Package carrier

A carrier and light-carrying technology, which is applied in lighting devices, semiconductor devices, semiconductor devices of light-emitting elements, etc., can solve the problems of limited light-emitting angle and inability to have a light-emitting angle, and achieve the effect of increasing the range of light-emitting angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

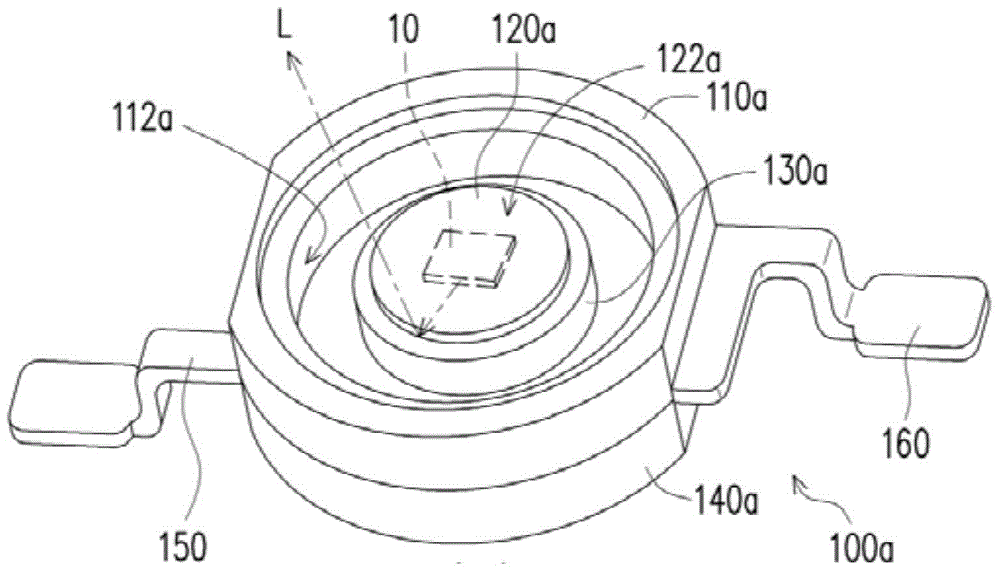

[0030] figure 1 It is a three-dimensional schematic diagram of a package carrier according to an embodiment of the present invention. Please refer to figure 1 , in this embodiment, the packaging carrier 100a is suitable for carrying at least one light emitting unit 10 ( figure 1 Only one is shown schematically). The packaging carrier 100a includes an annular shell 110a and a light-transmitting light-guiding carrier 120a. The annular housing 110a has a groove 112a. The light-transmitting light-guiding stage 120a is disposed in the groove 112a of the annular housing 110a, wherein the light-emitting unit 10 is adapted to be arranged on the light-transmitting light-guiding stage 120a, and the horizontal projected area of the light-transmitting light-guiding stage 120a is larger than the light-emitting The horizontal projected area of unit 10. The light beam L emitted by the light emitting unit 10 enters the light-transmitting light-guiding carrier 120a, and exits from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com