Dual-membrane processing system and method for micro-polluted raw water

A technology of treatment system and treatment method, which is applied in the field of drinking water treatment system, can solve the problems that it is difficult to control biological pollutants such as bacteria, cannot guarantee the biological safety of water quality, and the instability of effluent water quality, so as to improve biological safety, The effect of small footprint and energy saving in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

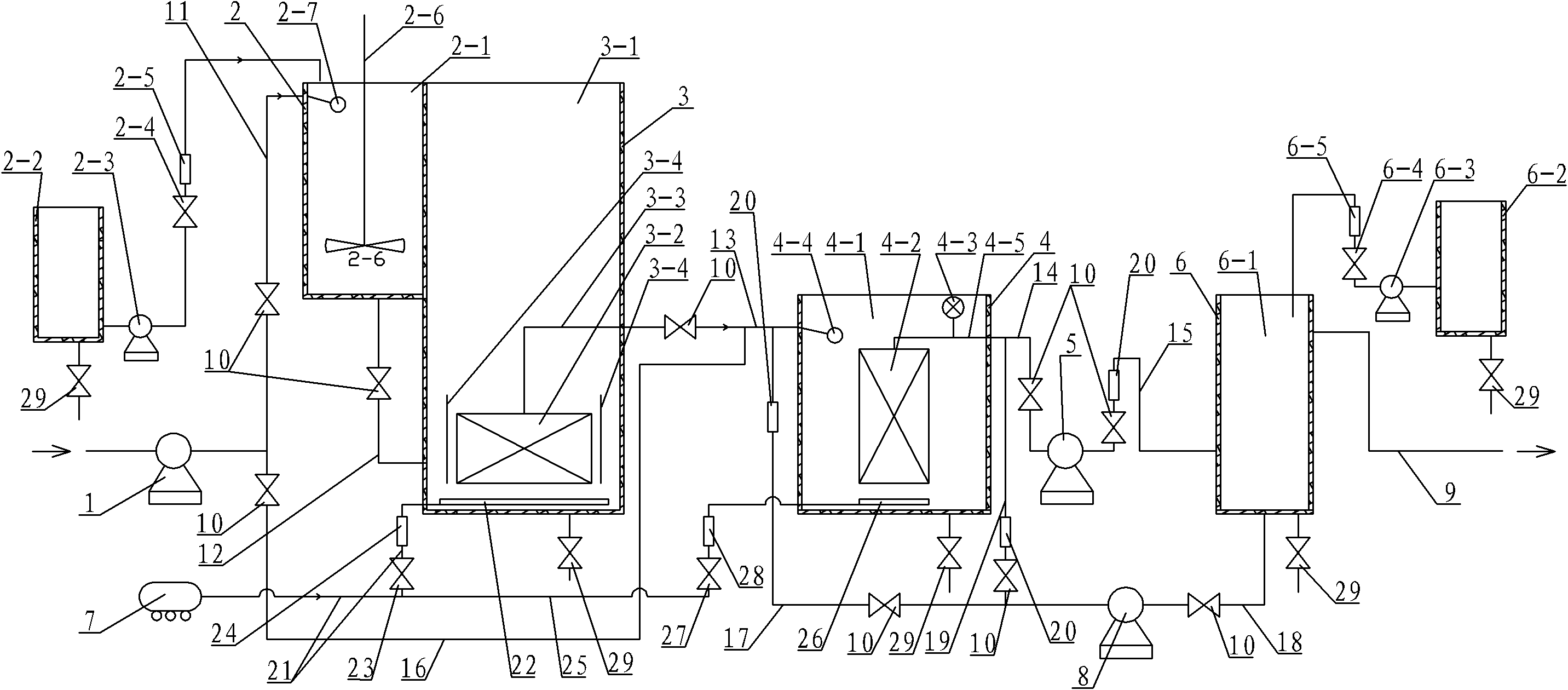

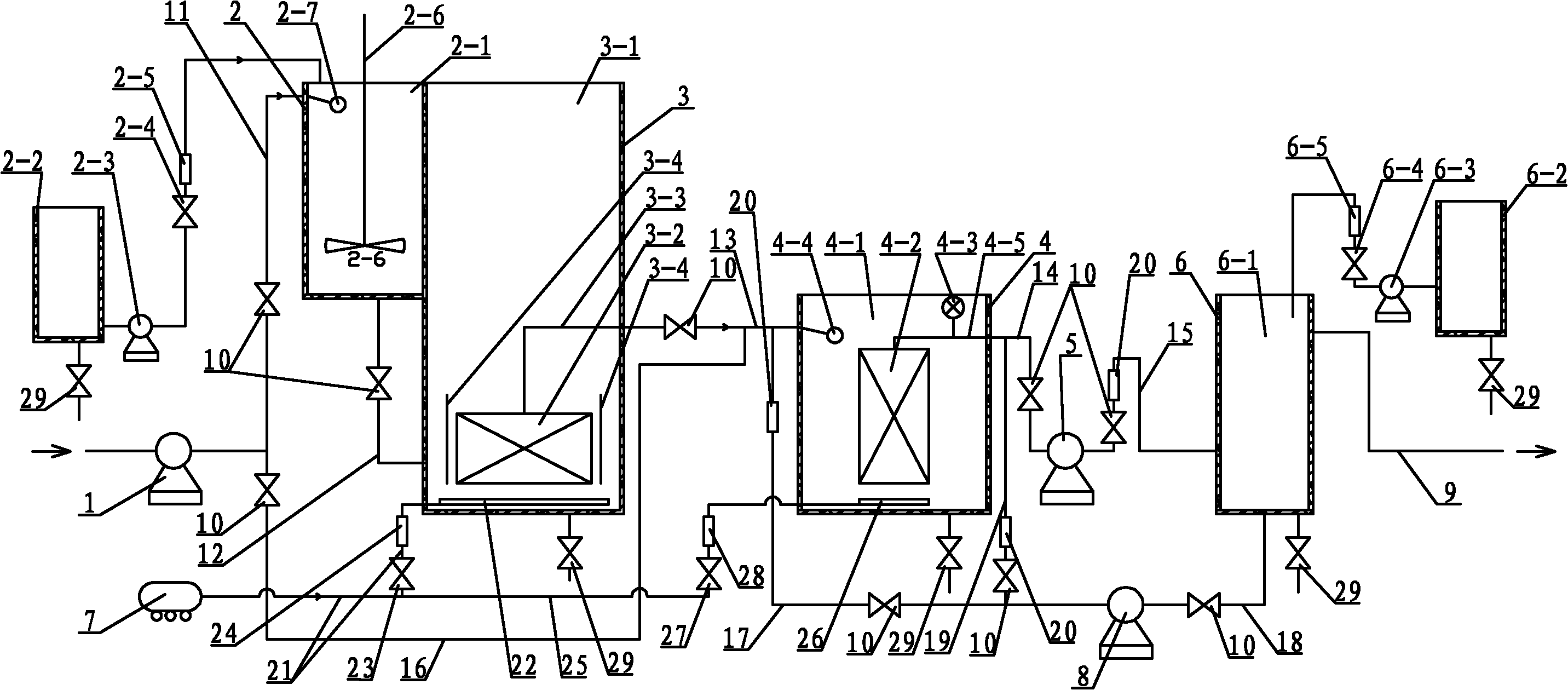

[0014] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a raw water lift pump 1, a mixing assembly 2, a microfiltration membrane separation assembly 3, an ultrafiltration membrane separation assembly 4, a self-priming pump 5, a clear water assembly 6, a backwash pump 8, an outlet pipe 9, The first pipeline 11, the second pipeline 12, the third pipeline 13, the fourth pipeline 14, the fifth pipeline 15, the sixth pipeline 16, the seventh pipeline 17, the eighth pipeline 18, the ninth pipeline pipeline 19, three water flowmeters 20 and several control valves 10, the mixing assembly 2 is composed of a mixing tank 2-1, a medicine storage tank 2-2, a medicine adding pump 2-3, a medicine adding valve 2-4, Composed of dosing flowmeter 2-5, agitator 2-6 and reaction liquid float valve 2-7, medicine storage pool 2-2 passes through dosing pump 2-3, dosing valve 2-4, dosing flowmeter 2- 5 communicates with the mixing pool 2-1, the agi...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 1 To describe this embodiment, the height of the microfiltration membrane separation tank 3-1 of this embodiment is 3 meters to 4 meters, and the average water pressure of the microfiltration membrane module 3-2 is 20KPa to 30KPa. This design enables the microfiltration membrane separation tank 3-1 to discharge water by its own weight, saving energy consumption. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 1 To describe this embodiment, the microfiltration membrane in the microfiltration membrane module 3-2 of this embodiment is a hollow fiber membrane with a pore size of 0.1 micron to 1 micron. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0017] Specific implementation mode four: combination figure 1To illustrate this embodiment, the ultrafiltration membrane in the ultrafiltration membrane module 4-2 of this embodiment is a hollow fiber membrane, and its pore size is 0.01 micron to 0.1 micron. Other components and connections are the same as those in the third embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com