Device for enhancing uniformity of electron beam current

A technology of electron beam current and uniformity, which is applied in the field of space applications, can solve the problems of uniformity of electron beam current, deterioration, and poor performance of filaments that are prone to deformation, and achieve the effect of not easily deformed, uniform scattering, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to fully illustrate the characteristics of the present invention and the mode of carrying out the present invention, examples are given below.

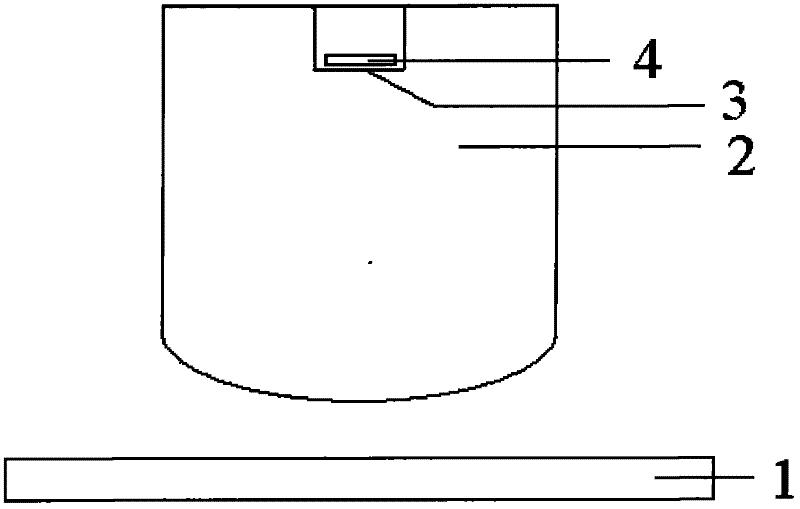

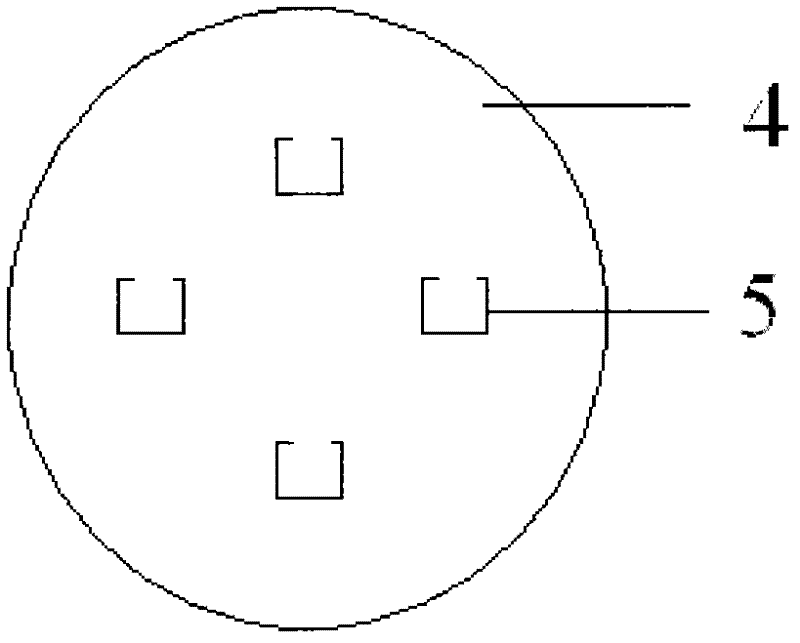

[0017] In the scattering type low-energy electron gun 2, the diameter of the circular disc-shaped spiral filament 3 is 5mm, and the diameter of the circular asbestos seat 4 is 4mm. The filament 3 is fixed on the asbestos seat 4, and the electron scattering net 1 is placed 50 mm outside the emission hole of the electron gun 2. The diameter of the hole in the electron scattering net 1 is 0.1 mm, and the electron scattering net 1 is a metal copper grid. net, see figure 1 and figure 2 .

[0018] Select a circular area with a diameter of 200mm at the place where the electron beam of the electron gun 2 is ejected, and select 5 points uniformly distributed in the circular area as test points for testing, and use the center point as the basis point 1 for electron beam testing. For comparison of flow uniformity, the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com