Rotary part surface quality detection system

A technology of surface quality and detection system, which is applied in the direction of optical testing for flaws/defects, etc., can solve the problems of unstable detection results, high labor intensity of workers, and low production efficiency, and achieve low labor intensity of workers, simple structure, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawings and implementation.

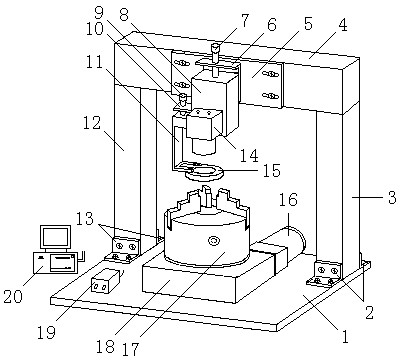

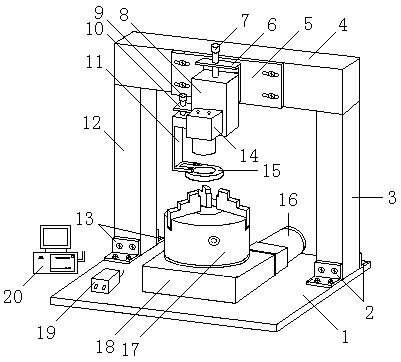

[0013] Such as figure 1 As shown, the surface quality inspection system for rotary parts of the present invention includes a base plate 1, a left connecting block 13, a left column 12, a right connecting block 2, a right column 3, a beam 4, a positioning plate 5, a large support plate 6, and a camera base 8. Camera 14, small support plate 10, first adjustment lever 7, second adjustment lever 9, connecting plate 11, light source 15, motor 16, transmission box 18, three-jaw chuck 17, light source regulator 19, monitoring operating system 20.

[0014] The left column 12 is installed on the left front part of the base plate 1 through two left connecting blocks 13, the right column 3 is installed on the right front part of the base plate 1 through two right connecting blocks 2, and the beam 4 is fixed on the left column 12 and the right column 3 to form a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com