Preparation method of ultramicro traditional Chinese medicine

A traditional Chinese medicine and ultra-micro technology, which is applied in the direction of making medicines into special physical or taking forms of devices, etc., can solve the problems of low utilization rate of medicinal materials, waste of raw materials, inconvenient application, etc., to improve bioavailability and increase absorption rate. , easy to apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

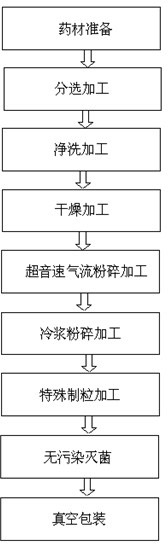

Image

Examples

Embodiment 1

[0030] Weigh 2000 grams of Magnolia officinalis, pick out other impurity medicinal materials contained in it, add it to the cleaning system, remove the dust and other impurities on the surface, and then add it to the drying system. Because it is a cold drying method, it can Keep the biological activity of the medicinal material, and then add it to the supersonic airflow pulverization system for processing. Because there will be no local overheating during the pulverization process, the pulverization is carried out at a low temperature, the speed is fast, and it can be completed in an instant, and the powder can be retained to the maximum The bioactive ingredients in the body are first pulverized in the supersonic jet pulverization system, and the pulverization particle size reaches -200 mesh, accounting for 70%, and then added to the cold slurry pulverization system for secondary pulverization, because the cold pulverization processing system is under low temperature. The speed...

Embodiment 2

[0032] Weigh 3000 grams of Eucommia ulmoides, pick out other impurity medicinal materials contained in it, add it to the cleaning system, remove the dust and other impurities on the surface, and then add it to the drying system, because it adopts the cold drying method, so it can keep The biological activity of the medicinal materials is then added to the supersonic airflow pulverization system for processing. Because there will be no local overheating during the pulverization process, the pulverization is carried out at a low temperature, the speed is fast, and it can be completed in an instant, and the powder can be retained to the greatest extent. The bioactive ingredients are first pulverized in the supersonic airflow pulverization system, and the pulverized particle size reaches -200 mesh, accounting for 65%, and then added to the cold slurry pulverization system for secondary pulverization, because the cold pulverization processing system is carried out at low temperature....

Embodiment 3

[0034] Weigh 2,500 grams of Phellodendron cortex, pick out other impurity medicinal materials contained in it, add it to the cleaning system, remove dust and other impurities on the surface, and then add it to the drying system. Because it is a cold drying method, it can keep The biological activity of the medicinal materials is then added to the supersonic airflow pulverization system for processing. Because there will be no local overheating during the pulverization process, the pulverization is carried out at a low temperature, the speed is fast, and it can be completed in an instant, and the powder can be retained to the greatest extent. The bioactive ingredients are first pulverized in the supersonic airflow pulverization system, and the pulverization particle size reaches -200 mesh, accounting for 75%, and then added to the cold slurry pulverization system for secondary pulverization, because the cold pulverization processing system is carried out at low temperature. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com