Piston generator and power generation method

A generator and generator rotor technology, applied in reciprocating piston engines, variable capacity engines, machines/engines, etc., can solve problems such as low power generation efficiency and thermal energy loss, avoid thermal energy loss, improve efficiency, expand The effect of the form of energy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: Basic structure of reciprocating piston generator without crosshead

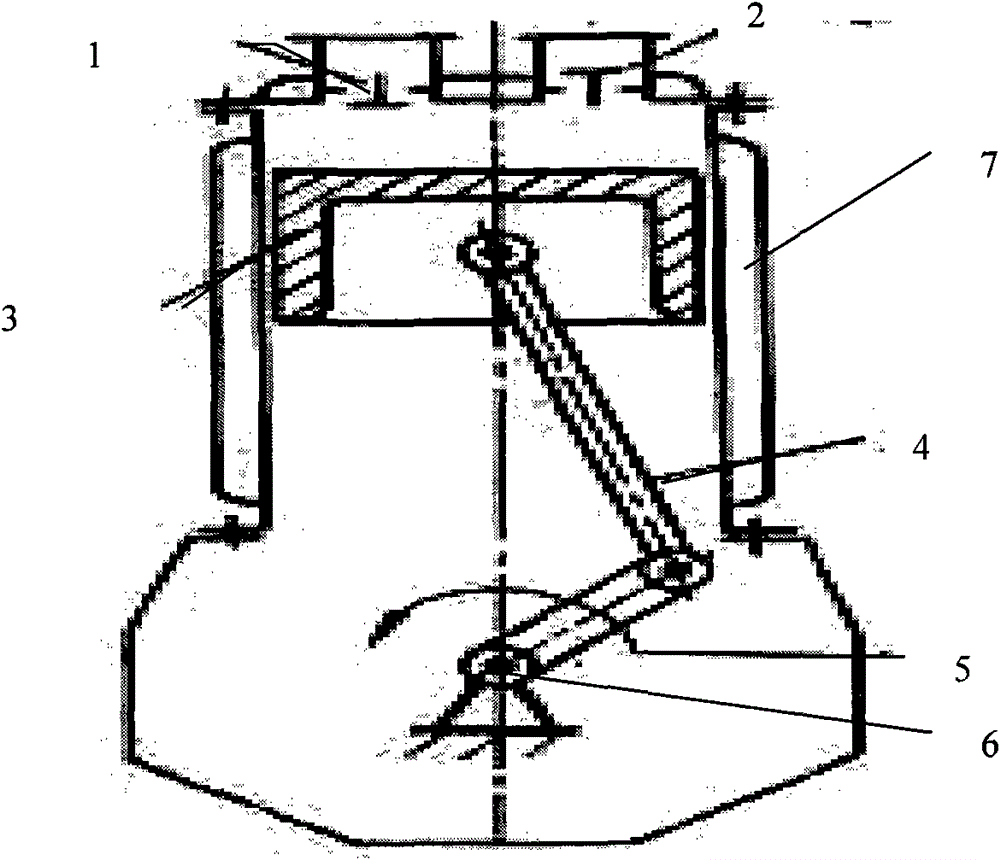

[0046] Such as figure 1 As shown, the piston 3 is arranged in the cylinder body 7, the inlet 1 and the outlet 2 of the fluid are arranged on the top of the piston, the piston 3 is connected with the rotor 6 of the generator through the connecting rod 4 and the crank 5, and the fluid enters from the fluid inlet and then the Expansion works, pushes the piston 3 to move, and the connecting rod and crank convert the reciprocating motion of the piston into rotation, realize the drive of the generator rotor, and realize the conversion of the kinetic energy of the fluid into electric energy.

Embodiment 2

[0047] Embodiment 2: Generator with reciprocating piston compressor structure driven by turntable

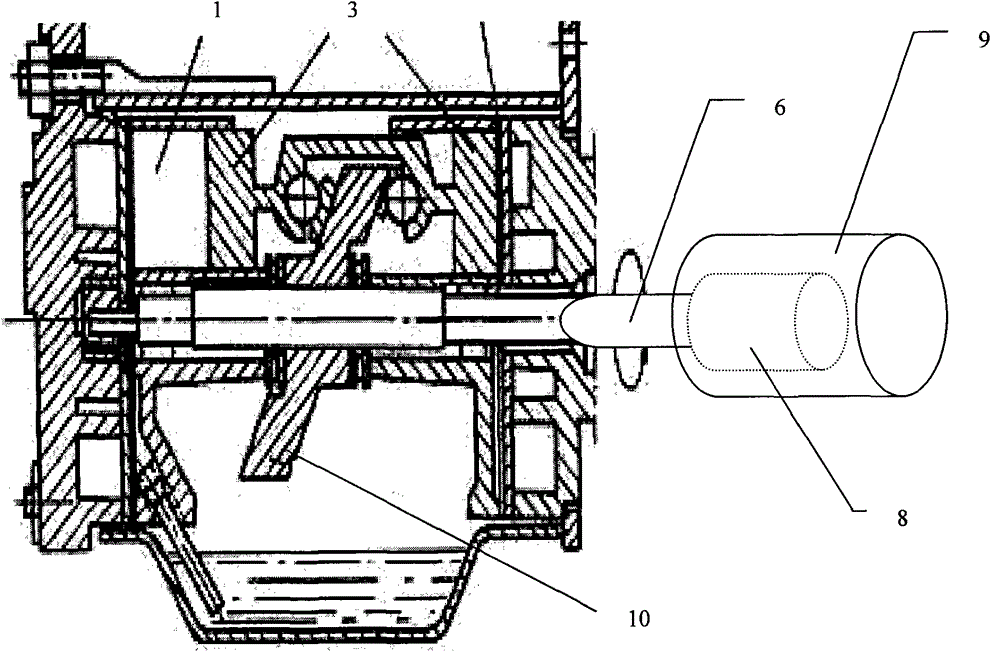

[0048] Such as figure 1 As shown, there are two pistons 3 and two cylinders 7 in this example, and the two pistons are connected by a turntable 10, and the two pistons drive the generator rotor 8 through the drive mechanism, and the generator rotor 8 is connected to the The stators around it create motion against each other, which converts fluid motion energy into electrical energy.

[0049] Liquid, gas, etc. or a mixture of liquid and gas can be used to generate electricity, so that the waste heat and pressure can be fully utilized, or supplemented by solar energy, shallow surface thermal energy, and traditional energy.

Embodiment 3

[0050] Embodiment 3: Counter-moving reciprocating piston generator

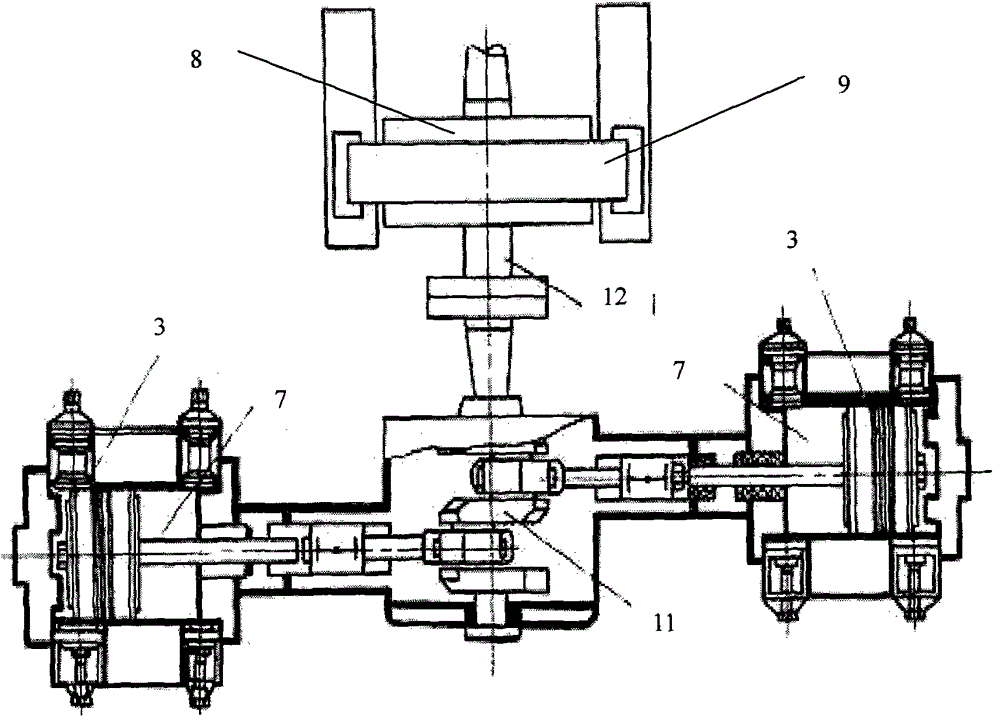

[0051] Such as image 3 As shown, this example is a horizontal structure, and the cylinders 7 are horizontally arranged on both sides of the crankshaft 11. The structure that moves toward or away from the two rows at the same time is called a counter-moving type, and the arrangement of the two cylinders 7 and the two pistons 3 facing the back On both sides of the generator, the cylinders are jointly connected with a drive shaft 11, the generator rotor 8 is set on the drive shaft, and the stator 9 of the generator is set around it, and the fluid flows from the ports and ports on the two cylinders. The outlet expands inside the cylinder and works, driving the piston in the cylinder to reciprocate. The driving mechanism converts the reciprocating motion into rotation and drives the generator rotor installed on the rotating shaft, thereby converting the kinetic energy of the fluid into electrical energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com