S-shaped section molding process equipment

A forming process and equipment technology, applied in the field of sheet metal parts forming, can solve problems such as cumbersome manufacturing process, inability to roll and form as a whole, and small thickness of parts materials, so as to reduce the number of process equipment, improve product production efficiency, and shorten the manufacturing process. cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings.

[0015] The forming process equipment includes two parts: a bending die and a bending chuck:

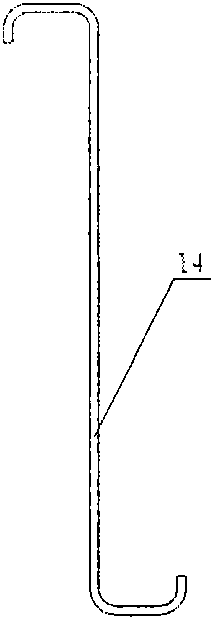

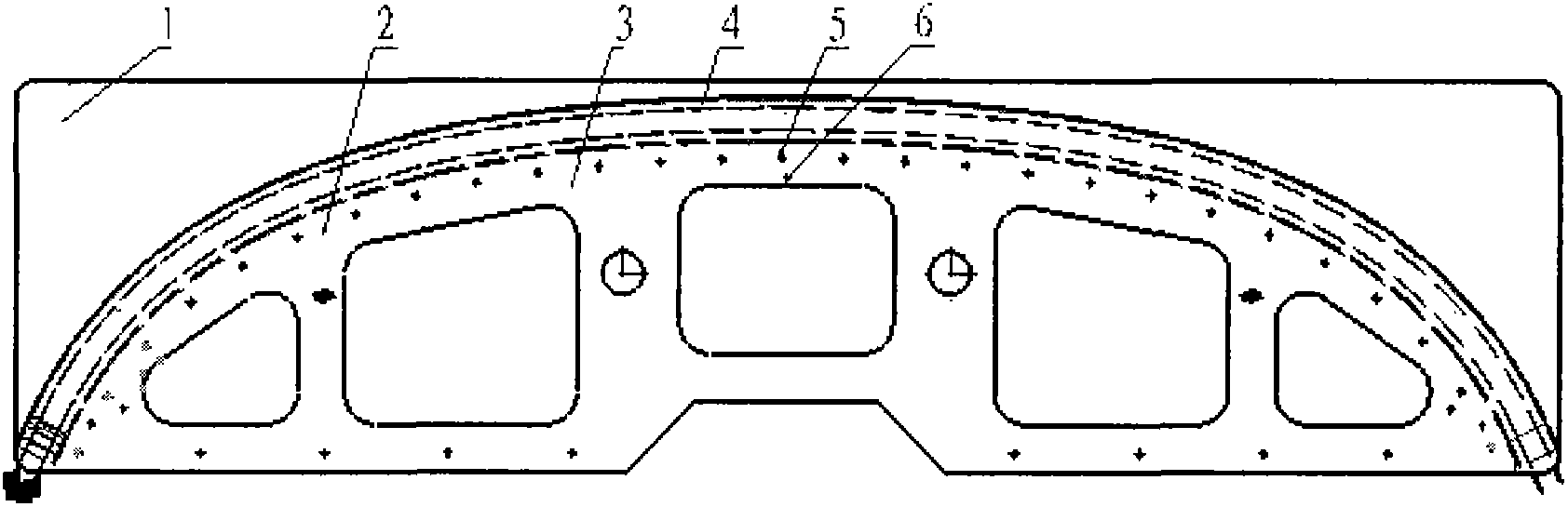

[0016] 1. The bending die consists of an upper die 1, a backing plate 2, a lower die 3, and a serpentine block assembly 4. The upper die 1 and the backing plate 2 are arc-shaped parts, and the lower die 3 is a cuboid. The length of the lower die 3 is the same as that of the upper die. 1. The chord length of the backing plate 2 is the same, and the upper die 1, the backing plate 2 and the lower die 3 are connected as a whole with screws 5 around, and fixed with pins 6 evenly along the arc length of the upper die 1. The profile 14 has the same cross-sectional dimensions, and the radian along the length direction is consistent with the radian of the S-shaped profile 14 .

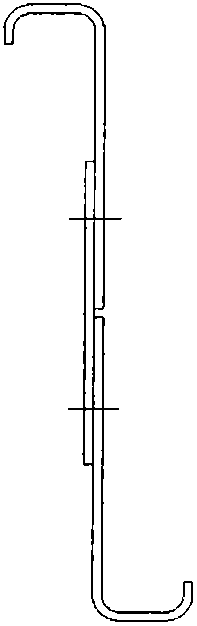

[0017] 2. The serpentine block assembly 4 is composed of a plurality of core blocks. Each core block 7 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com