Liquid level detection balance device used for hemodialysis

A technology for hemodialysis and liquid level detection, which is applied in dialysis systems, buoy liquid level indicators, suction devices, etc., can solve the problems of large fluctuations in pressure sensor signals, high requirements for processing accuracy of double pumps, and high cost of double pumps. Achieve the effect of simple manufacturing process and control, low manufacturing cost and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

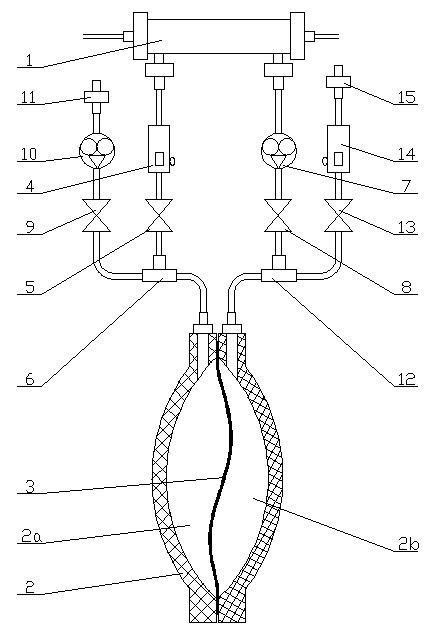

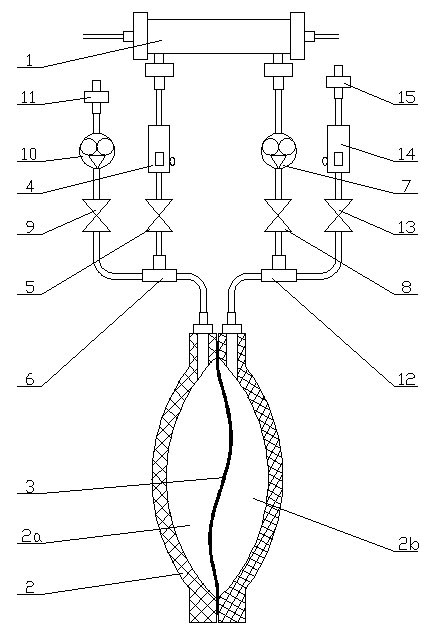

[0026] Such as figure 1 As shown, a balancer 2 is provided outside the hemodialyzer 1. The balancer 2 is composed of two symmetrical cavity hooks, and the two cavities are fixed by bolts. A diaphragm 3 is arranged in the balancer 2, the edge of the diaphragm 3 is pressed by the cavity of the balancer 2, and the diaphragm 3 separates the inner chamber of the balancer 2 into a first chamber 2a and a second chamber 2b. The outer membrane joint at one end of the hemodialyzer 1 is connected to the liquid outlet of the first liquid level detector 4 through a pipeline, and the liquid inlet of the first liquid level detector 4 is connected to the outlet of the second electromagnetic valve 5 through the pipeline. The liquid inlet of the second electromagnetic valve 5 is connected with the first end of the first three-way joint 6 through the pipeline; the outer membrane joint at the other end of the hemodialyzer 1 is connected with the inlet of the second hydraulic pump 7 through the p...

Embodiment 2

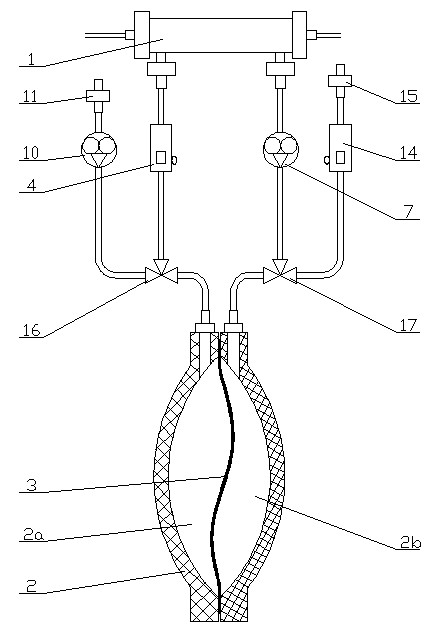

[0035] Such as figure 2 As shown, the outer membrane joint at one end of the hemodialyzer 1 is connected to the liquid outlet of the first liquid level detector 4 through the pipeline, and the liquid inlet of the first liquid level detector 4 is connected to the first three-way solenoid valve through the pipeline. 16 is connected to the liquid outlet; the outer membrane joint at the other end of the hemodialyzer 1 is connected to the liquid inlet of the second hydraulic pump 7 through the pipeline, and the liquid outlet of the second hydraulic pump 7 is connected to the second three-way electromagnetic through the pipeline. The inlet end of valve 17 is connected. The common end of the first three-way solenoid valve 16 communicates with the first chamber 2a of the balancer 2 through a pipeline, and the liquid inlet end of the first three-way solenoid valve 16 communicates with the liquid outlet of the first hydraulic pump 10 through a pipeline. The liquid inlet of the first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com