Packaging box turnover mechanism

A turning mechanism and packaging box technology, applied in packaging and other directions, can solve the problems of large wear on the surface of the packaging box, low turning efficiency, and failure to meet high-end customers, so as to maintain the appearance quality and high turning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below with reference to the drawings and embodiments.

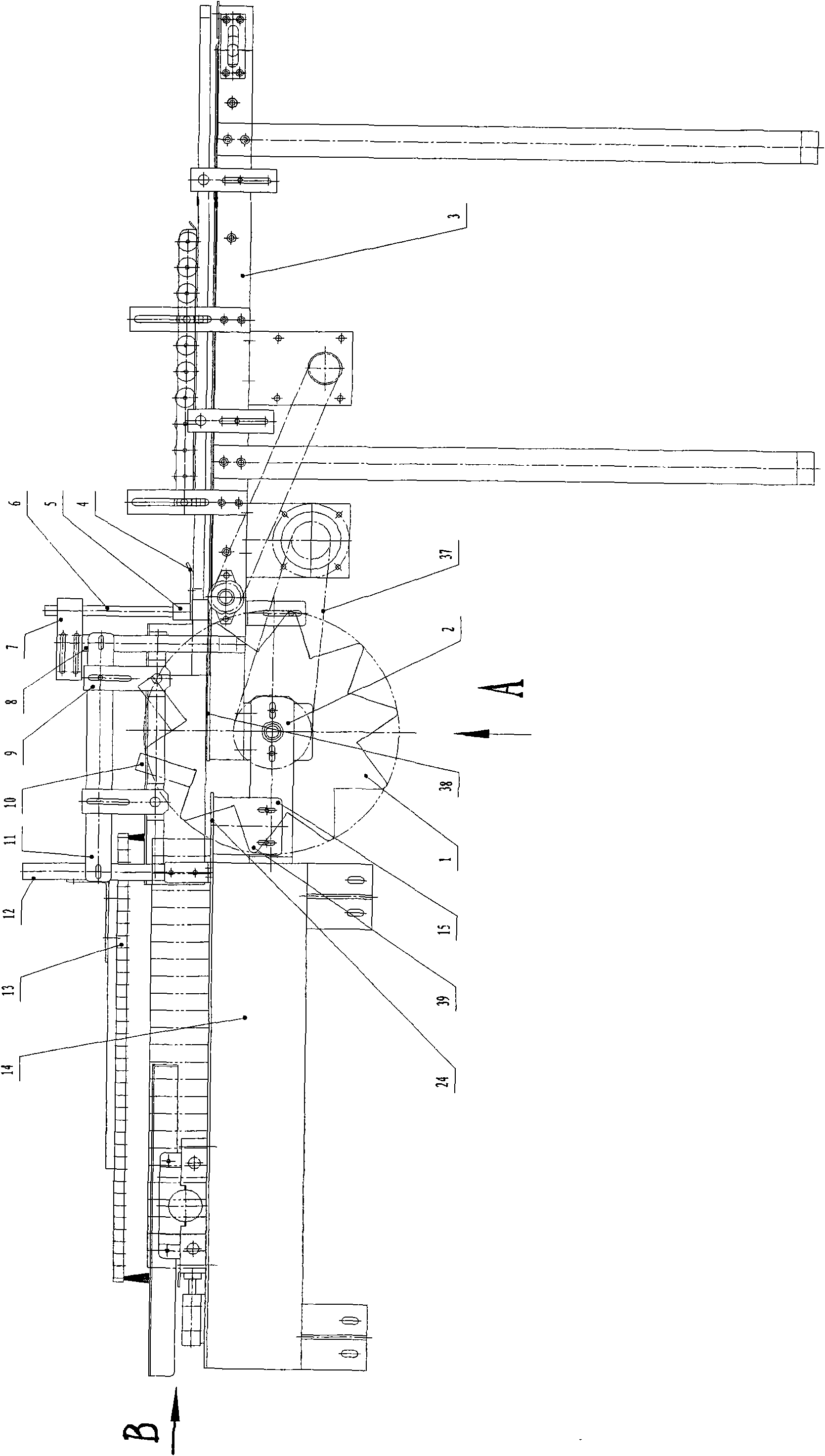

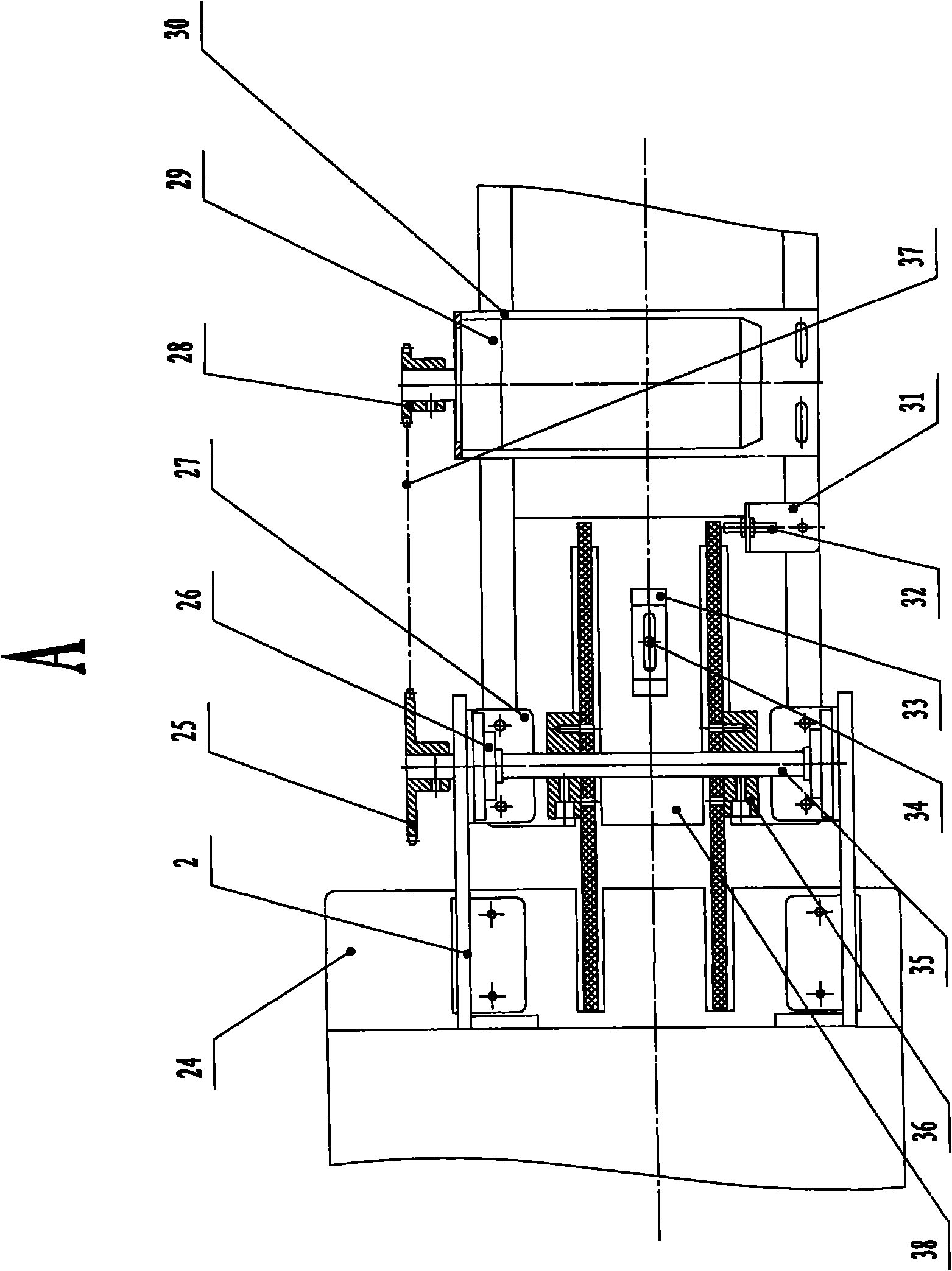

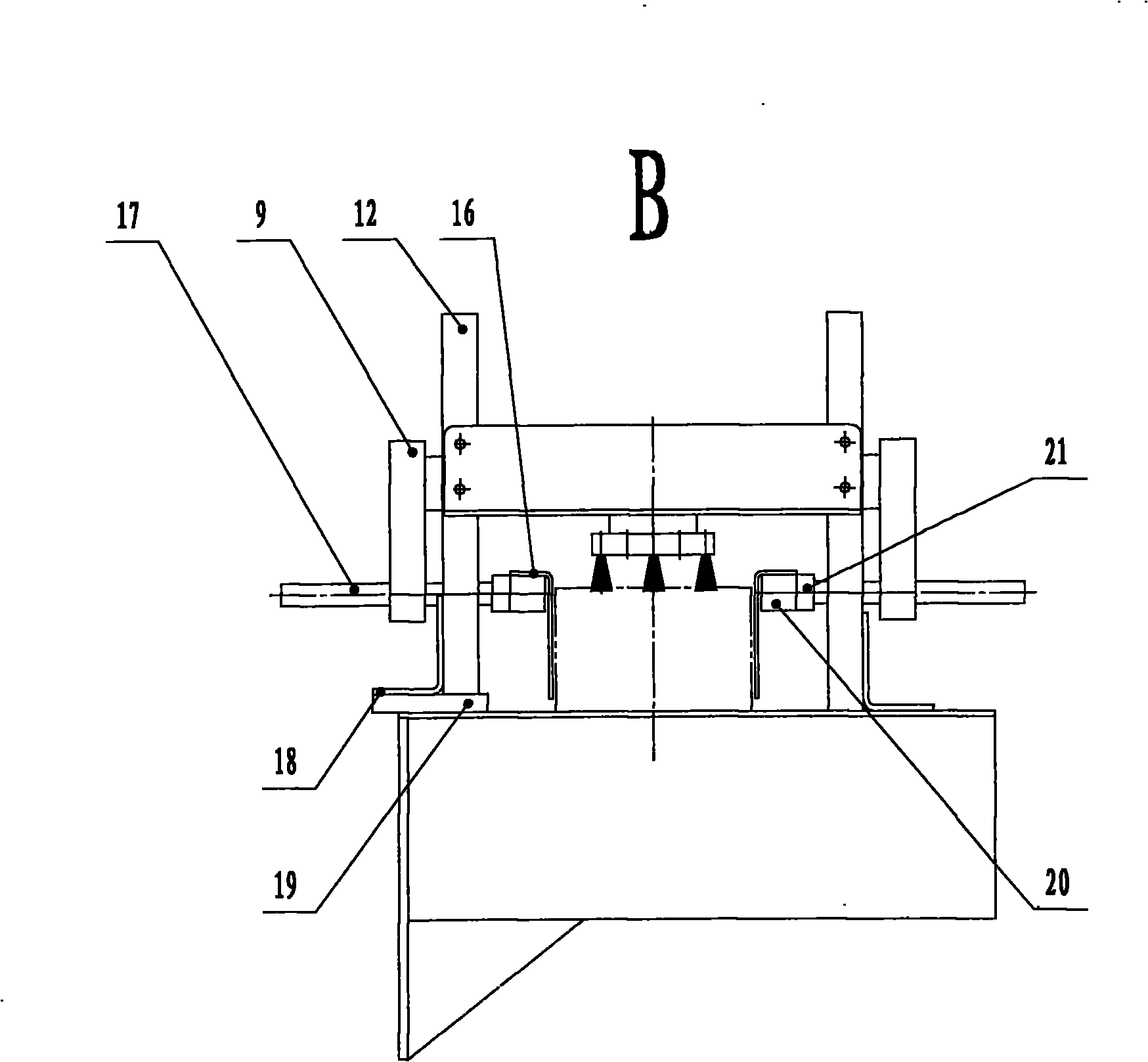

[0011] refer to figure 1 , figure 2 It can be seen that the packaging box turnover mechanism of the present invention includes an input platform 38 and a front supporting plate 24, and a runner 1 (that is, a corner 39 of the runner is embedded) is housed between the input platform 38 and the front supporting plate 24 (in an embedded manner). to the input platform and the front pallet, such as figure 2 As shown), the two sides of the runner 1 are equipped with a runner support 36, and a runner mandrel 35 is worn in the runner 1 and the runner support 36, and the runner mandrel 35 passes through the transmission assembly and the motor 29 connected; on the input platform 38 and adjacent to the runner 1, a stall proximity switch 32 (longitudinal position, on the outer side of the runner) and an in-place proximity switch 34 (horizontal position, on the runner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com