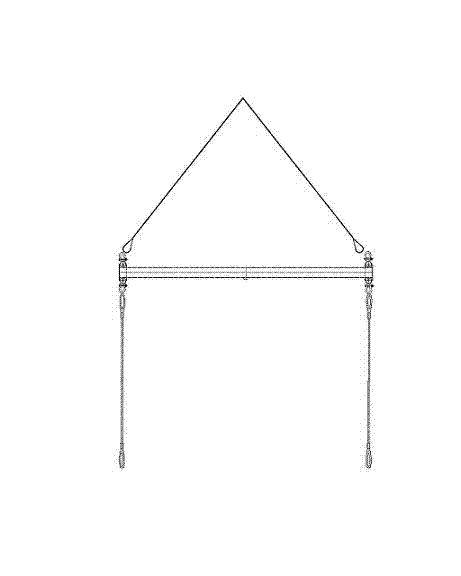

Hanging bar without shackle connection

A hanging bar and lifting lug technology, which is applied in the field of large-scale module hoisting engineering, can solve the problems of a large amount of manpower and material resources, reduce the service life of steel wire ropes, and creases of steel wire ropes, so as to achieve strong versatility, reduce assembly difficulty, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

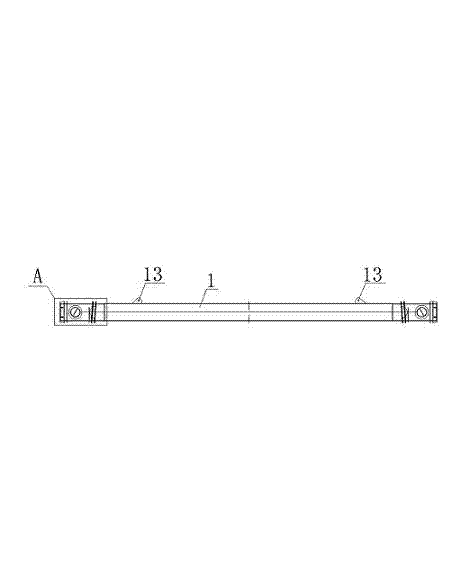

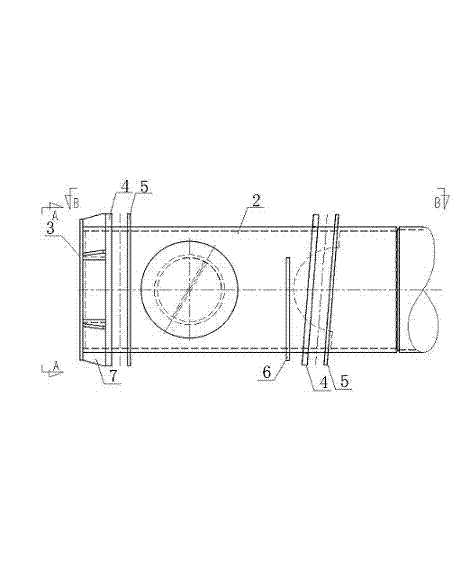

[0019] like figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown in the figure, the present invention does not require shackles to connect the suspension bars, and consists of a supporting beam 1, a main stress beam 2, a main beam end sealing plate 3, an outer resistance rope reinforcement ring plate 4, an inner resistance rope reinforcement ring plate 5, and a half reinforcement ring. Plate 6, Reinforcing bracket 7, Tubular lifting lug sealing plate 8, Tubular lifting lug longitudinal vertical plate 9, Tubular lifting lug main beam 10, Tubular lifting lug horizontal vertical plate 11, Main stress beam reinforcement vertical plate 12 13, the transport lifting lugs 13 are installed on both sides of the support beam 1, the outer side resistance rope reinforcement ring plate 4, the inner side resistance rope reinforcement ring plate 5 and the half reinforcement ring plate 6 are installed on the main stress beam 2, The reinforcing vertical plate 12 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com