Cheese and method for producing the same

A manufacturing method and cheese technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problem of absence of calcium, etc., and achieve the effect of good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

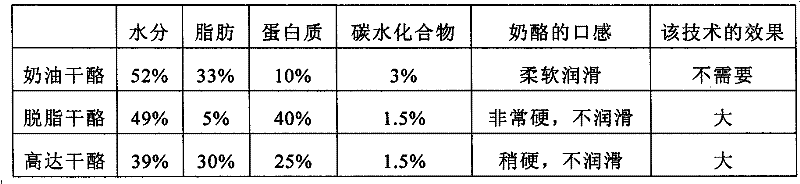

Method used

Image

Examples

Embodiment 1

[0074] 5 kg of frozen Gouda cheese and 5 kg of cheddar cheese were pulverized with a freeze cutter. The composition of the cheese which combined both was 38 weight% of water|moisture content, 31 weight% of fat content, and 26 weight% of protein contents. 50 g of protein powder and 50 g of dextrin were added therein and fully mixed. After returning to room temperature, a simple tablet forming machine was used to form a cuboid of 2 cm × 4 cm × 1.5 cm and cooled. Trial-produce 50 rectangular parallelepiped cheeses. The rectangular parallelepiped cheese maintains its shape firmly even when held by hand, is easily disintegrated in the mouth when eaten, has good solubility in the mouth, is not sticky, and has a good mouthfeel.

Embodiment 2

[0076] After pulverizing 8 kg of gouda cheese and 2 kg of cheddar cheese with a meat grinder (sieve hole 4.8 mm phi), fully mix, and use a simple tablet forming machine to form a cuboid of 2 cm × 4 cm × 1.5 cm and cool. Trial-produce 50 rectangular parallelepiped cheeses. The composition of the combined cheese was 41 weight% of water|moisture content, 28 weight% of fat content, and 26 weight% of protein contents. The rectangular parallelepiped cheese maintains its shape firmly even when held by hand, is easily disintegrated in the mouth when eaten, has good solubility in the mouth, is not sticky, and has a good mouthfeel.

Embodiment 3

[0078] Cheddar cheese 9kg is pulverized with a meat grinder (sieve plate hole 3mmφ), fully mixed with powdered cheese 1kg, and formed into a disc shape with a diameter of 3cm and a thickness of 7mm using a simple tablet forming machine. Trial production of 50 disc-shaped cheeses. The composition of the cheese which combined both was 33 weight% of water|moisture content, 35 weight% of fat content, and 26 weight% of protein contents. The disc-shaped cheese maintains its shape firmly even when held by hand, is easily disintegrated in the mouth when eaten, has good solubility in the mouth, is not sticky, and has a good mouthfeel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com