Self-propelled tobacco seedling leaf cutting equipment

A self-propelled, tobacco seedling technology, applied in the field of agricultural engineering, can solve the problems of easy deviation, low straightness, low work efficiency, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

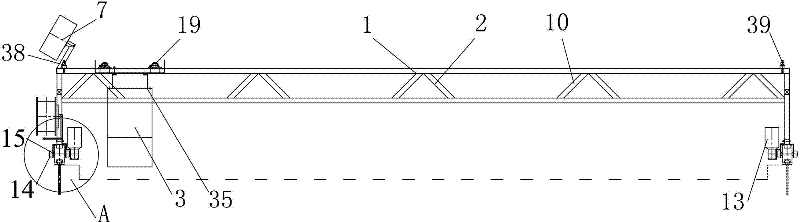

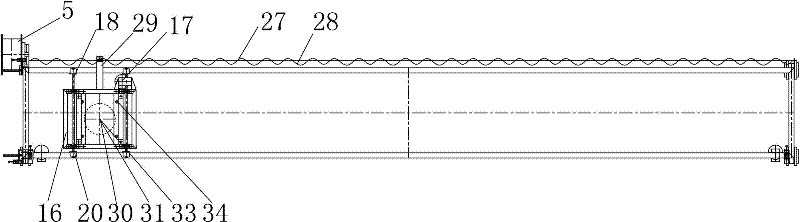

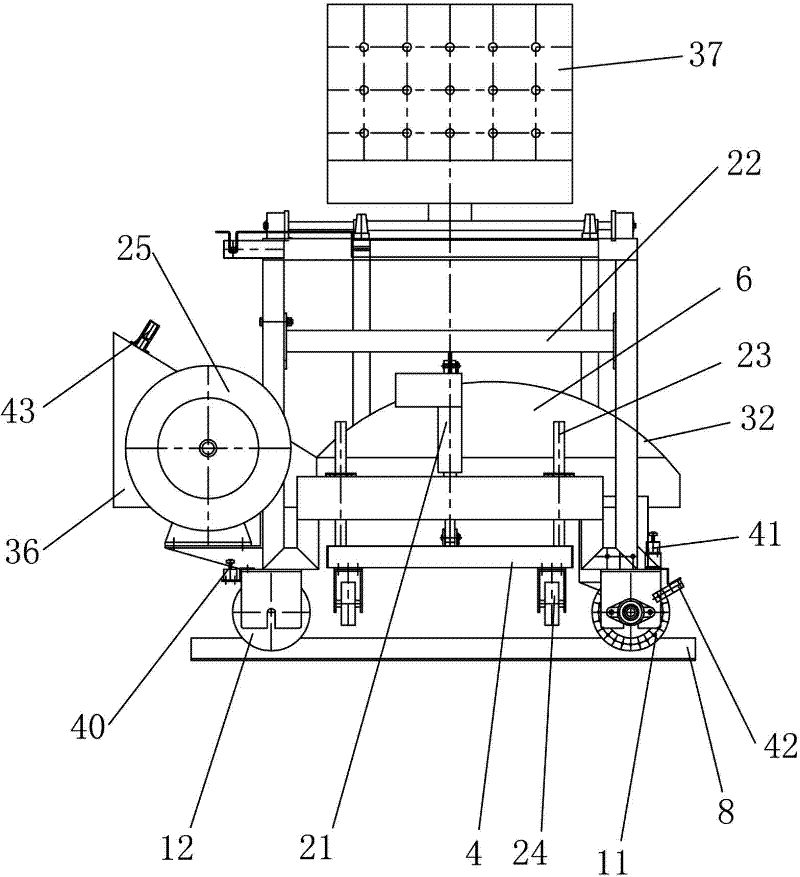

[0035] refer to Figure 1 to Figure 5 As shown, the self-propelled tobacco seedling leaf cutting equipment 1 of the present invention includes a frame assembly 2 and a leaf cutting trolley arranged on the frame assembly. The frame assembly 2 includes vertical support frames at both ends and a pair of frame beams ; It also includes a control system that can realize the regulation and control of the operation of various electrical components, which is centrally placed in a control cabinet 7 and can be fixed on the frame 2 through brackets, bolts and nuts respectively.

[0036]The innovation of the present invention is: a pair of mutually parallel leaf cutter moving tracks 8 are fixed at both ends of the greenhouse tobacco seedling culture liquid pool, see Figure 6 As shown, the moving track 8 of the leaf cutter can be fixed at both ends of the greenhouse tobacco seedling culture liquid pool by welding. Design a frame assembly, a pair of driving wheels 11 and a pair of driven w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com