Light guide plate, illuminating device and manufacturing method of light guide plate

A manufacturing method and lighting device technology, applied to lighting devices, fixed lighting devices, light guides of lighting systems, etc., can solve the problems of uneven surface light source and enlarged dark area, achieve uniform surface light source, simple manufacturing process, increase The effect of light output angle range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

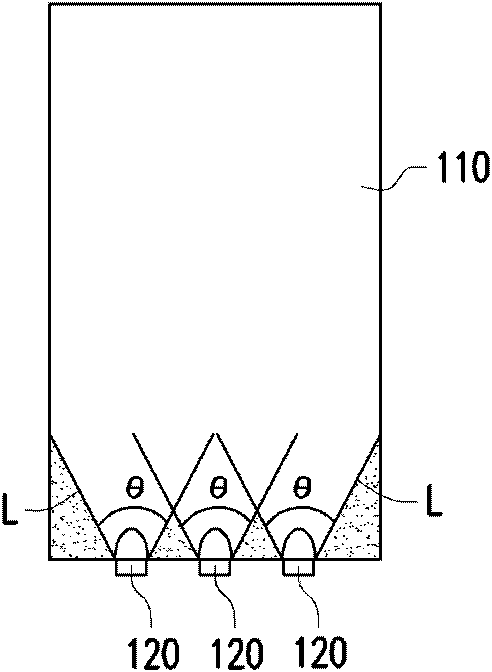

[0025] The invention provides a light guide plate, which can increase the light output angle range of a light source and reduce bright spots.

[0026] The invention provides a method for manufacturing a light guide plate, which can easily manufacture the above light guide plate.

[0027] The present invention provides an illuminating device, which can provide a uniform surface light source by using the above-mentioned light guide plate.

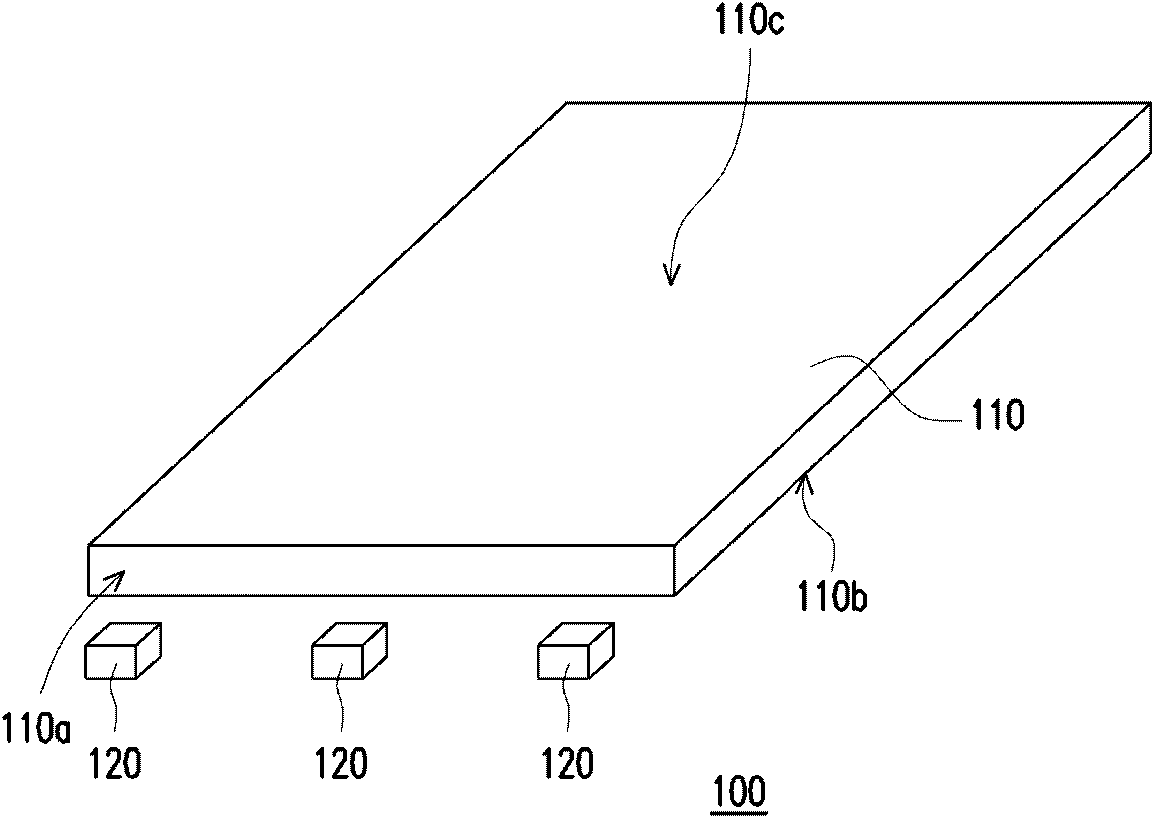

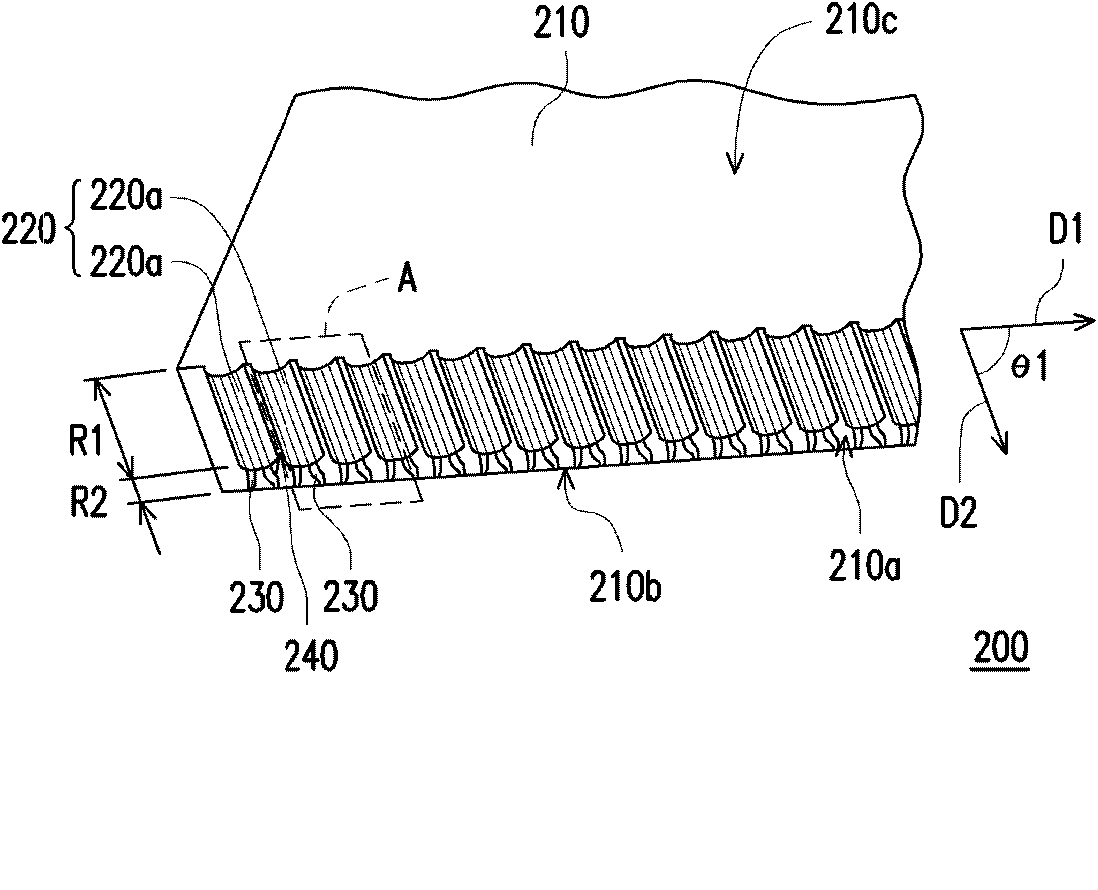

[0028] The invention proposes a light guide plate, including: a plate body, an array of optical elements and a plurality of optical strip structures. The plate body has a light incident surface. The light incident surface has an optical diffusion area and an edge area adjacent to the optical diffusion area. The optical element array is arranged in the optical diffusion area. The optical strip structure is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com