Air-tightness detection device for automobile axle assembly

A technology for air tightness testing and automobiles, which is applied in measuring devices, vehicle testing, and liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems of undetectable assembly leakage, unsatisfactory effect, poor sealing, etc. problems, to achieve the effect of eliminating hidden dangers in product production, reducing post-engineering defective products, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

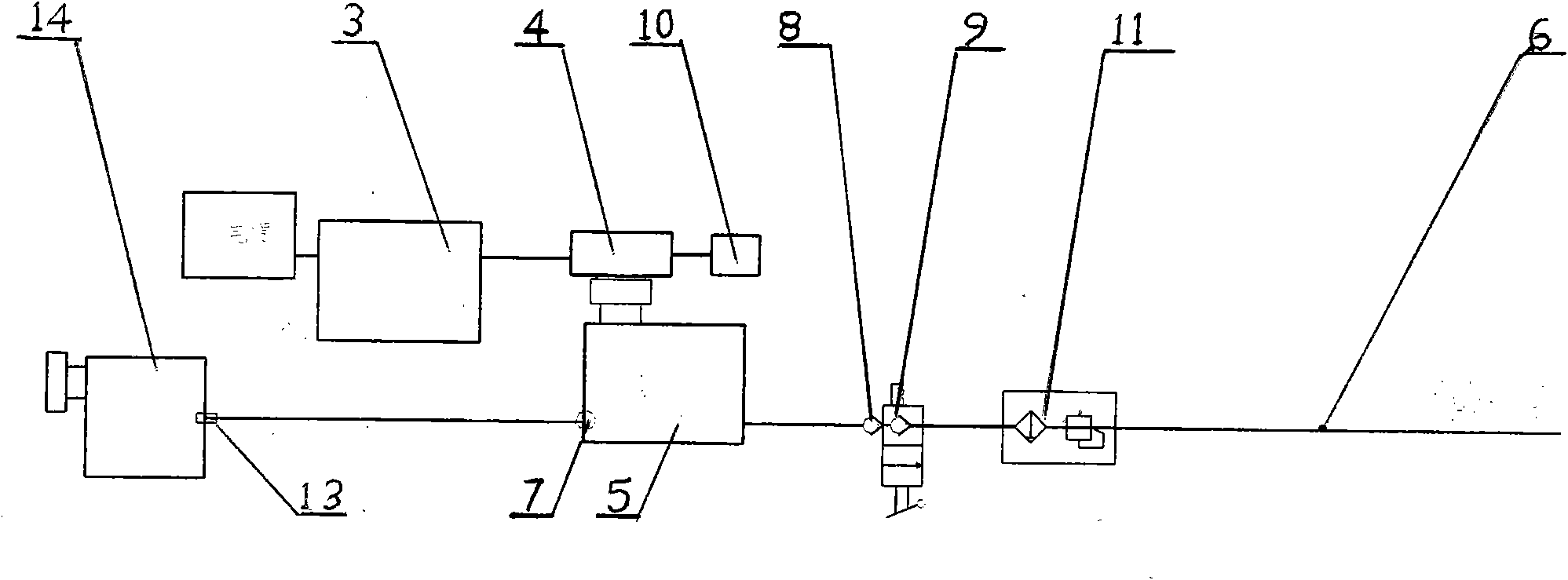

[0016] Such as figure 1 , figure 2 As shown, the pressure-resistant box 1 of the present invention is equipped with an electric control part and a sealing detection part, and the sealing detection part includes an air storage tank 5, a one-way control valve 8, a manual control valve 9, a filter pressure reducing valve 11, a sealing air plug 13 and the trachea.

[0017] The gas source is connected to the air inlet 6 of the gas storage tank 5 in the pressure-resistant box 1 through a manual control valve 9 and a one-way control valve 8. The one-way control valve 8 can prevent the gas entering the gas storage tank 5 from flowing back and prevent detection Hidden danger, the manual control valve 9 is used to control the air pressure entering the gas storage tank 5; the gas outlet 7 of the gas storage tank 5 is communicated with the vent plug hole of the part 14 through the sealing air plug 13 through the air pipe through the filter pressure reducing valve 11, and the filter redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com