Semiconductor device and method for manufacturing the same

A technology for semiconductors and devices, applied in the field of semiconductor devices and their manufacturing, can solve problems such as increased cost, increased number of processes, and inability to form component areas, and achieves the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

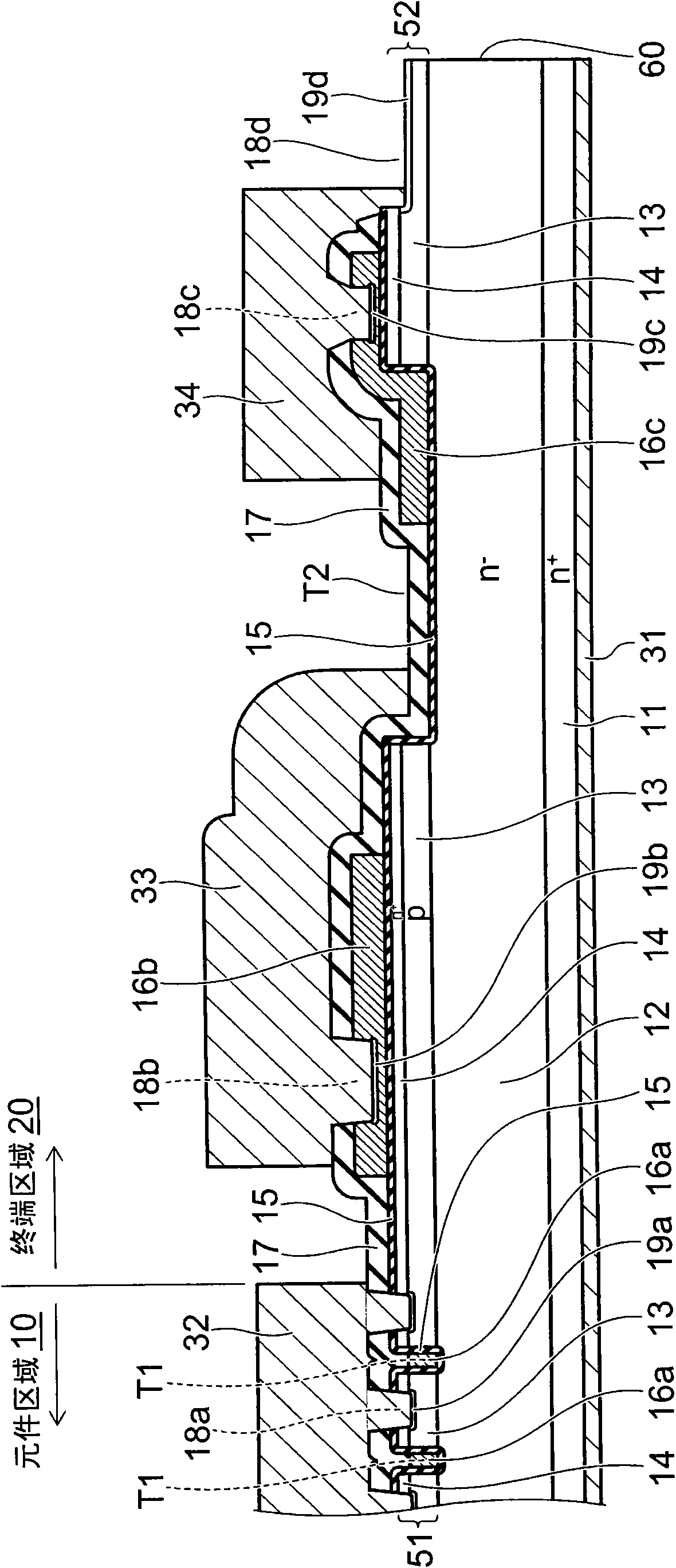

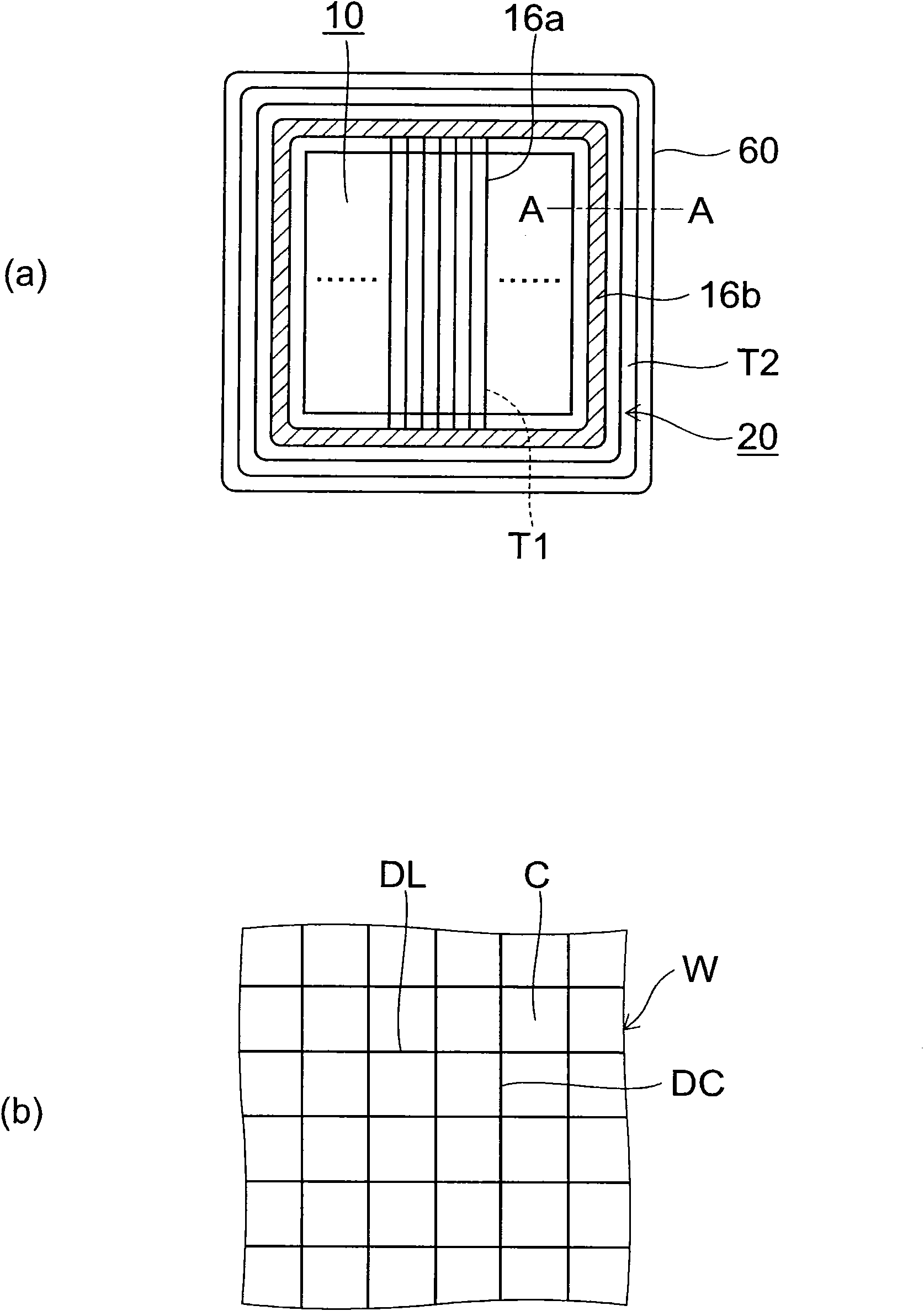

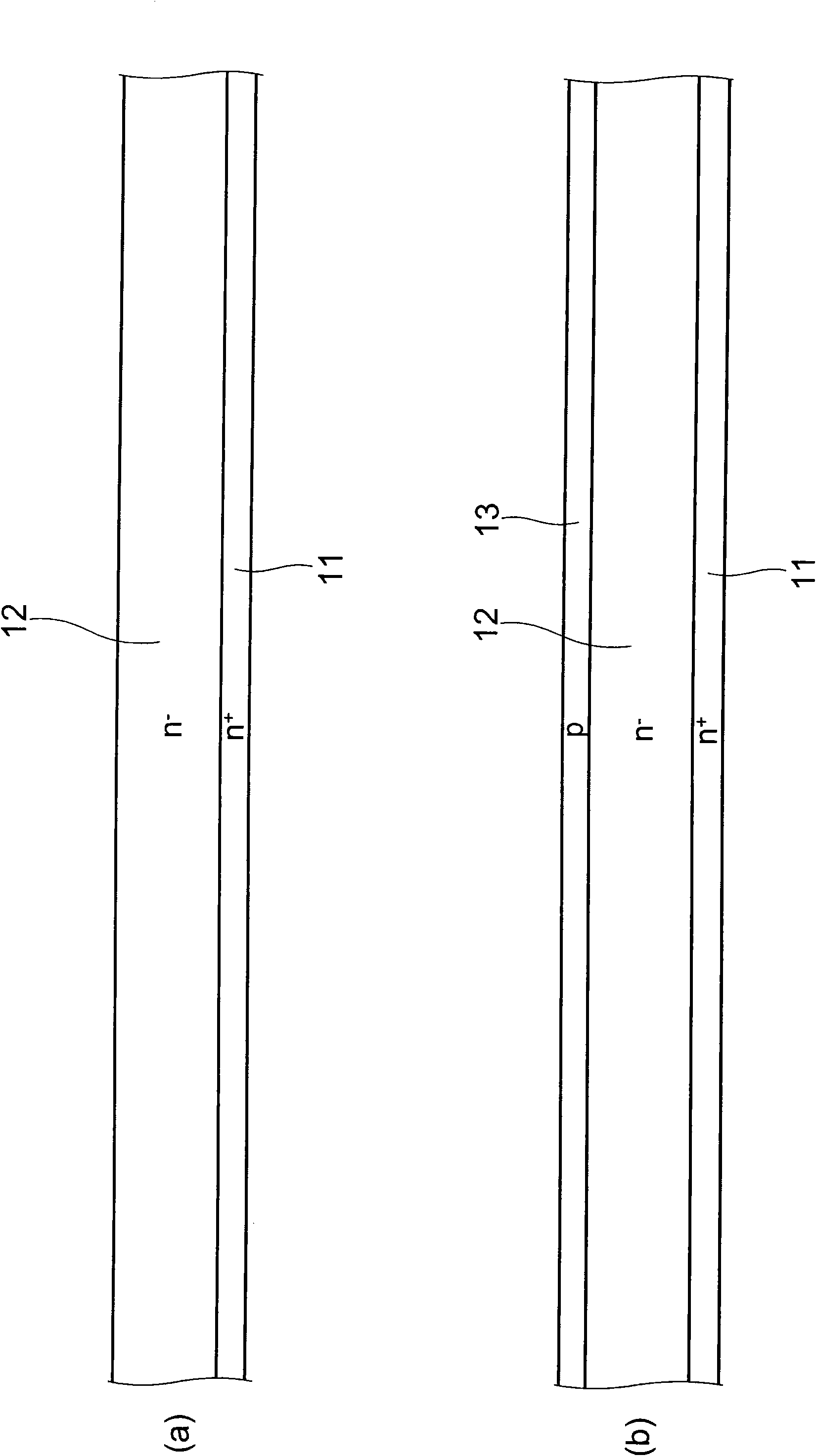

[0016] According to an embodiment, a semiconductor device includes a first semiconductor layer of the first conductivity type, a second semiconductor layer of the first conductivity type, a third semiconductor layer of the second conductivity type, a fourth semiconductor layer of the first conductivity type, a first trench A groove, a second trench, an insulating film, a gate electrode, a first main electrode, a second main electrode, a channel stopper layer, and a channel stopper electrode. The second semiconductor layer is provided on the first semiconductor layer, and has a lower first conductivity type impurity concentration than the first semiconductor layer. The third semiconductor layer is disposed on the second semiconductor layer. The fourth semiconductor layer is disposed on the third semiconductor layer, and the impurity concentration of the first conductivity type is higher than that of the second semiconductor layer. The first trench penetrates through the fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com