Surface sizing agent as well as preparation method and application thereof

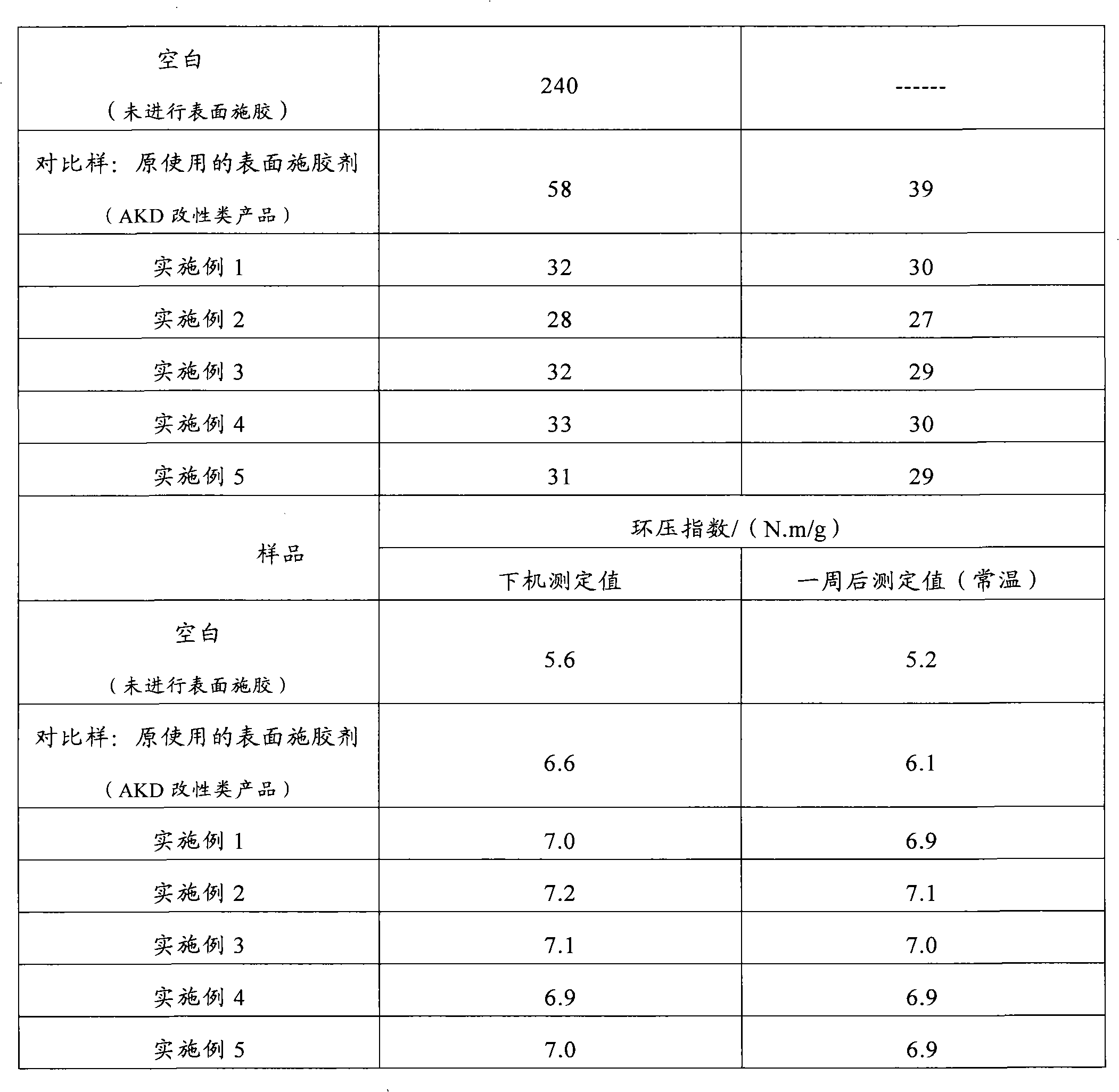

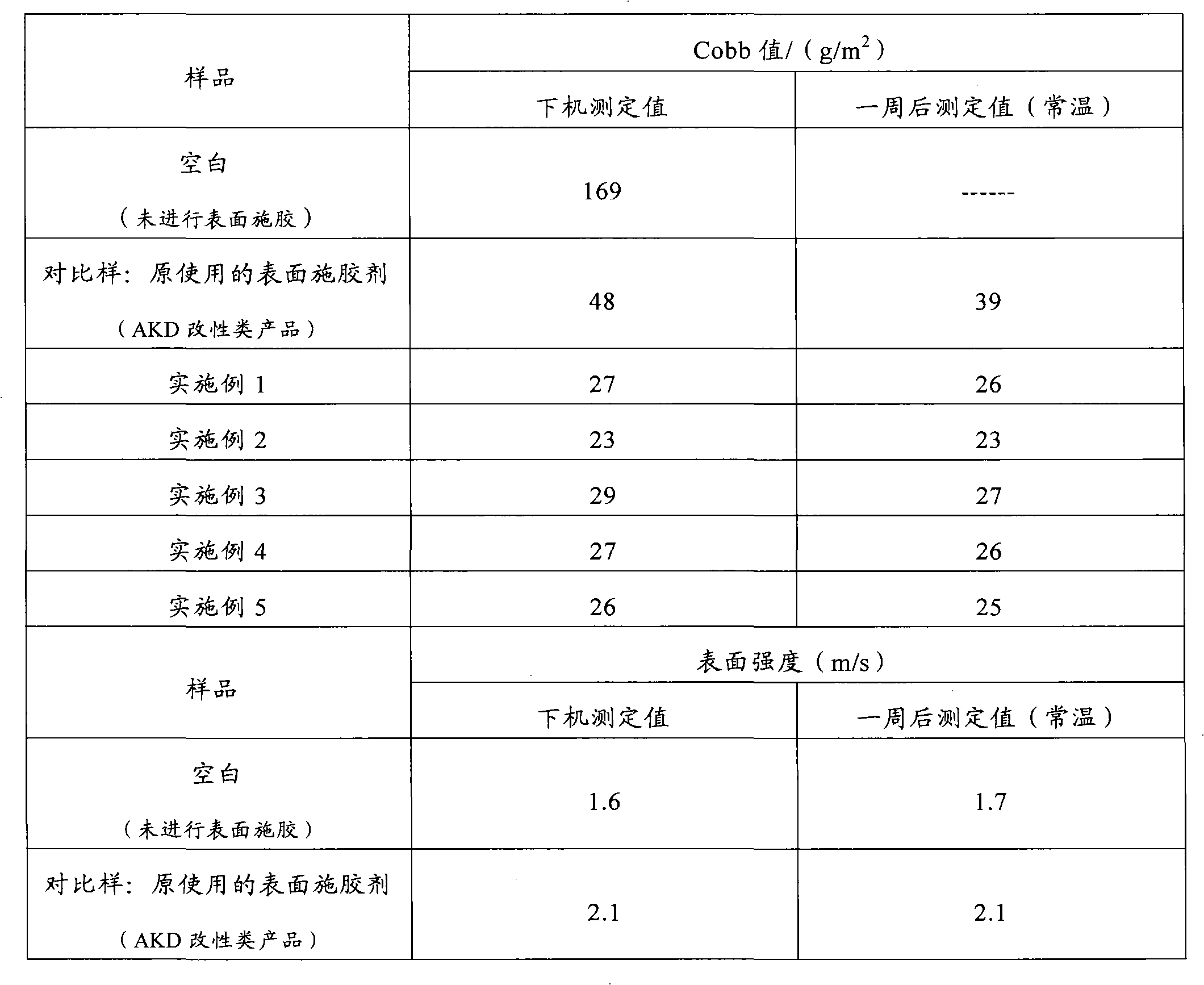

A technology of surface sizing agent and dispersant, which is applied in the direction of water-repellent addition, textile and papermaking, coating, etc. It can solve the problems of dampness, slow curing, large loss, etc., and achieve the purpose of improving ring compressive strength, improving surface strength, Good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 25kg of gelatin with a molecular weight of 20000g / mol in the reaction tank, add 500kg of deionized water, heat to 85°C with steam until the gelatin dissolves in deionized water, add 300kg of deionized water to cool down to 45°C, add 30kg of octamethyl Cyclotetrasiloxane, adding 1.5kg concentration of 25wt% 16 alkyltrimethylammonium chloride aqueous solution as an emulsifier, heating to 95°C with steam again, adding 1kg concentration of 20% ammonium persulfate by weight The aqueous solution is used as the initiator, and then other components are added sequentially, including 75kg of styrene, 3kg of dimethyl diallyl ammonium chloride, 3kg of aminopropyl acrylate, and 20kg of propyl methacrylate, and the addition is completed within 1 hour After that, keep warm at 95°C for 1 hour, cool to 35°C, and filter through a 100-mesh filter to complete 1 # The product is produced with a pH value of about 3 and a solid content of 15±1wt%.

Embodiment 2

[0048] Add 25kg of gelatin with a molecular weight of 50000g / mol in the reaction tank, add 500kg of deionized water, heat to 85°C with steam until the gelatin dissolves in deionized water, add 300kg of deionized water to cool down to 45°C, add 35kg of octamethyl Cyclotetrasiloxane, adding 1.5kg concentration of 25wt% 18 alkyltrimethylammonium chloride aqueous solution as an emulsifier, heating to 95°C with water vapor again, adding 1kg concentration of 20wt% ammonium persulfate aqueous solution as trigger Then add other components sequentially, including styrene 75kg, dimethylaminoethyl methacrylate chloride 3kg, methacrylamide 3kg, ethyl methacrylate 20kg, after adding in succession within 1 hour, Then keep warm at 95°C for 1 hour, cool to 35°C, and filter through a 100-mesh filter to complete 2 # The product is produced with a pH value of about 3 and a solid content of 15±1wt%.

Embodiment 3

[0050] Add 35kg of gelatin with a molecular weight of 20000g / mol in the reaction tank, add 500kg of deionized water, heat to 85°C with water steam until the gelatin dissolves, add 300kg of deionized water and cool down to 45°C, add 40kg of hexamethylcyclotrisiloxane alkane, adding 0.5kg concentration is 25wt% aqueous solution of 16 alkyltrimethylammonium chloride as emulsifier, water vapor heating to 95°C again, adding 0.8kg concentration is 20wt% sodium persulfate aqueous solution as initiator, and then Add other components sequentially, including 74kg of styrene, 5kg of dimethyl diallyl ammonium chloride, 1kg of glycidyl acrylate, and 15kg of isobutyl methacrylate. Insulate for 1 hour, cool to 35°C, filter through a 100-mesh filter, and complete 3 # The product is produced with a pH value of about 3 and a solid content of 15±1wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com