Ventilation-humidification coupled solid-state fermentation tank and fermentation process thereof

A solid-state fermenter and gas-humidity technology, which is applied in the direction of solid-phase fermentation bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problems of high cost, reduced strength, tightness, etc. It is not easy to grasp and other problems, and achieves the effects of low production cost, convenient operation and simple structure

Inactive Publication Date: 2011-06-15

UNIV OF SCI & TECH BEIJING

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the existing solid-state fermentation devices, ventilation, humidification, and heat dissipation are usually handled separately, and there are problems in the principle and manufacture, complex operation control, and high cost.

[0004] The methods used to sterilize the incoming air mainly include radiation sterilization, thermal sterilization, and electrostatic sterilization. The medium used for filter sterilization, such as cotton, glass fiber, and activated carbon, is time-consuming and laborious to fill, and the tightness is not easy to control; paper The strength of similar filter media such as ultrafine glass fiber paper will decrease after being damp, which will affect the air filtration effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

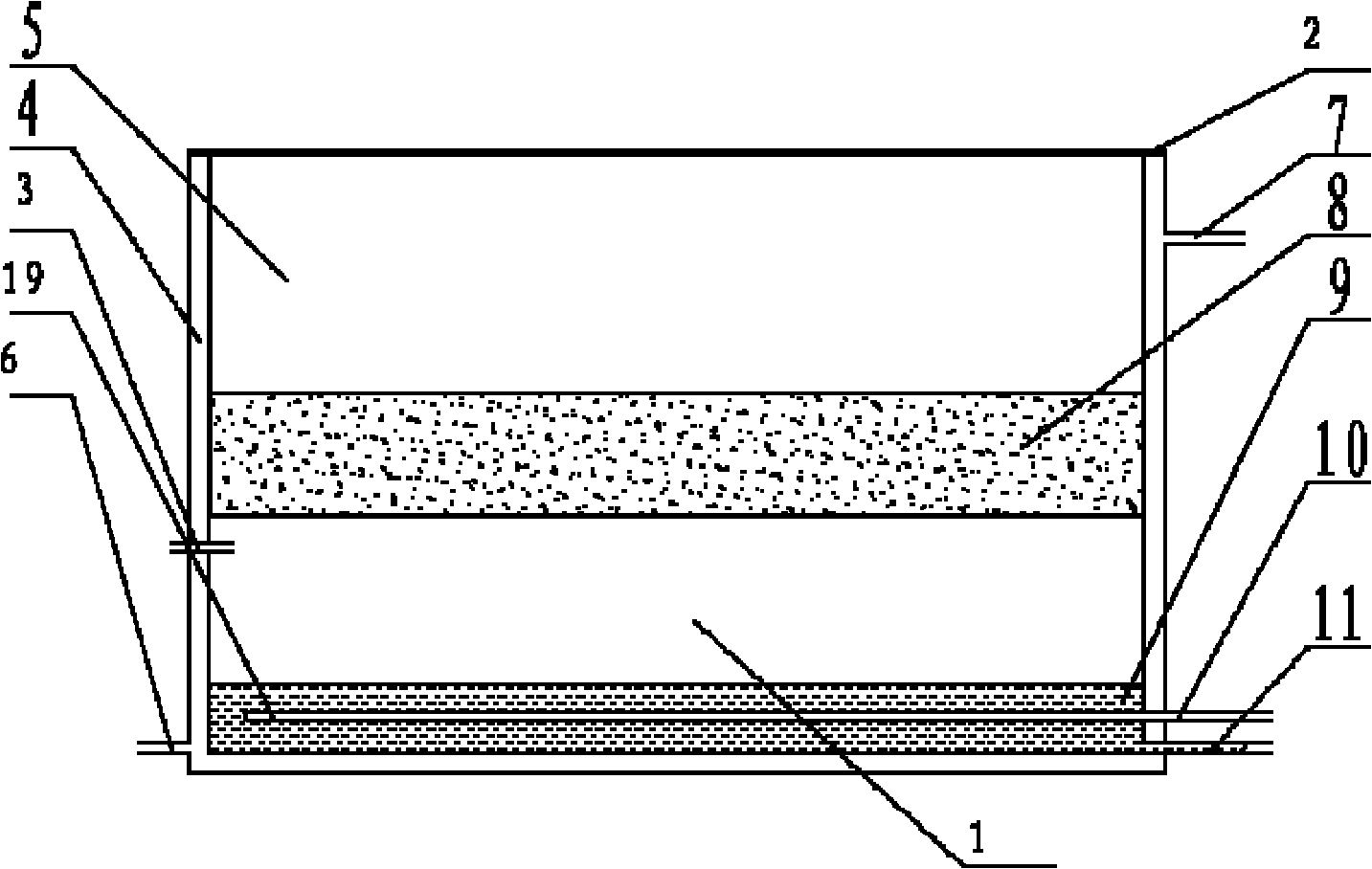

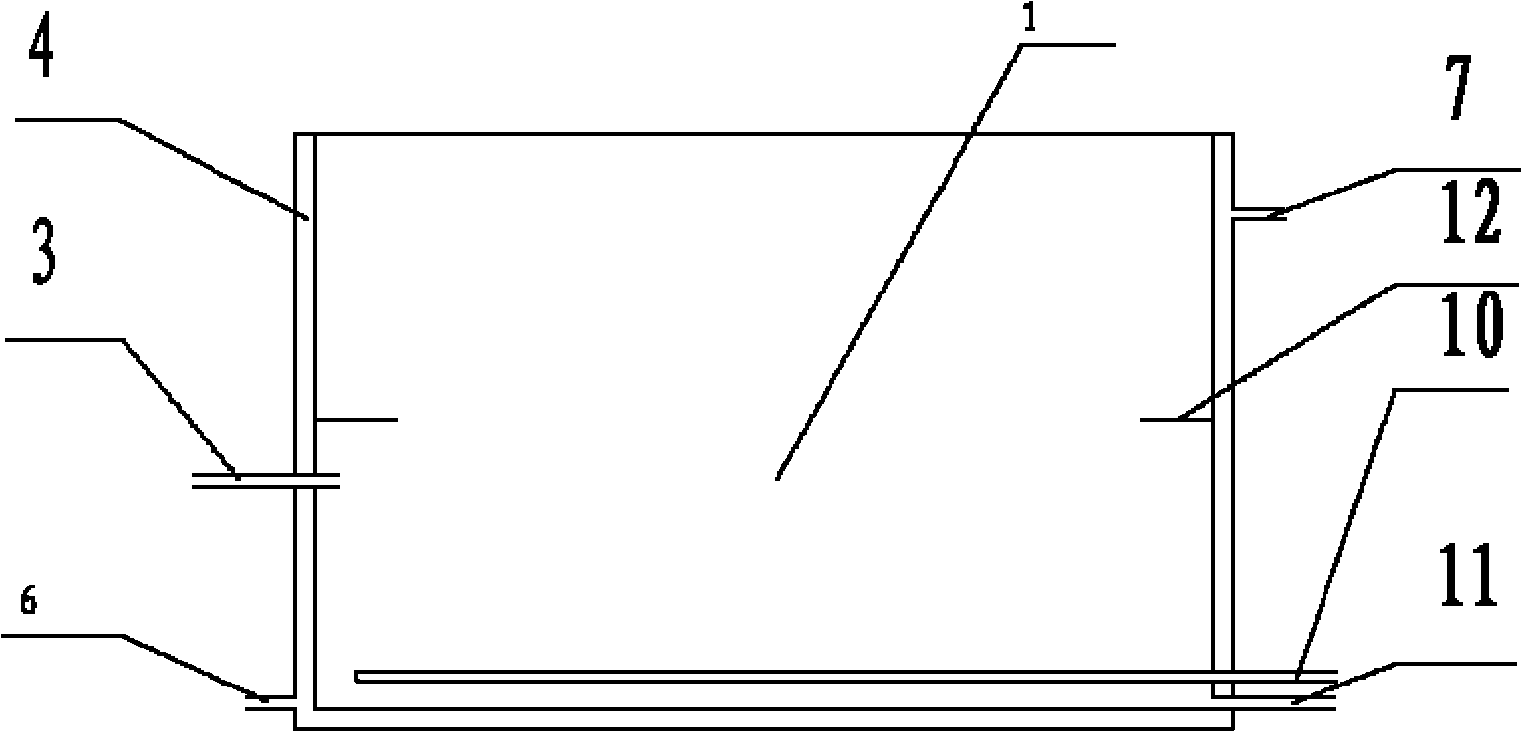

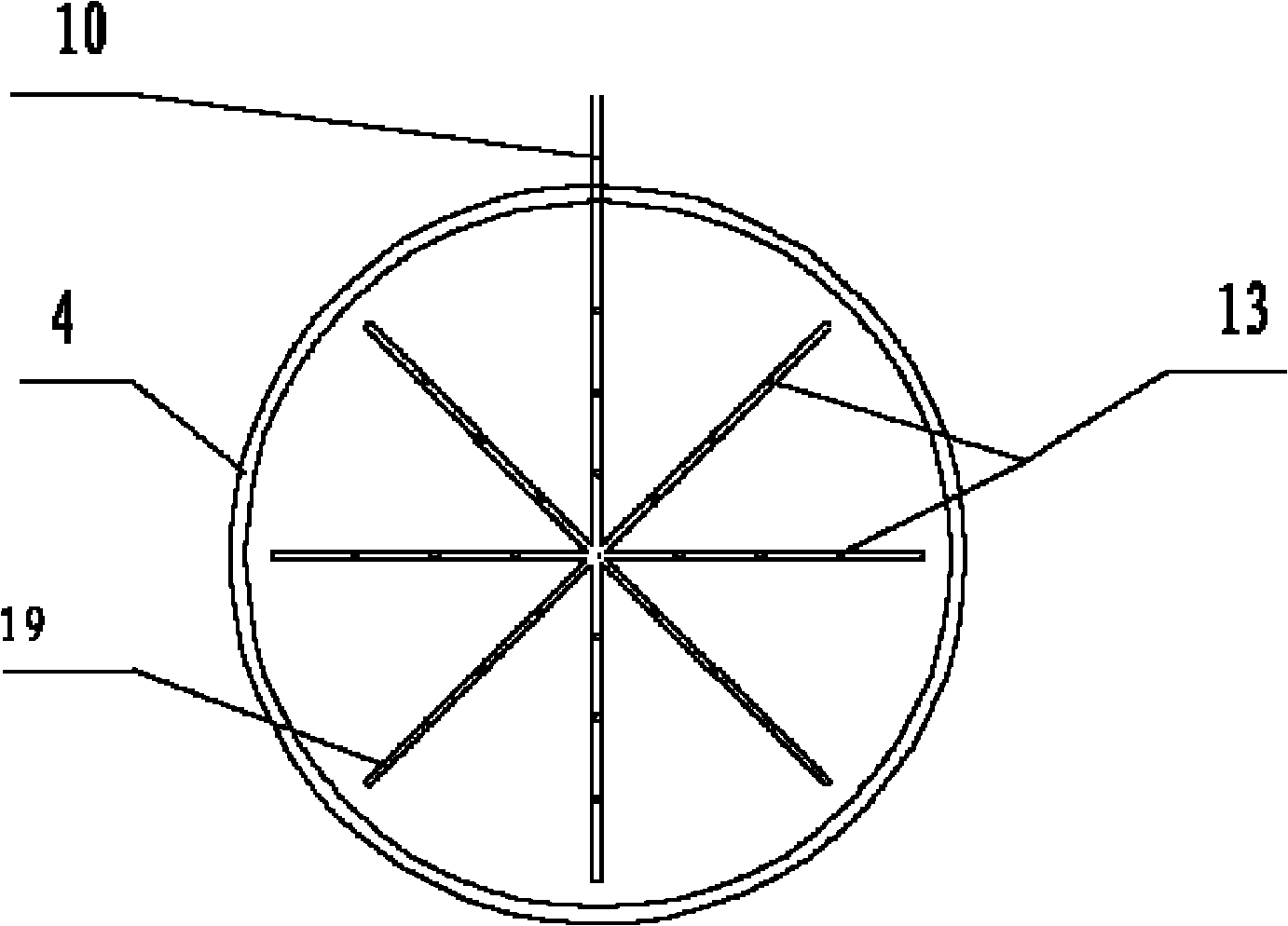

The invention relates to a ventilation-humidification coupled solid-state fermentation tank which comprises a main tank body the outer side of which is provided with a temperature control jacket, a tank cover and a material tube. The top surface of the tank cover is a screen mesh type tank cover surface, and the tank cover and the main tank body are fastened through a fastening buckle arranged at the edge of the top of the tank cover; a screen mesh type material tank bottom is arranged on a supporting ring stand and is provided with a first rubber ring washer for sealing; and a ventilation-humidification coupled unit is arranged at the bottom of the main tank body and comprises branched vent pipes, a sterilized water layer and vent pipes, and the branched vent pipes are distributed inside the sterilized water layer and are connected with the vent pipes. According to the solid-state fermentation device, the dust in the air is filtered off through introducing the air into the sterilized water layer, and the air containing water molecules is introduced into materials, so that air sterilization inside the tank is realized while the material humidity is maintained, and the redundant heat generated during the solid state-fermentation is dissipated; solid-state fermentation of aerobic bacteria is realized; and the ventilation humidification coupled solid-state fermentation tank has the advantages of novel principle, simple structure and low manufacturing cost, and is convenient in operation, generalization and production.

Description

technical field [0001] The invention belongs to the field of microbial solid-state fermentation, and relates to a solid-state fermentation tank for aerobic bacteria and a fermentation process thereof. Background technique [0002] There are two main fermentation methods in industrial production: submerged liquid fermentation and solid-state fermentation. Among them, the submerged liquid fermentation method is the most important fermentation process, the technology is relatively mature, and it is widely used in industrial production. However, there are also disadvantages such as complex technological process, easy bacterial contamination, complex post-fermentation treatment, large discharge of three wastes, and low spore production rate. The solid-state fermentation with a long history has been paid attention to again. As a new industrial production method, modern solid-state fermentation has shown its unique advantages in production. Solid-state fermentation is the process...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C12M1/00

CPCC12M21/16C12M23/46C12M41/22

Inventor 弓爱君陈建帮邱丽娜曹艳秋原小涛柴成文叶亚平

Owner UNIV OF SCI & TECH BEIJING

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com