Coupling

A technology of couplings and threaded sliders, applied in the direction of couplings, elastic couplings, connecting components, etc., can solve the problems of reduced service life of couplings, high use costs, high processing costs, etc., and improve work efficiency , improve the service life and balance the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

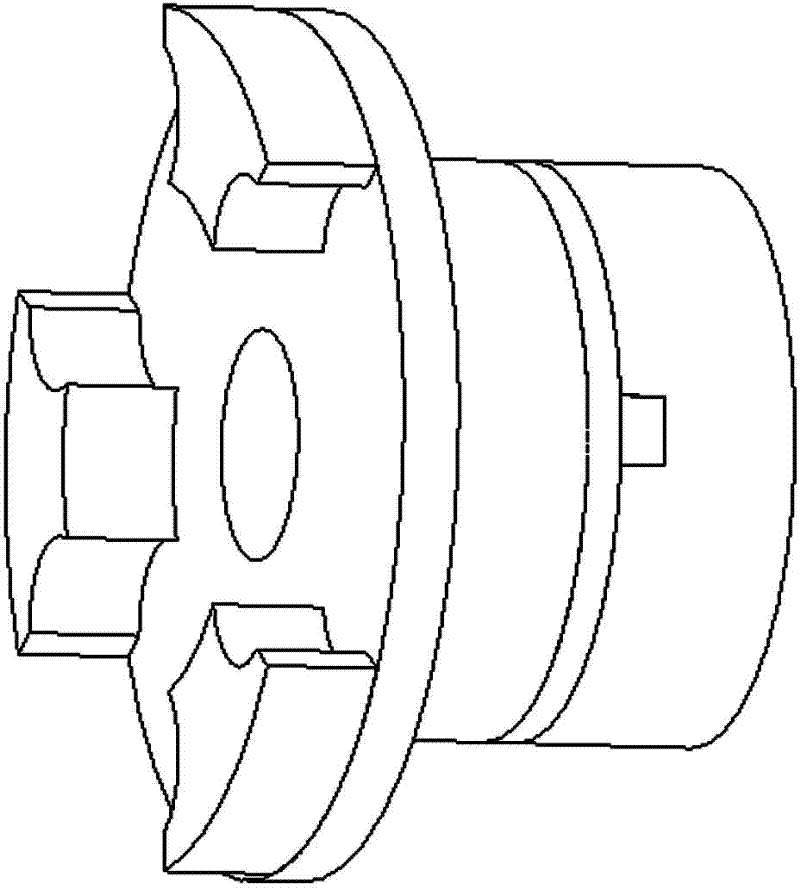

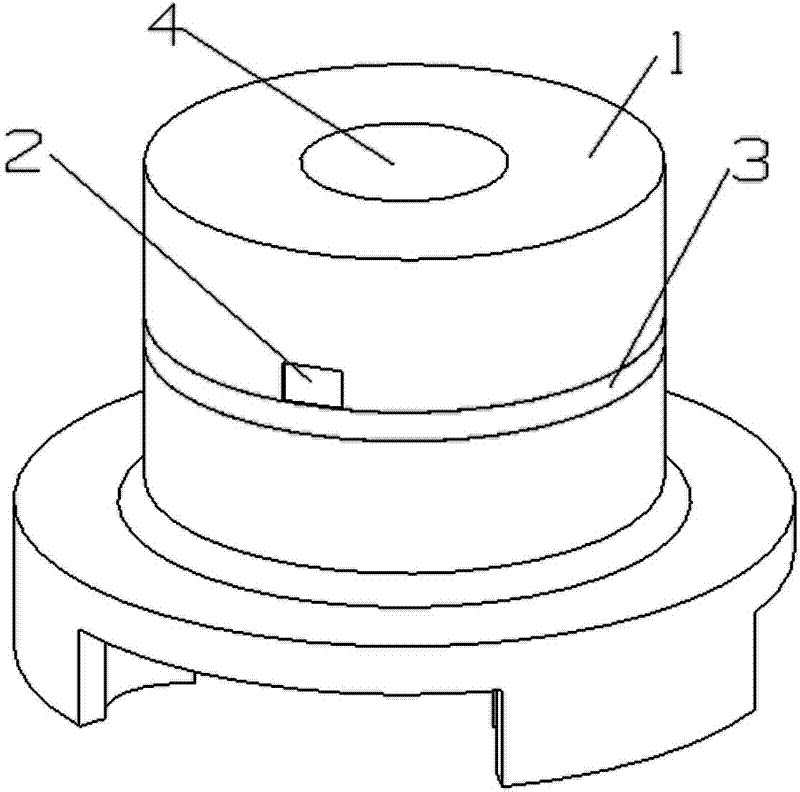

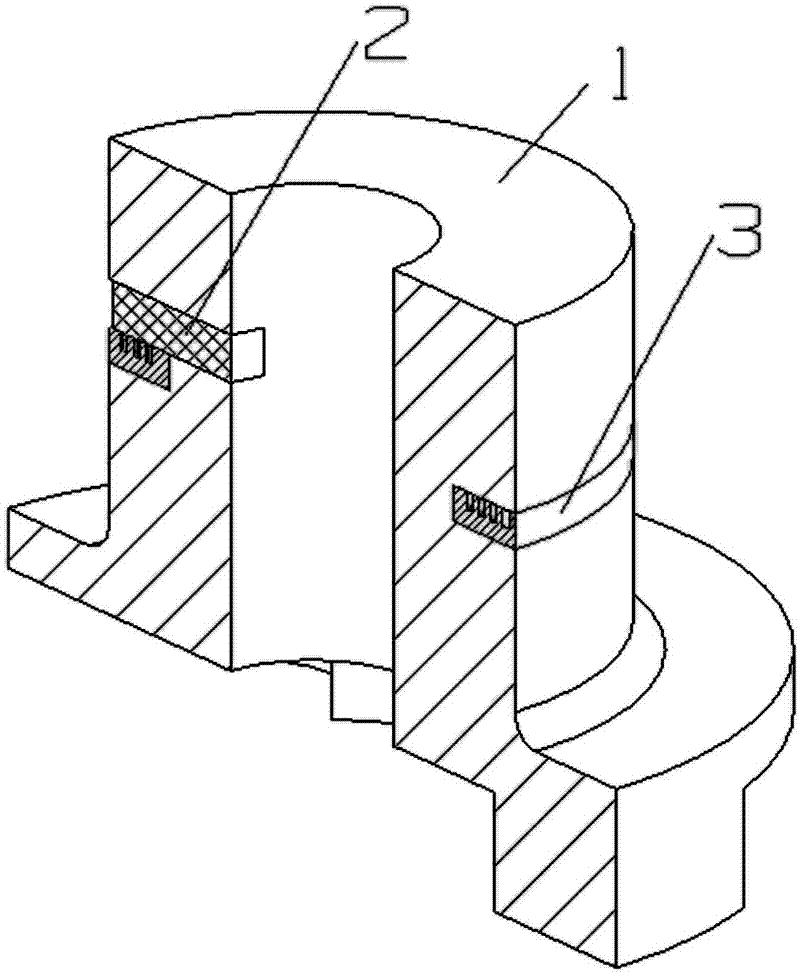

[0018] The elastic coupling includes two half-couplings with the same structure and an intermediate elastic member (not shown), the structure of the half-coupling is as follows figure 1 As shown, the two half-couplings are respectively connected to the two shafts, and the intermediate elastic member is installed between the two half-couplings. figure 2 The structure of the coupling half is shown from another angle, image 3 It is a cross-sectional view of the half coupling. The center of the half coupling 1 has a shaft hole 4, and the shaft hole 4 has an internal spline structure (not shown), which is used to cooperate with the external spline of the shaft, and also has an annular groove for To accommodate flat threaded discs. The flat threaded disc 3 is arranged coaxially with the half-coupling 1 and is located in the groove of the half-coupling. One plane of the flat threaded disc 3 has a rectangular threaded groove 6, such as Figure 5 As shown, the outer circumference o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com