Proportional test device for rotating bending fatigue of train wheel axle

A bending fatigue and test device technology, applied in the field of rail transit, can solve problems such as the inability to simulate the actual working conditions of train wheels and axles, and achieve the effects of improving fatigue resistance, accurate test results, and good wheel and axle protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

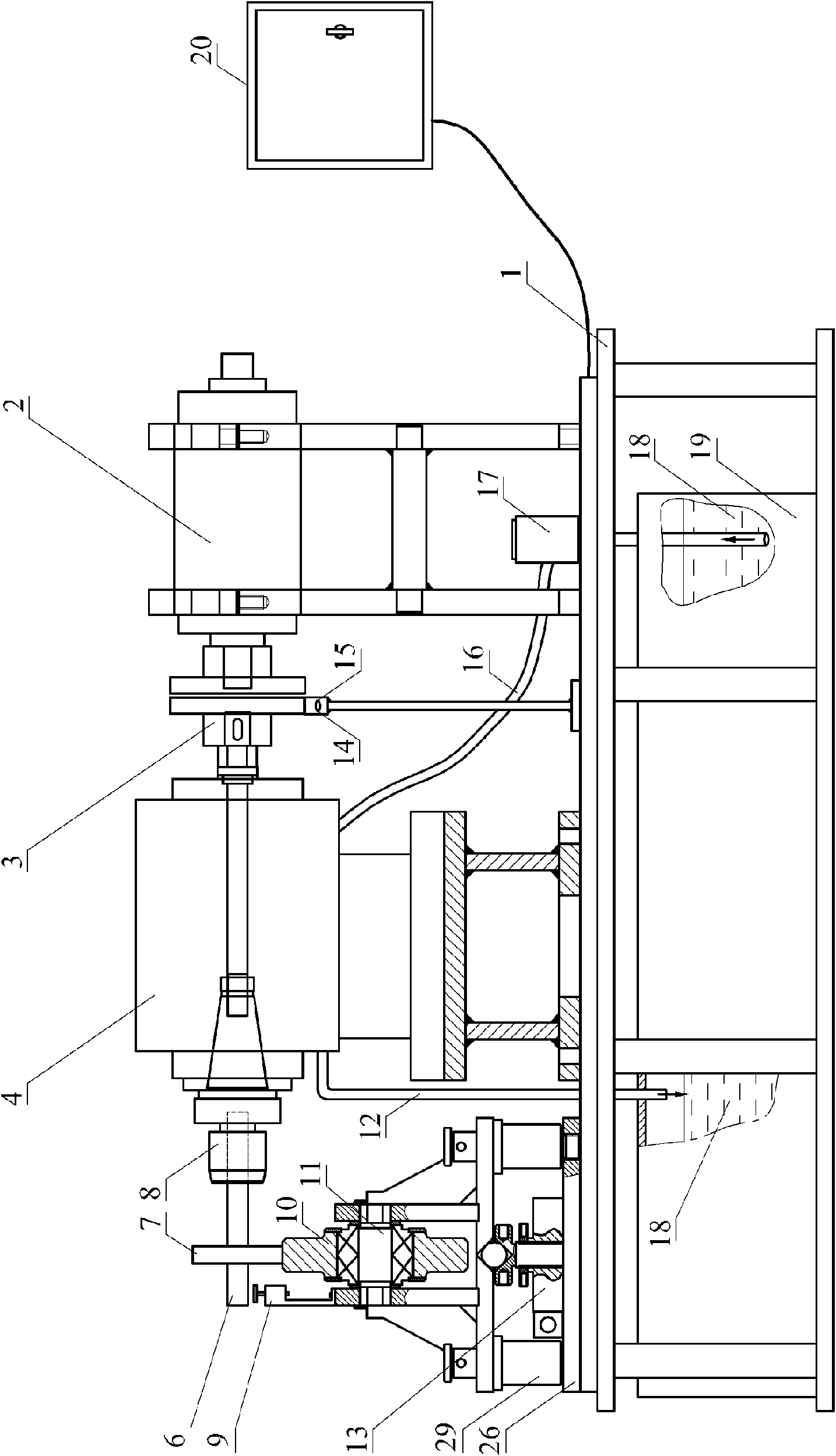

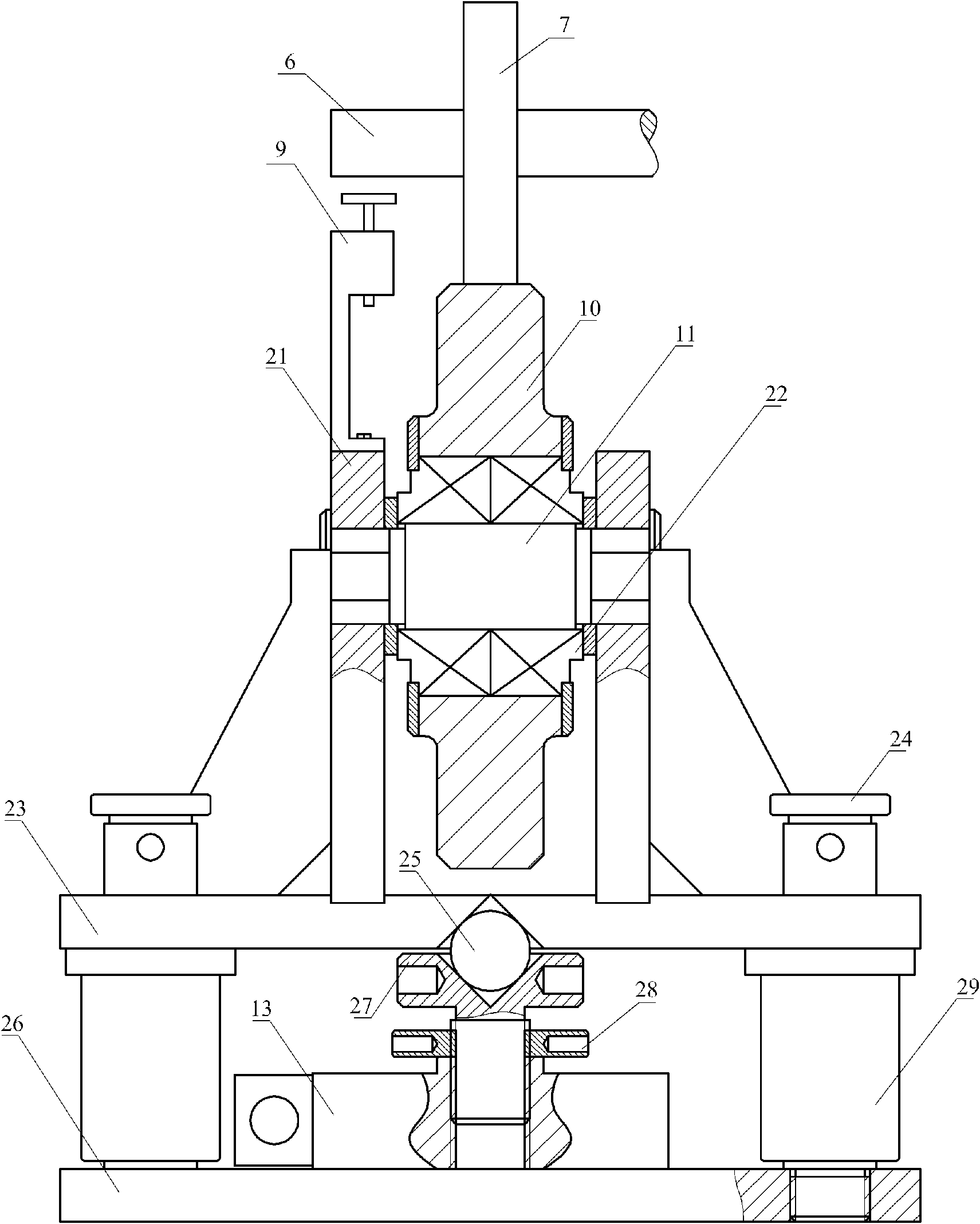

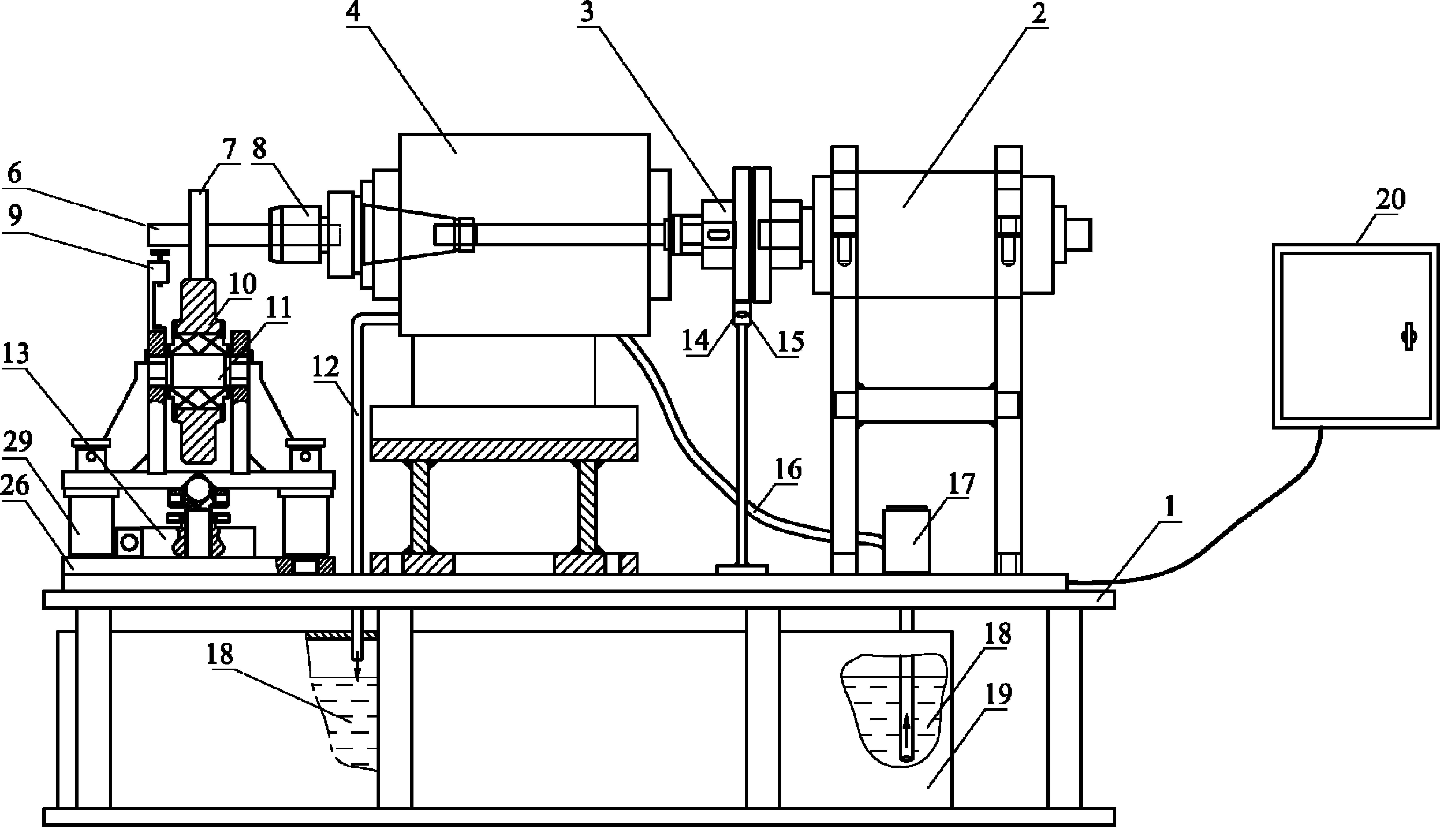

[0028] figure 1 , figure 2 Shown, a kind of specific embodiment of the present invention is, a kind of proportional test device of train wheel axle rotational bending fatigue, and its composition is:

[0029] The machine base 1 and the machine base 1 are equipped with an electric spindle 2 controlled by a data acquisition and control system 20. The electric spindle 2 is connected to the input end of the axle box 4 filled with cooling oil 18 through a coupling 3, and the axle box 4 The output end is connected to the collet 8; the collet 8 clamps the shaft 6 of the axle sample;

[0030] A speed sensor 14 and a speed sensor 15 are installed next to the shaft coupling 3;

[0031] The wheel 7 of the wheel shaft sample is in contact with the driven wheel 10 below, and the shaft 11 of the driven wheel 10 is installed on the driven wheel bracket 21 through the double-row bearing 22, and a guide sleeve 29 is fixed under the four corners of the bottom plate 23 of the driven wheel bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com