a range hood

A technology for range hoods and fans, which is applied in the direction of removing oil fume, mechanical equipment, machines/engines, etc., and can solve problems such as inability to achieve sealing effect, pollution of parts, and simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

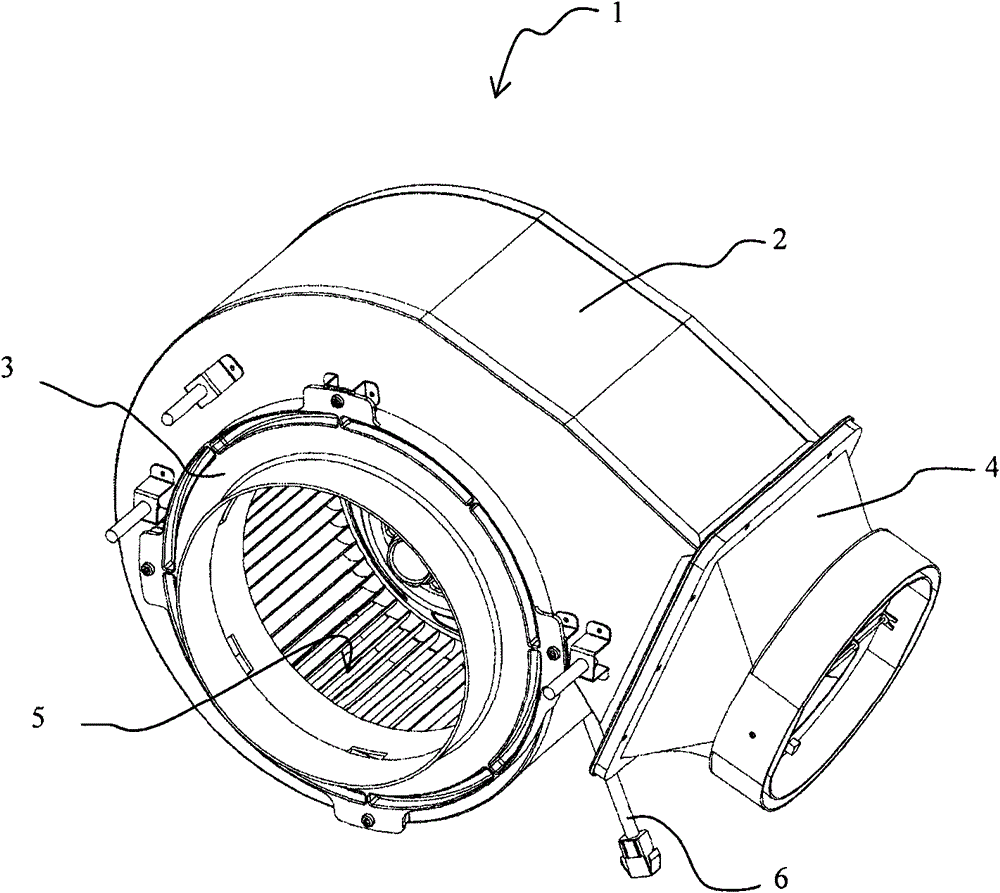

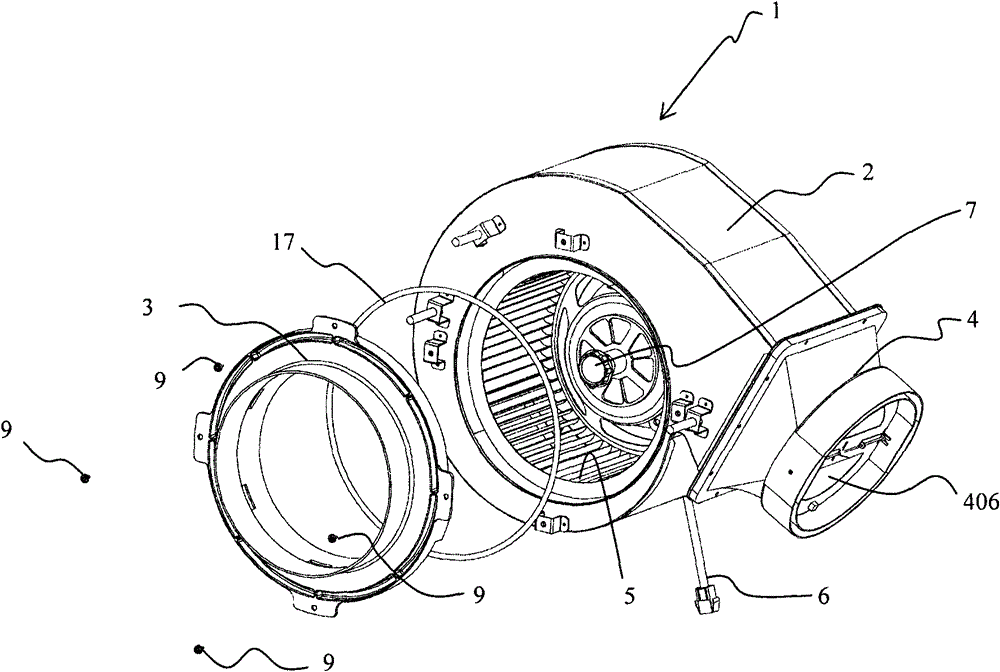

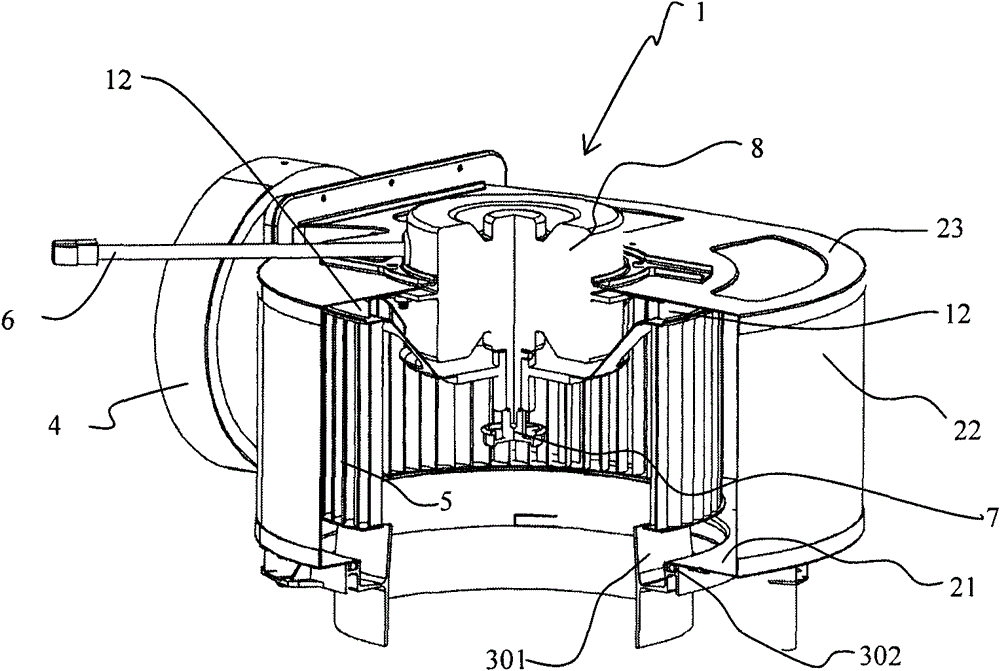

[0017] See attached Figures 1 to 5 , a range hood of the present invention, which is not shown in the figure, includes a fan system 1 that provides operating airflow power for the entire range hood. The fan system 1 is connected to an external power source of the range hood through a power cord 6 to supply power to a motor 8 as a power source. See attached image 3 , a cross-sectional view of the fan system 1, the impeller 5 is driven by a motor 8 to generate an operating airflow. The impeller 5 and the motor 8 are connected together by bolts 7 . The fan system 1 also includes fan components for housing the impeller 5 . The blower component includes a volute casing 2 and an air inlet pipe base 3 connected thereto. A sealing ring 17 made of elastic material is arranged between the volute casing 2 and the air inlet pipe base 3 connected thereto. The air inlet pipe base 3 has an air outlet end, and a sealing ring receiving groove 302 is arranged on the air outlet end. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com