Overall test and construction method of differential protection system of large-scale transformer

A differential protection and whole group test technology, applied in the direction of instruments, measuring electrical variables, measuring devices, etc., can solve the problems of the test method that does not reflect the large current of the primary circuit, the limited capacity of the test equipment, etc., and achieve the goal of debugging technology Simplified equipment, guaranteed complete test significance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

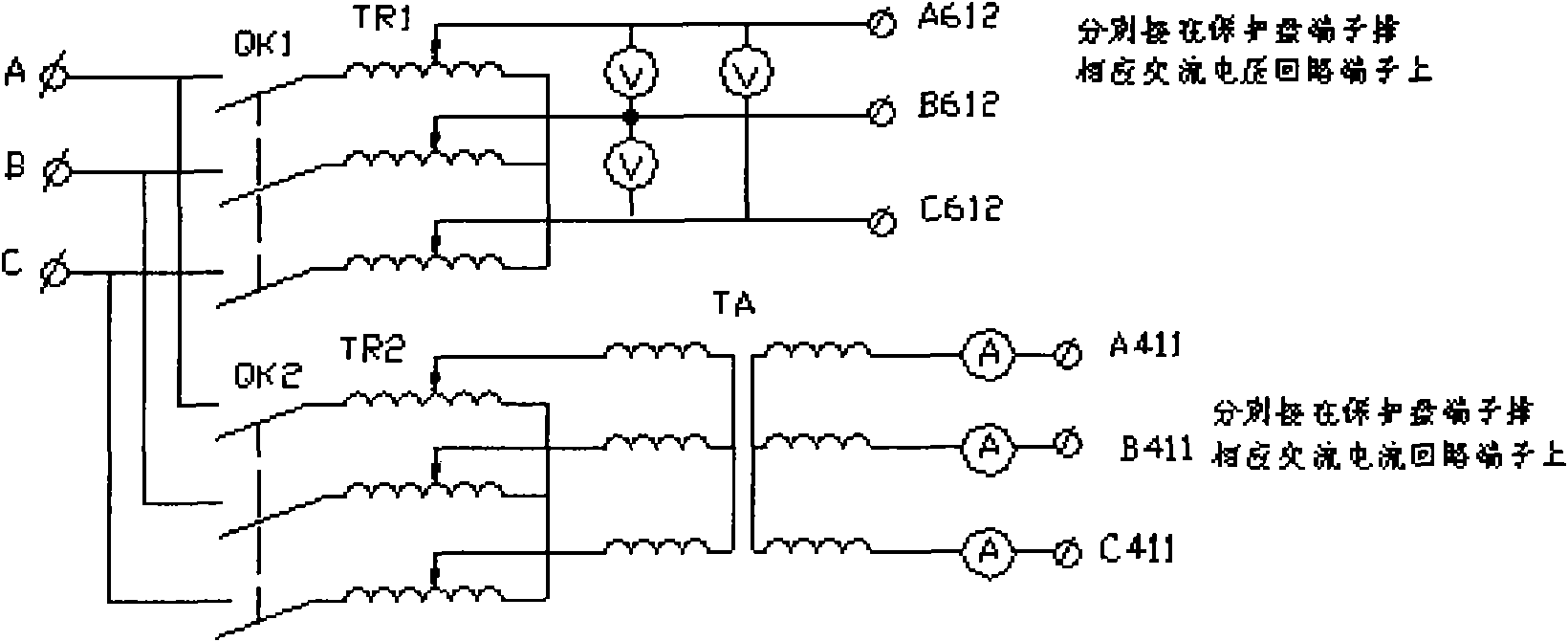

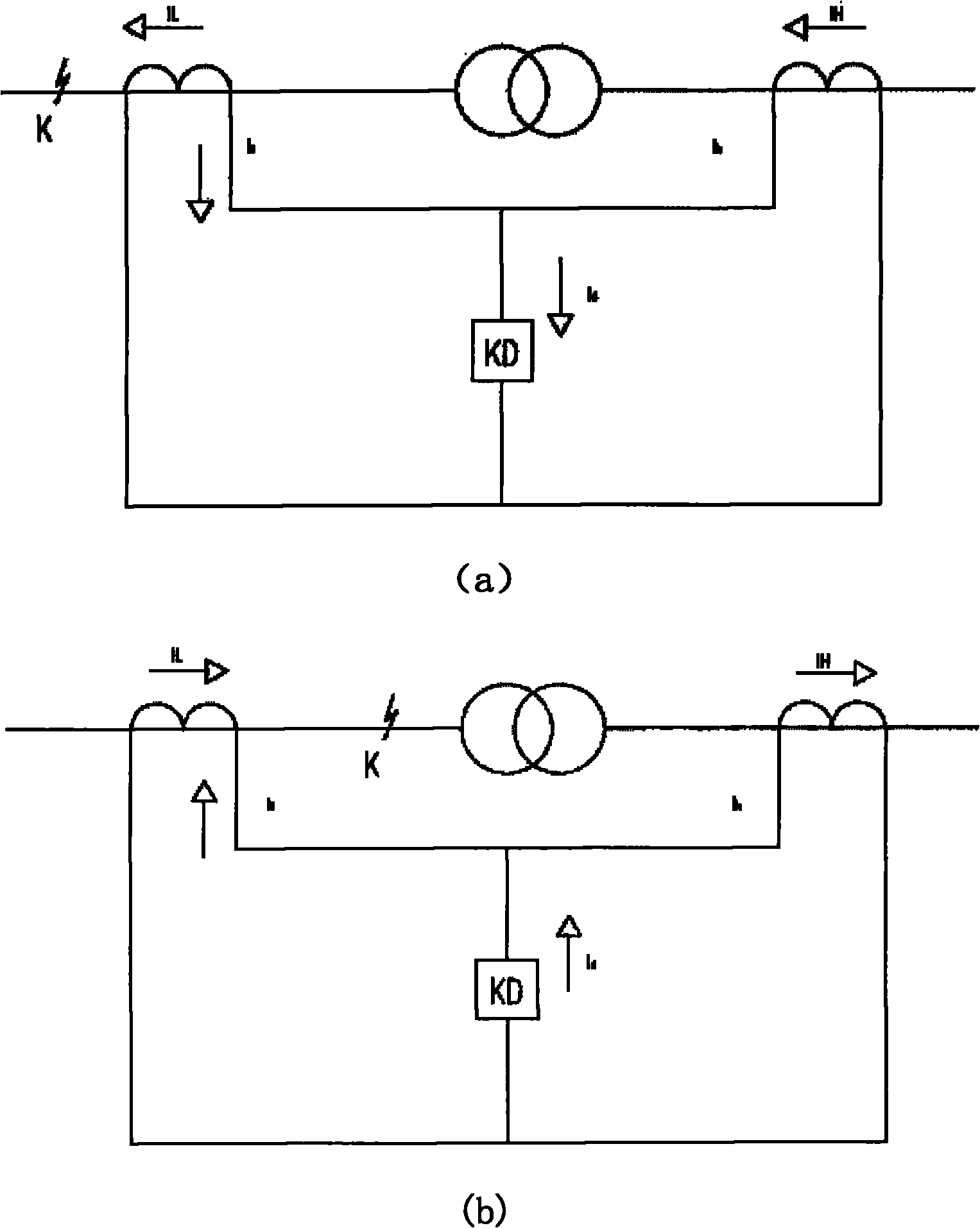

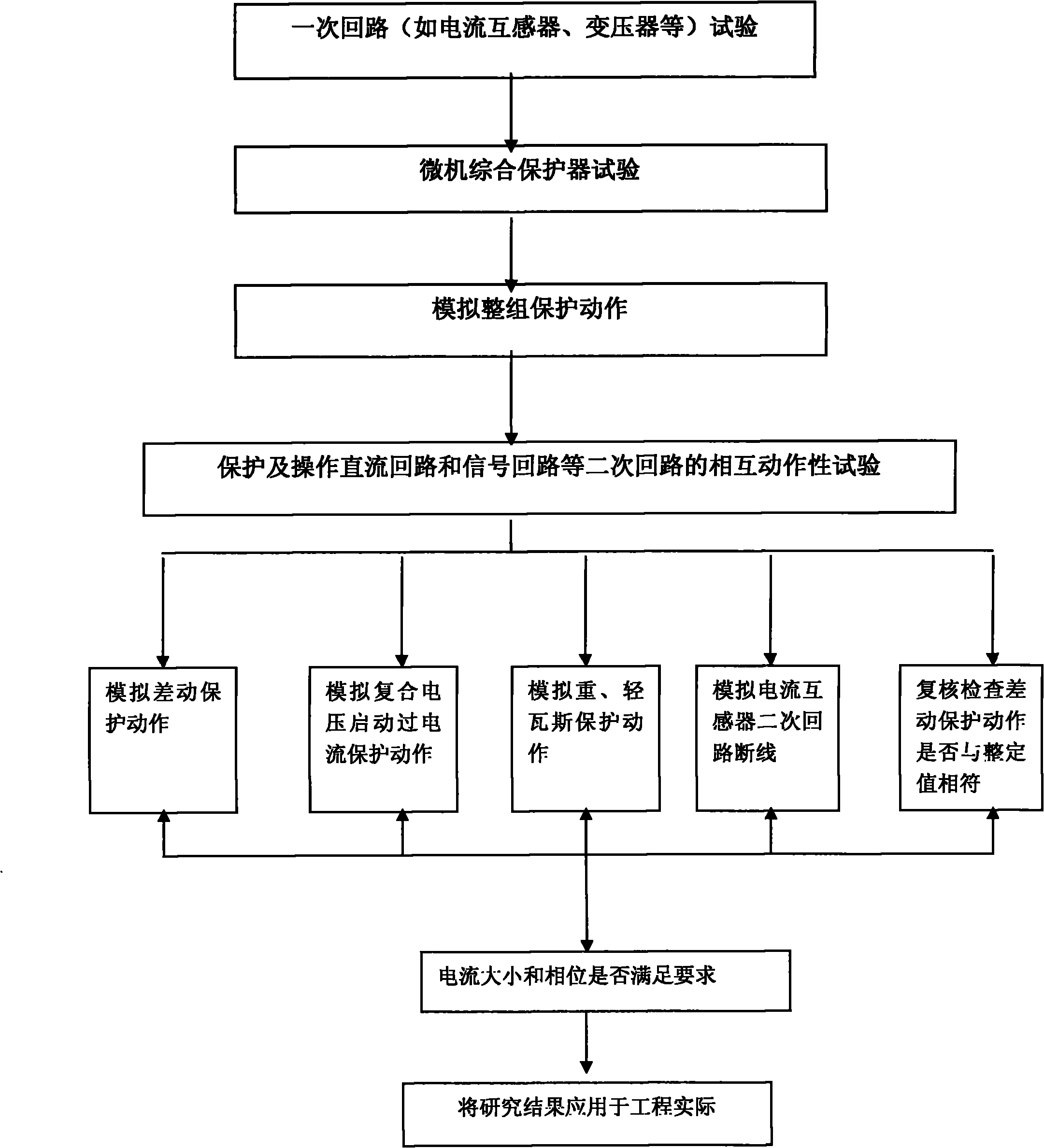

[0025] The present invention adopts a whole set of test methods, mainly short-circuiting the low-voltage side of the transformer and adding a low-voltage power supply to the high-voltage side, such as a 380V construction power supply, or short-circuiting the high-voltage side of the transformer and adding a power supply to the low-voltage side to obtain a short-circuit large current. So this whole set of tests is also called short-circuit test.

[0026] 1. The basic principle of transformer differential protection:

[0027] The differential protection system implements transformer power supply disconnection protection after comparing the current magnitude and phase of the high and low voltage sides of the transformer. When the transformer is in normal operation, the currents of the secondary circuits of the high and low voltage side current transformers are equal in size and opposite in direction, the current flowing through the differential circuit is zero, and the differenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com