Zero-leakage type Stirling engine

A Stirling machine and zero-leakage technology, which is applied to hot gas variable displacement engine devices, mechanical equipment, machines/engines, etc., can solve the problems of inability to achieve zero leakage, small power/weight ratio, and low heat conversion efficiency. Achieve the effect of simple structure, high power/weight ratio and low material requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

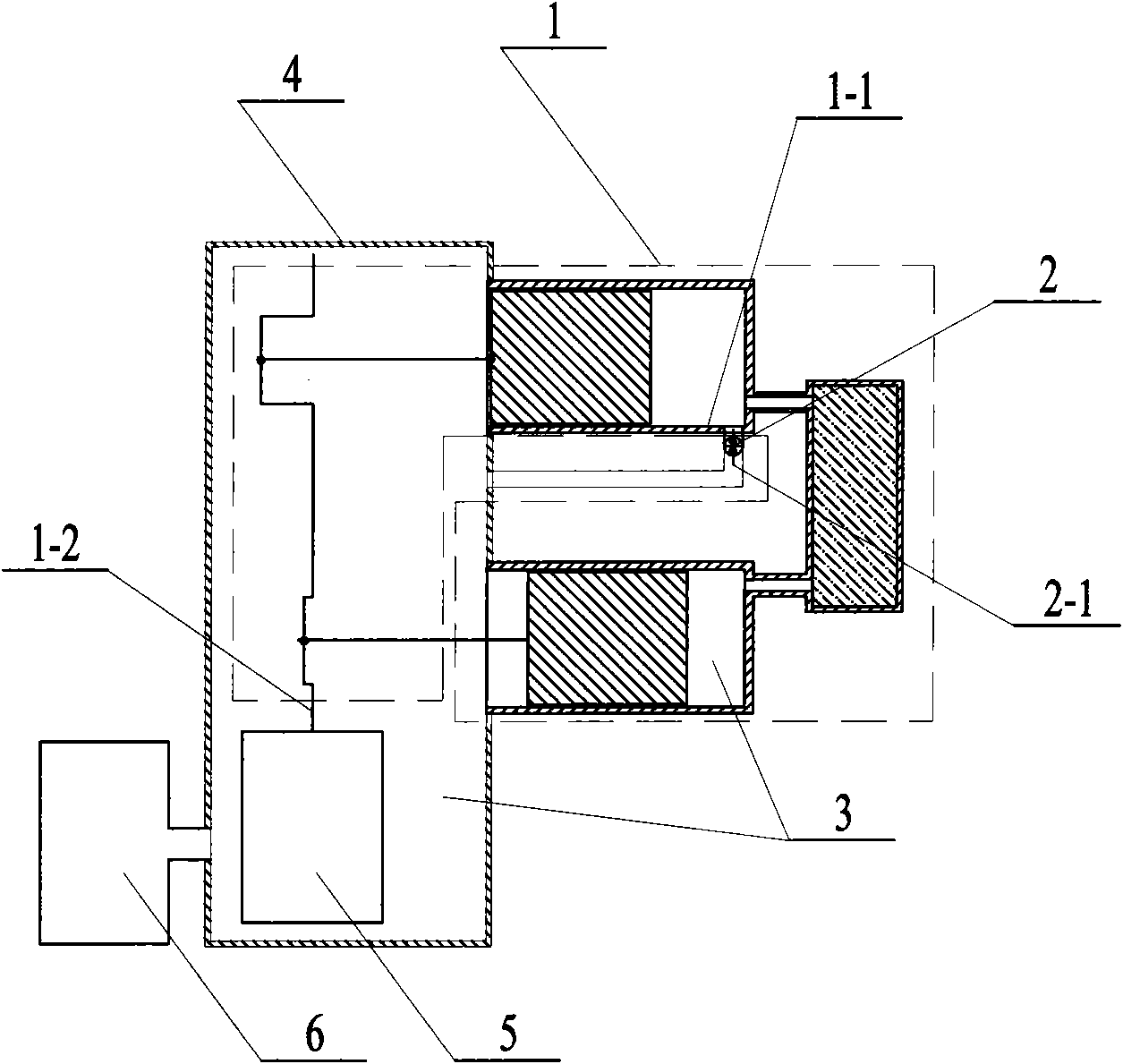

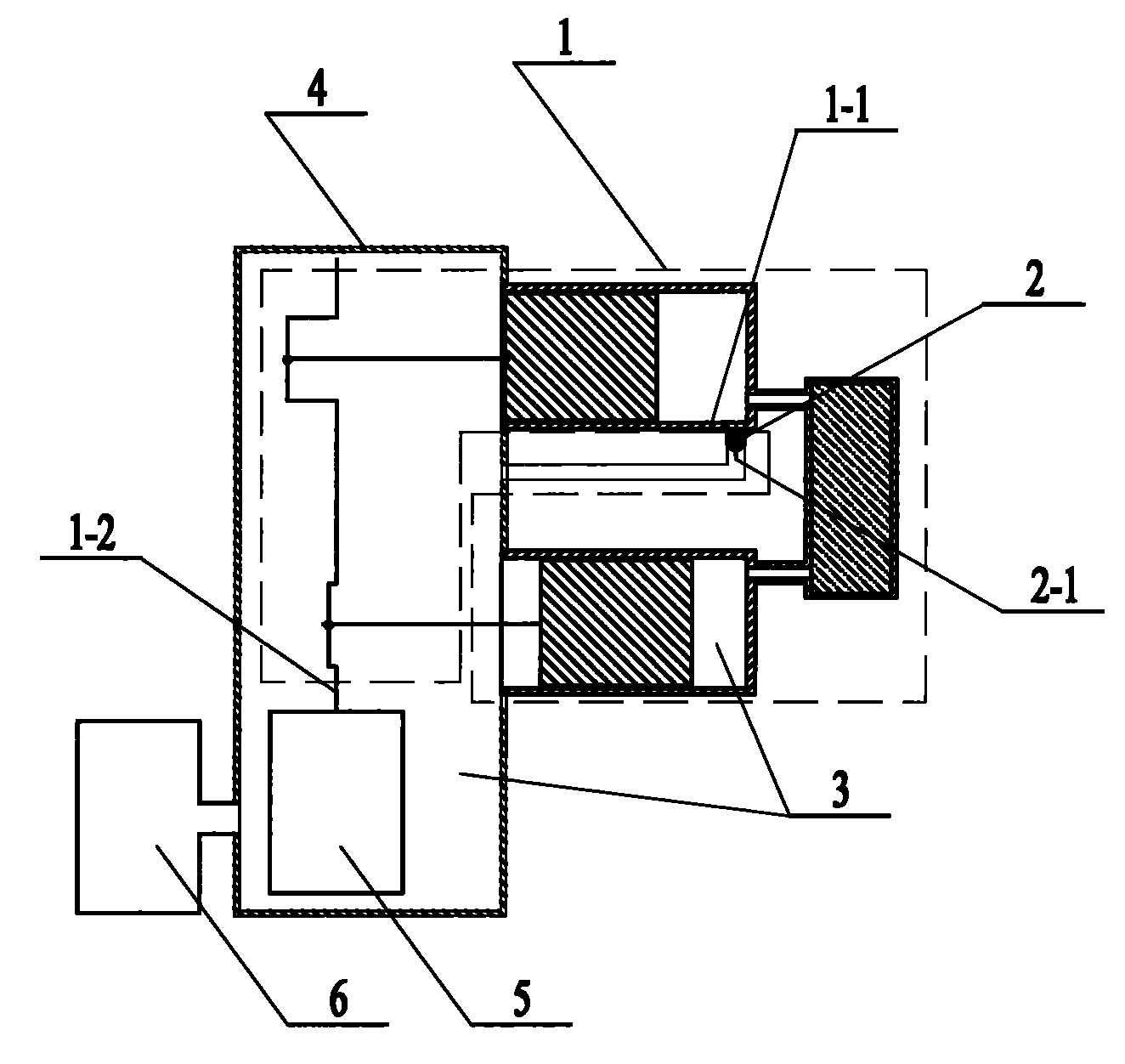

[0015] Embodiment 1: Combining figure 1 Describe this embodiment, which consists of a Stirling machine 1, a ventilation valve 2, a gas working medium 3, and an airtight casing 4;

[0016] The closed cavity 1-1 of the Stirling machine 1 is connected with an external ventilation valve 2. The conduction starting point of the ventilation valve 2 is the internal system pressure of the closed cavity 1-1 of the Stirling machine 1 is exactly equal to the external pressure. Between the value and the rotation of 20 degrees, the conduction angle of the ventilation valve 2 is 5 degrees to 25 degrees, and the movable seals of all the components of the Stirling machine 1 and the external ventilation port 2-1 of the ventilation valve 2 are closed. In a closed casing 4, the pressure of the gas working medium 3 in the closed casing 4 is 1 to 300 atmospheres (pressurized when the mechanical strength allows) or higher.

[0017] The rotating shaft 1-2 of the Stirling machine 1 can be linked with...

specific Embodiment approach 2

[0021] Specific implementation mode 2: Combining figure 1 Describing this embodiment, the difference between this embodiment and the specific embodiment 1 is that the conduction starting point of the ventilation valve 2 is the closed cavity 1-1 of the Stirling machine 1. The internal system pressure is exactly equal to the external pressure value place. Other components and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation three: combination figure 1 Describing this embodiment, the difference between this embodiment and the specific embodiment 1 is that the conduction starting point of the ventilation valve 2 is the closed cavity 1-1 of the Stirling machine 1. The internal system pressure is exactly equal to the external pressure value Rotate another 5 degrees. Other components and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com