Method for accurately calibrating inclination of vertical milling head of milling machine by using dialgauge

A technology of vertical milling head and dial indicator, which is applied in the direction of milling machine equipment, milling machine equipment details, precision positioning equipment, etc., can solve the problems of delaying production trial production tasks, increasing workpiece processing costs, and prolonging the processing cycle, so as to shorten the production cycle, The effect of reducing production costs and widely promoting application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

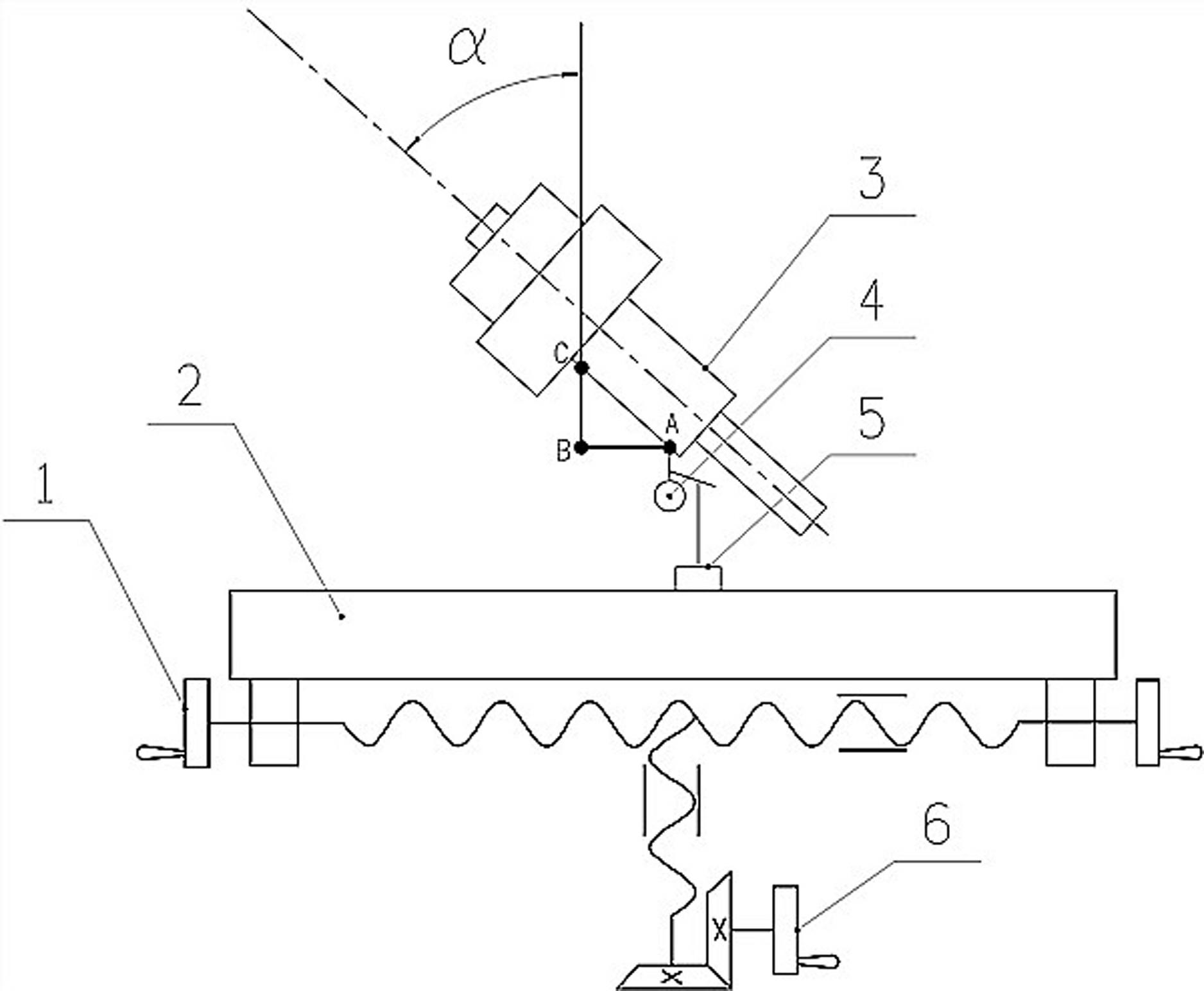

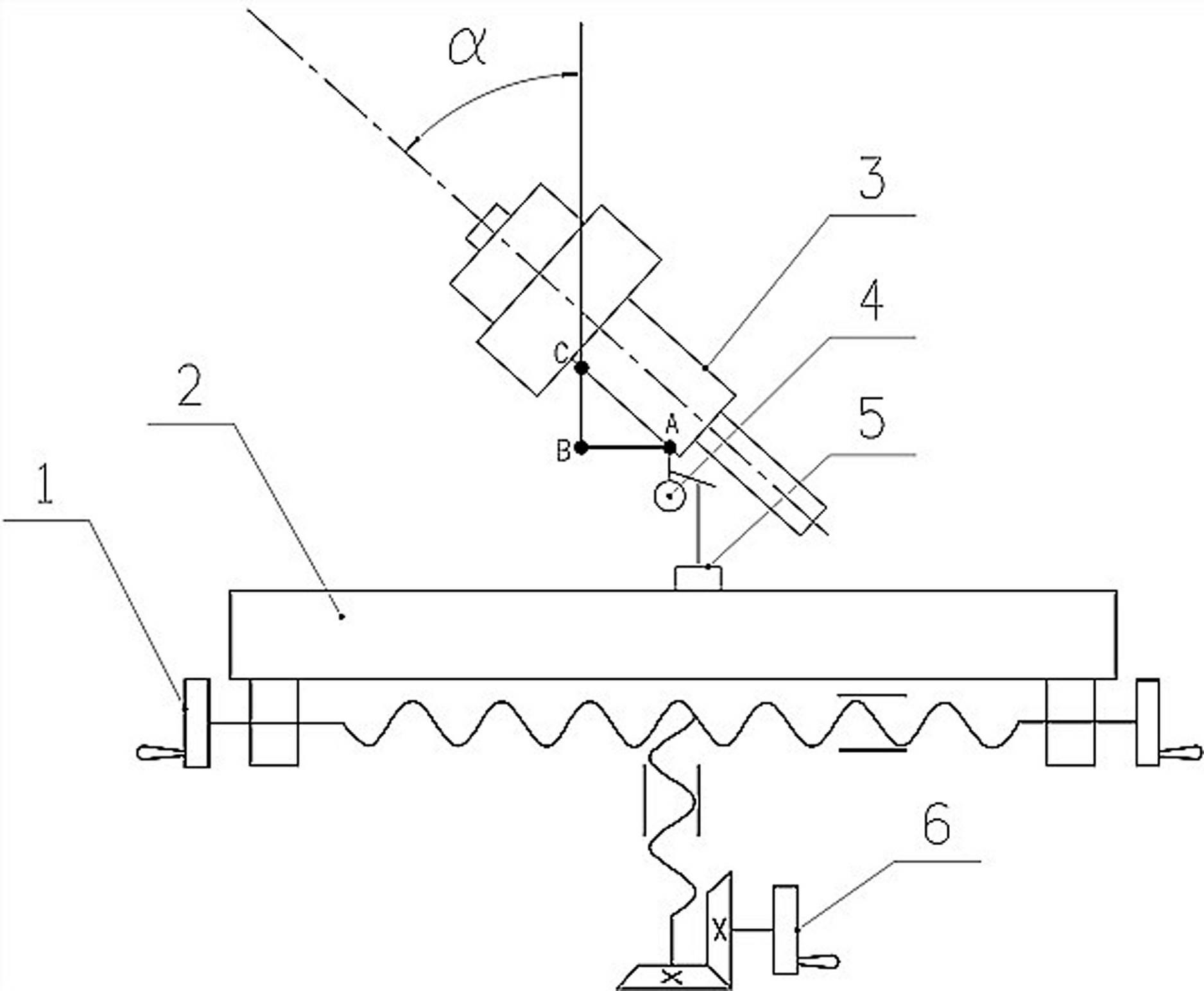

[0016] The invention uses a dial indicator to accurately correct the inclination angle of the end milling head of the milling machine. This embodiment takes the processing of precision inclined planes or oblique holes as an example. First of all, do the preparatory work, set the deflection angle of the end milling head 3 as α according to the inclined surface or inclined hole of the workpiece to be processed, and then deflect the end milling head 3 of the milling machine corresponding to the set angle α, and set the actual deflection angle as α ', then fix the dial indicator 4 on the workbench 2 of the milling machine through the magnetic gauge base 5, and shake the feed mechanism of the milling machine workbench 2 so that the contact of the dial indicator 4 presses against the outer wall of the end milling head 3 , and take this point as the starting point A. After the preparation work is completed, shake the horizontal feed mechanism 1 of the worktable 2 to move the dial in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com