Combined ultrathin flexible uniformly distributed pressure loading device for geomechanical model tests

A model test and geomechanics technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem that the uniform distribution of load on the model surface cannot be achieved, the structure of the piston uniformly distributed pressure loader is complex, and it cannot meet the requirements of large-scale model tests. and other problems, to achieve the effect of easy and precise load control, flexible assembly and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings and embodiments.

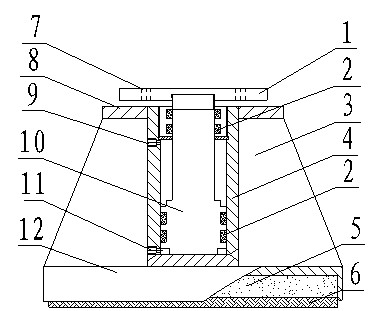

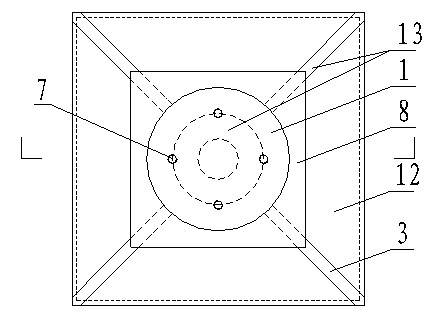

[0034] Such as figure 1 , figure 2 As shown, a composite ultra-thin flexible uniform pressure loading device for geomechanical model tests includes a hydraulic cylinder thruster 13, a two-way loading cylinder is provided in the center of the hydraulic cylinder thruster 13, and a connecting flange is provided on the top of the two-way loading cylinder piston 1. The bottom of the hydraulic oil cylinder thruster 13 is provided with a composite flexible force transmission cushion. The composite flexible force transmission cushion is fixed on the lower plate 12 by super glue.

[0035] The hydraulic cylinder thruster 13 includes an upper plate 8 and a lower plate 12. The lower plate 12 is a groove type. The center of the upper and lower plates is equipped with a two-way loading cylinder. The upper and lower plates are connected by a number of evenly distributed stiffeners 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com