Biological constant temperature separating tank and separating method thereof

A separation tank and constant temperature technology, applied in the direction of fermentation, etc., can solve the problems of extractant toxicity, retention, real-time extraction without fermentation, etc., and achieve the effects of simplifying the extraction steps, ensuring the activity of acid production, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

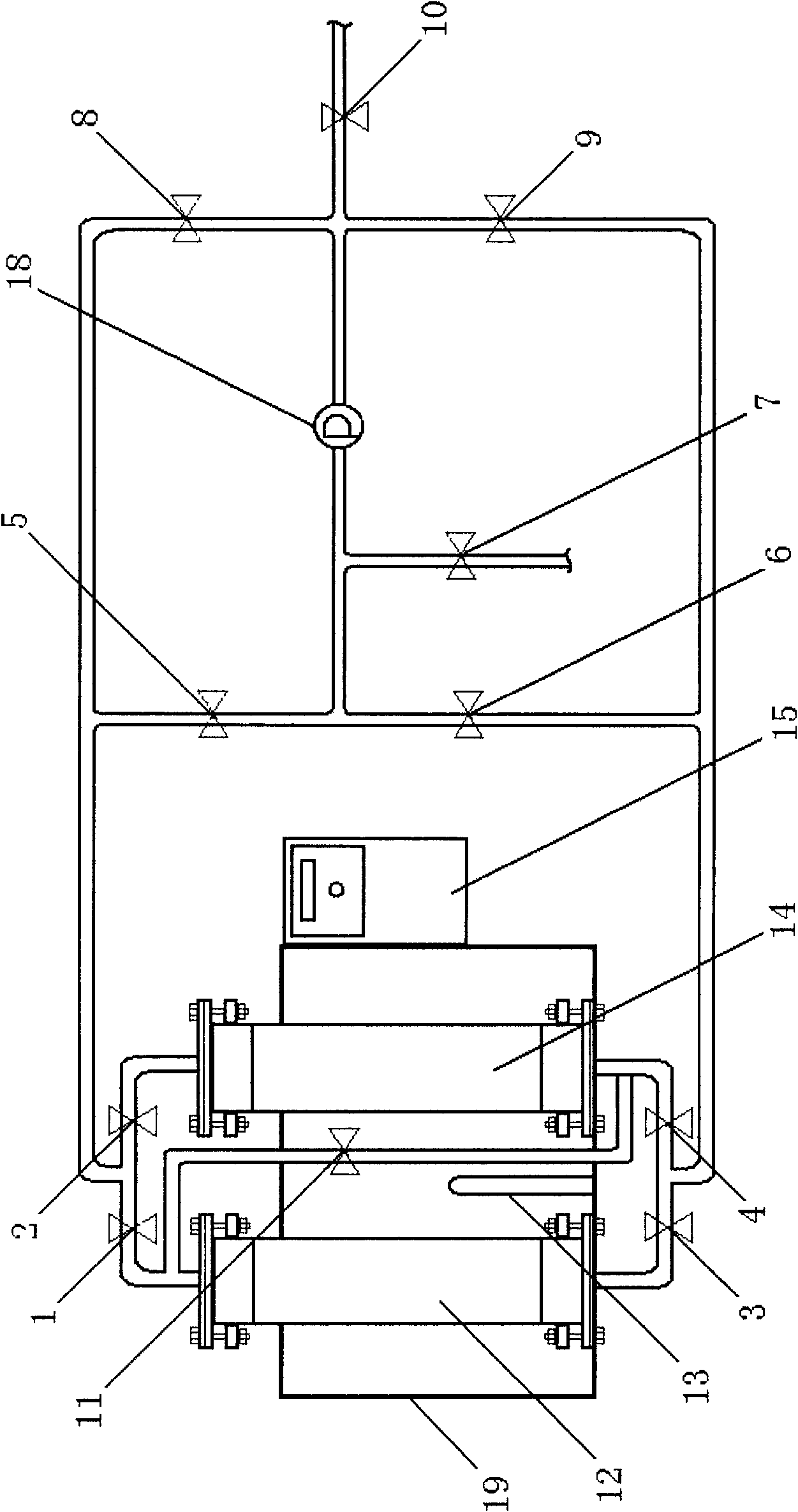

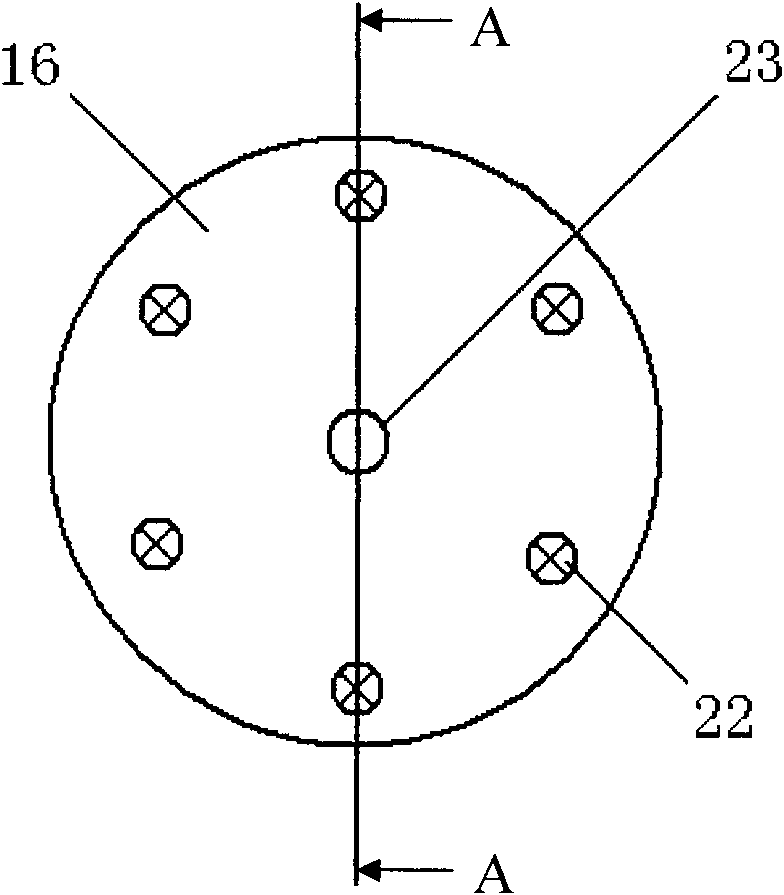

[0036] figure 1 It is a structural schematic diagram of the biological constant temperature separation tank of the present invention. Such as figure 1 Shown, the biological constant temperature separation tank of the present invention comprises the plexiglass tube (12) and the plexiglass tube (14) that are placed in the water tank (19), a U-shaped heater (13) that is positioned at the bottom center of the water tank, a The water tank (19) is connected with a thermostat (15) for controlling the temperature in the water tank, a pump (18) and several pipelines providing flow paths for the fermented liquid, and a plurality of valves for controlling the flow direction of the fermented liquid are arranged in the middle of the pipelines. The plexiglass tube (12) and the plexiglass tube (14) are arranged on both sides of the heater (13), and the ple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com