Silk polished lacquer painting and preparation method thereof

A technology of silk and lacquer painting, applied in the field of silk lacquer painting and its preparation, can solve the problems of difficult large-scale works and difficult quantitative production of lacquer painting, so as to reduce production costs, broad market development and application prospects, and shorten the production process. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

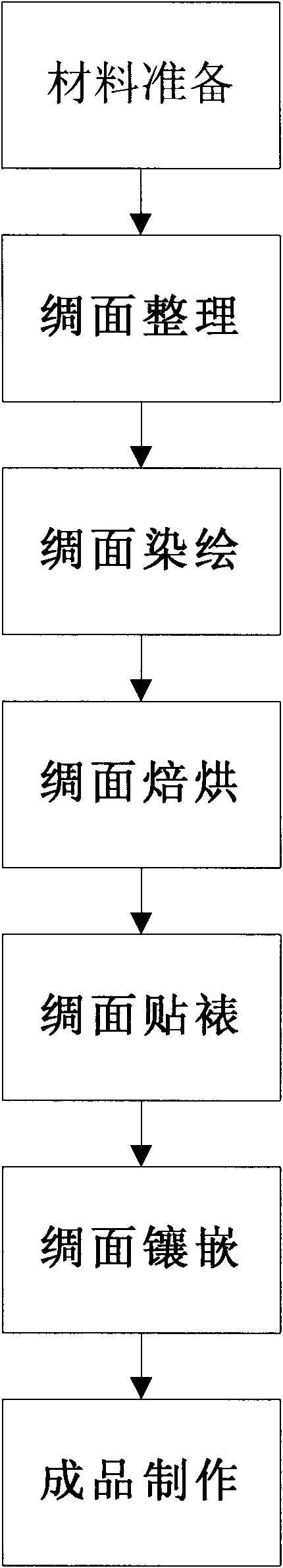

[0043] Embodiment 1 silk grinding lacquer painting process

[0044] Material preparation: silk fabrics, pearl powder, quartz powder, glass reflective powder, pigments, acid dyes, water-based adhesives, transparent paints, and oil-based dyes, suitable for the original lacquer painting process such as inlaying, inlaying, pasting, Carved and other raw and auxiliary materials.

[0045] Finishing of silk surface: first make 12515 crepe de chine waterproof and stiff;

[0046] Dyeing and painting of silk surface: according to the screen requirements of the design creation, first use water-based adhesives and pearl powder, quartz powder, glass reflective powder, pigments, acid dyes to prepare water-based color paste; then use oil-based transparent lacquer and pearl powder, quartz powder , glass reflective powder, pigments, etc. are prepared into oily color paste. Then it can be dyed and painted with water-based color paste alone, or it can be dyed and painted with oil-based color pa...

Embodiment 2

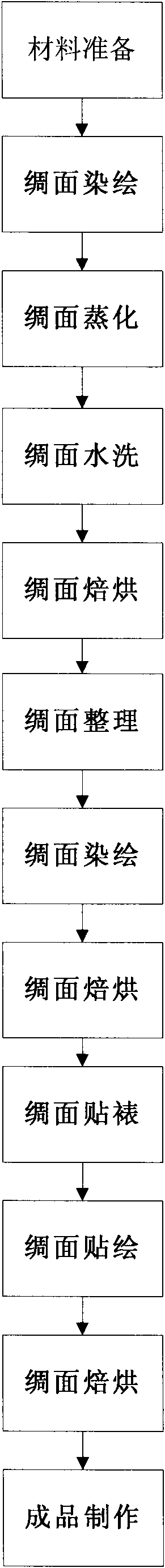

[0052] Embodiment 2 silk grinding lacquer painting process

[0053] Material preparation: silk fabrics, pearl powder, quartz powder, glass reflective powder, pigments, acid dyes, water-based adhesives, transparent paints, and oil-based dyes, suitable for the original lacquer painting process such as inlaying, inlaying, pasting, Carved and other raw and auxiliary materials.

[0054] Dyeing and painting of silk surface: dye and paint the silk surface with acid dyes on the whitened 14101 plain crepe satin by conventional hand-spraying, sprinkling, printing, and tie-dyeing techniques.

[0055] Steaming of silk noodles: steaming time 35min+ / -5min, steaming temperature 102℃+ / -2℃.

[0056] Silk surface washing: washing time 10min+ / -2min, washing temperature 80℃+ / -5℃.

[0057] Silk surface baking: baking time: 2min+ / -1min, baking temperature 110℃+ / -5℃.

[0058] Finishing of silk surface: make 14101 plain crepe satin waterproof and partial stiffening;

[0059] Dyeing and painting o...

Embodiment 3

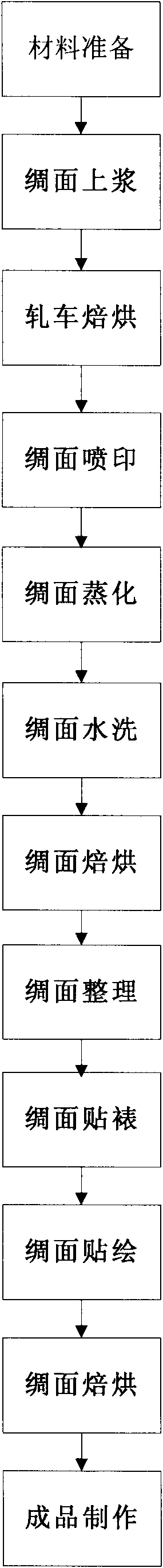

[0066] Embodiment 3 silk grinding lacquer painting process

[0067] Material preparation: silk fabrics, pearl powder, quartz powder, glass reflective powder, pigments, reactive dyes, water-based adhesives, transparent paints, and oily dyes, which are suitable for the production of original lacquer paintings such as inlaying, inlaying, pasting, Carved and other raw and auxiliary materials.

[0068] Sizing on silk surface: Squeeze and coat the paste for active printing on the surface of refined white 14101 plain crepe satin, or soak the plain crepe satin fabric in the paste for active printing, soaking time 10min+ / -2min, ensure that it is completely soaked, soaked The paste must be even.

[0069] Pad car baking: rolling stick speed 8m+ / -2m, baking temperature 102℃+ / -2℃.

[0070] Silk surface printing: Print the design draft on the plain crepe satin surface, dry or dry naturally.

[0071] Steaming of silk noodles: steaming time 15min+ / -2min, steaming temperature 102℃+ / -2℃.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com