Method for manufacturing super capacitor

A technology of a super capacitor and a manufacturing method, applied in liquid electrolytic capacitors and other directions, can solve the problems of separation, waste, and low yield of diaphragm active materials, and achieve the effects of improving yield, reducing work, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

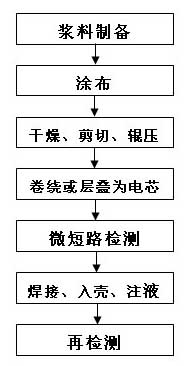

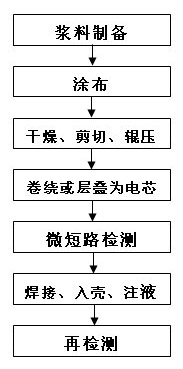

[0030] Such as figure 2 Shown, a kind of supercapacitor manufacturing method, its steps are as follows:

[0031] A. Slurry preparation: According to the conventional proportioning, the positive electrode slurry and the negative electrode slurry are prepared under the stirring process conditions; this embodiment is to prepare activated carbon, conductive agent acetylene black, binder polyvinylidene fluoride and a certain quality of solvent N-4-methylpyrrolidone was mixed, and stirred at high speed in a vacuum mixer for 18 hours to obtain a uniformly mixed slurry;

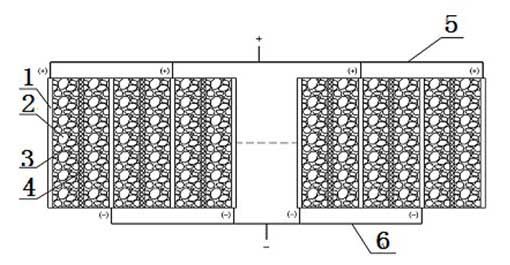

[0032] B. Coating: The positive electrode slurry and the negative electrode slurry are respectively coated on the current collector 1 by a coating process; this embodiment is coated on an aluminum foil, and the thickness is controlled to be 170 microns;

[0033] C. Drying, slicing, and rolling: first dry the current collector 1 coated with slurry to obtain positive and negative electrode sheets, then cut the obtain...

Embodiment 2

[0039] The difference from the above-mentioned embodiment 1 is that a pressure of 200 Newtons per square meter is applied to the battery core body, and the resistance value of the battery core body under a DC voltage of 200 volts is tested.

Embodiment 3

[0041] The difference from the above-mentioned embodiment 1 is that a pressure of 500 Newtons per square meter is applied to the battery core body, and the resistance value of the battery core body under a DC voltage of 100 volts is tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com