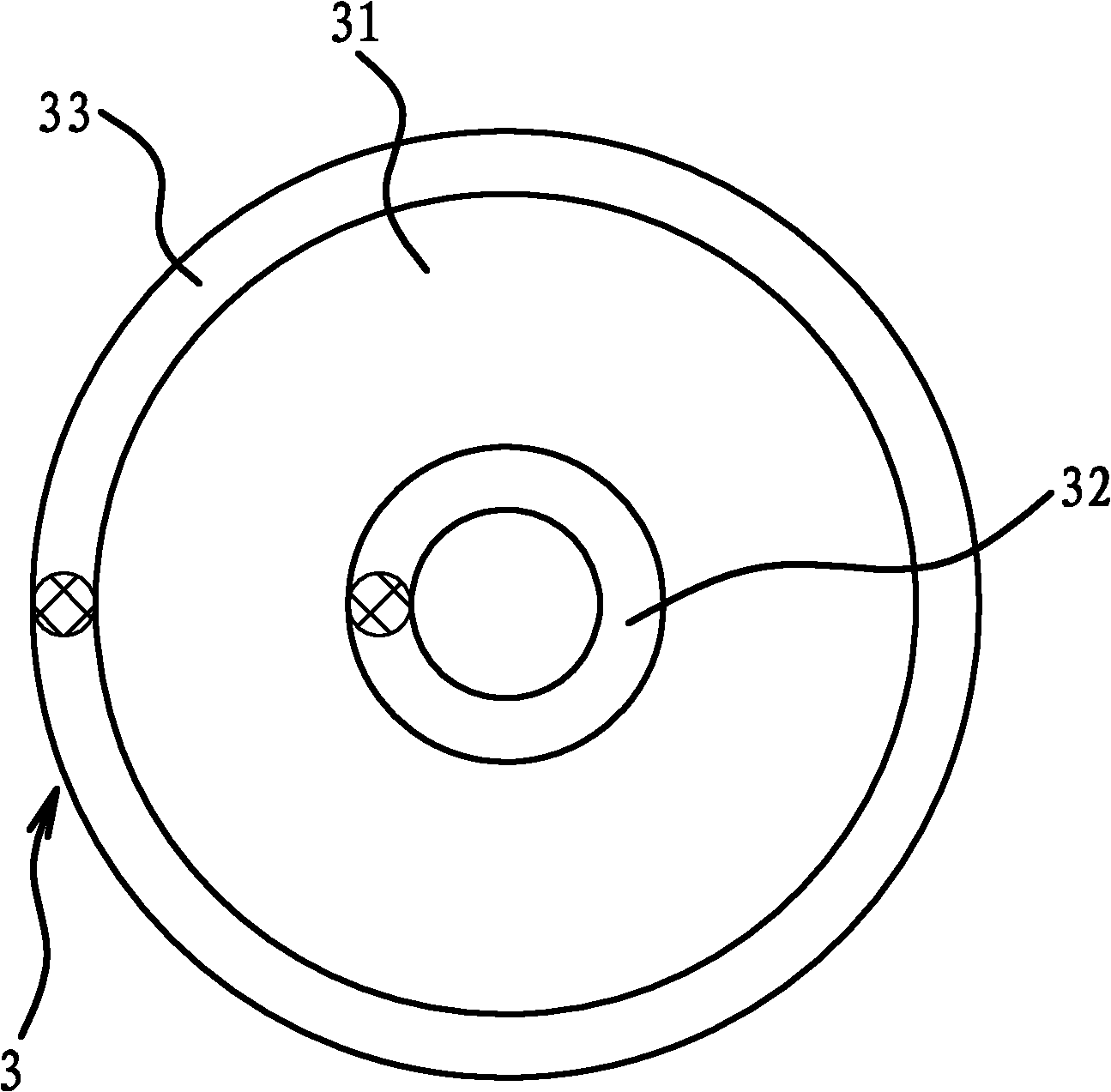

[0028] Such as figure 1 As shown, the battery includes a middle cover 2, a pole 1 and a sealing structure. The middle cover 2 has through holes corresponding to the pole 1 one to one, and the sealing structure also corresponds to the pole 1 one to one. The sealing structure of the pole 1 and the middle cover 2 includes a filling fixing member 6, a sealing member 3 and a fixing portion 2 a located at the edge of the through hole of the middle cover 2.

[0029] Specifically, such as figure 1 As shown, the ratio of the minimum value of the annular gap between the inner surface of the fixing portion 2a and the outer surface of the pole 1 to the diameter of the pole 1 is 1:2-20. The minimum value of the annular relief gap is directly related to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com