De-painting kiln for pop can

A technology for cans and paint removal, which is applied to furnaces, lighting and heating equipment, furnace types, etc., can solve the problems of difficult mechanical automation continuous production lines, the inability to guarantee 100% paint removal of aluminum, and the influence of paint removal rate, etc., to achieve a simple structure , low cost and high paint removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

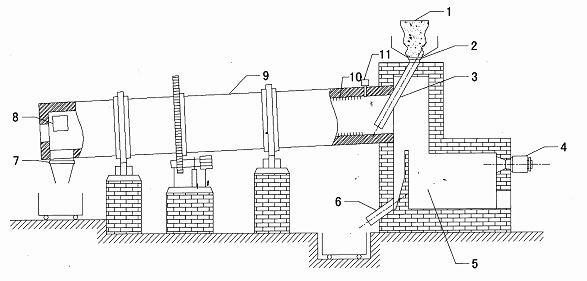

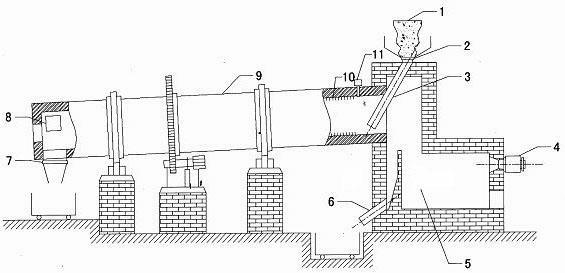

[0014] The present invention will be described in detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0015] The present invention is made up of combustion chamber 5, feeding device, paint stripping roller 9 and tail discharge device 7.

[0016] The chamber of the combustion chamber 5 is composed of an upper chamber and a lower chamber, and the lower chamber is a combustion zone. The combustion chamber 5 is provided with a burner 4 and a discharge pipe 6. The burner 4 directly burns fuel to provide thermal energy, and the discharge pipe 6 can The scattered debris from the feed and discharge of the paint stripping kiln is discharged; the temperature of the combustion chamber 5 is controlled within the range of 760°C-800°C. Emergency pressure relief when under pressure. The upper chamber is a thermal energy supply chamber, which is directly connected to the paint stripping roller 9. This design realizes heating without naked f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com